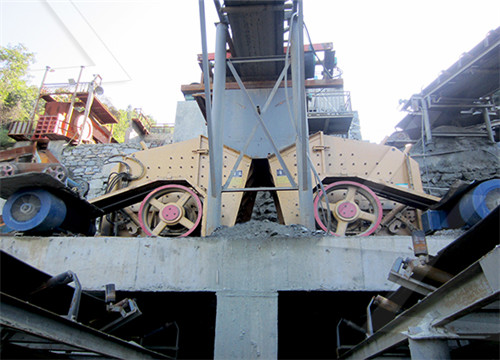

Horizontal Stone Pre Crusher

Horizontal Crushers

We have a wide range of pre-owned machines available in perfect condition, and for sale on attractive terms. Horizontal Impact Crusher HHI. With deflection-free,

进一步探索

Crusher Aggregate Equipment For Sale 1 Mach Products Hazemag North America根据热度为您推荐•反馈

mill/sbm horizontal stone pre crusher.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

horizontal stone pre crusher

Stone Products Inc. Canton, Ohio 44706. Phone (330) 462-7062. View Details. Contact Us. 1,242 HOURS, RECEIVING HOPPER 59 X 158 TOP OPENING, VIBRATING GRIZZLY

horizontal stone pre crusher

4 Types of Stone Crushers' Maintenance and . 2021-8-28 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that

horizontal stone pre crusher

Horizontal Stone Pre Crusher. horizontal stone pre crusher biologiaczlowieka.pl. 2021-4-13 horizontal stone pre crusher Crusher Wikipedia. A crusher is a machine designed to

horizontal stone pre crusher

horizontal stone pre crusher Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to FreeChat

horizontal stone pre crusher

crusher horizontal stone . Horizontal Stone Impact Crushers factjeugdnoord . Horizontal stone impact crushers crusher wikipedia a crusher is a machine designed to reduce large

horizontal stone pre crusher

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

Horizontal Shaft Impactors Astec

1 Horizontal shaft impactors (HSI) offer the adaptability and capacity required to meet producer expectations. With three- or four-bar configurations, large feed opening and high-performance MPR rotor, Astec impact crushers are well-suited for a variety of applications. With 30% more uptime and 25% more production than competitive models, our

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Rock Crushing Process in Mining Mineral

2015年7月18日 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the

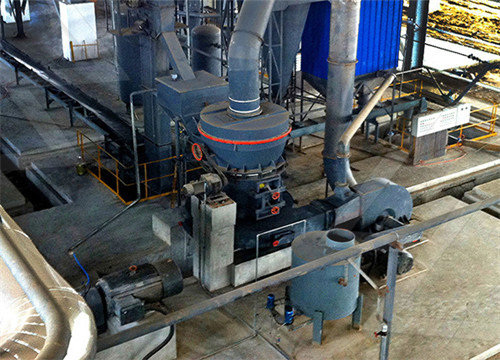

What are the cement mill pre-crushing equipment

2023年2月13日 The equipment used for pre-crushing are typically jaw crushers and gyratory crushers. Jaw Crushers: A jaw crusher uses compressive force to break down large pieces of material, such as raw

Stone crusher All the agricultural manufacturers

stone crusher with hydraulic adjustment MB-C50 S4. vineyard. The MB-C50 is the smallest crusher bucket in the MB product line, weighing less than one Ton and designed to work on excavators starting from 7 Ton. It is suitable for mini

Design and experimental research on the counter roll

The differential roller crusher is mainly designed because solid organic fertilizer is easy to agglomerate in stacking and fertilizing, and it is not easy to apply fertilizer in farmland. (stone, straw) in organic fertilizer by DEM. The shape of organic fertilizer particles is spherical, so small spherical particles with a particle size of

horizontal stone pre crusher

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

rizontal stone pre crusher,crusher machine in raipur Big

Horizontal Stone Pre Crusher podologiezentrumfritzlarde. Used 700tph Stationery Horizontal Crusher Impact 2020 4 16Used 700Tph Stationery Horizontal Crusher Impact Stone Shaft New and Used Impact Crushers for Sale Savona Equipment is an impact crusher supplier crusher is designed to work with a certain maximum size of raw material and often

