Dense Media Separator For Sale

Condor Dense Medium Separators Mineral

Condor Dense Medium Separator. Condor Dense Medium Separators provide a simple, cost-effective way to separate and recover valuable

Dense Medium Separator (DMS) Sepro Labs

2016年4月24日 Dense medium separation (DMS), also known as dense or heavy media separation, is a beneficiation technology that has been used for many years in the

Researching Preconcentration with Mineral Processing

THE CONDOR DENSE MEDIA SEPARATOR. The Condor Dense Media Separator has gained interest as an effective and successful preconcentration technology that applies a

Heavy media separation LKAB Minerals

Benefits of using Magnetite in dense medium separation. For many heavy media separation processes, the right slurry density can be reached with Magnetite. The particle density of

Dense-Heavy Medium Separation HMS / DMS Process

2015年6月23日 Dense medium separation (or heavy medium separation (HMS), or the sink-and-float process) is applied to the pre-concentration of minerals, i.e. the rejection of

Mineral Processing Dense Media Separation Bond

DENSE MEDIA SEPARATION (DMS) PLANTS. The DMS process is employed for the pre-concentration of suitable ores upstream from expensive downstream metallurgical