Mengenal Mesin Impact Crusher Secara Mendalam CV

2021年11月22日 Jenis mesin impact crusher umumnya adalah Horizontal Shaft Impactor (HSI) dan Vertical Shaft Impactor (VSI). Walaupun desain mesin impact crusher adalah untuk menghancurkan batu, namun metodologi keduanya berbeda. Horizontal Shaft Impactors (HSI) terdiri dari hopper, dua atau tiga apron (curtain), rotor, dan hammer

Design of Impact Stone crusher machine academia.edu

Download Free PDF. Download. International Journal of ScientificEngineering Research Volume 10, Issue 5, May-2019 904 ISSN 2229-5518 Design of impact stone crusher machine Tesfaye O. Terefe, Getaw A. Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar

Horizontal Impact Crusher HHI

The HHI Horizontal Impact Crusher comprises two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the horizontal chain conveyor permits the conveyor to be utilised as both feed conveyor and discharge conveyor. This system for crushing has achieved proven success in numerous

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and 220. A high value reflects the capacity of a jaw crusher to accept large sample pieces and provide powerful crushing performance, resulting in high final fineness.

Horizontal Crushers

We have a wide range of pre-owned machines available in perfect condition, and for sale on attractive terms. Horizontal Impact Crusher HHI. With deflection-free, horizontal material flow, our HHI crushers feature an infeed/discharge chain conveyor arranged below the impact roll.

Horizontal Shaft Impactors Astec

1 Horizontal shaft impactors (HSI) offer the adaptability and capacity required to meet producer expectations. With three- or four-bar configurations, large feed opening and high-performance MPR rotor, Astec impact crushers are well-suited for a variety of applications. With 30% more uptime and 25% more production than competitive models, our

Cone Crusher For Sale Secondary Crushing Equipment

Spring cone crusher is suitable for materials: pebble, limestone, dolomite, granite, rhyolite, diabase, basalt, ferrous metals, etc. 1. Spring cone crusher is a kind of stone cone crusher widely used at present, because of its reliable operation and good performance, it is widely used in mines and gravel fields around the world. 2.

Design and experimental research on the counter roll

The differential roller crusher is mainly designed because solid organic fertilizer is easy to agglomerate in stacking and fertilizing, and it is not easy to apply fertilizer in farmland. (stone, straw) in organic fertilizer by DEM. The shape of organic fertilizer particles is spherical, so small spherical particles with a particle size of

Stone crusher All the agricultural manufacturers

stone crusher with hydraulic adjustment MB-C50 S4. vineyard. The MB-C50 is the smallest crusher bucket in the MB product line, weighing less than one Ton and designed to work on excavators starting from 7 Ton. It is suitable for mini

What Is an Impact Crusher and What Can It Do for You?

2021年1月10日 Used in a wide variety of applications, including aggregate crushing, asphalt crushing, and concrete crushing, etc., an impactor is unique to its crusher counterparts in that it breaks apart rocks and stones by rapidly striking the material as opposed to utilizing a pressure force. The mechanical structure of an impact crusher is

Design of Impact Stone crusher machine academia.edu

Download Free PDF. Download. International Journal of ScientificEngineering Research Volume 10, Issue 5, May-2019 904 ISSN 2229-5518 Design of impact stone crusher machine Tesfaye O. Terefe, Getaw A. Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar

Jaw Crusher Handbook Stone Crusher PDF

The crusher is installed on the pre-made Foundation (the foundation should be well laid), the crusher finds a good level. The base plate and the foundation are left about a 20mm gap filled with cement mortar. Then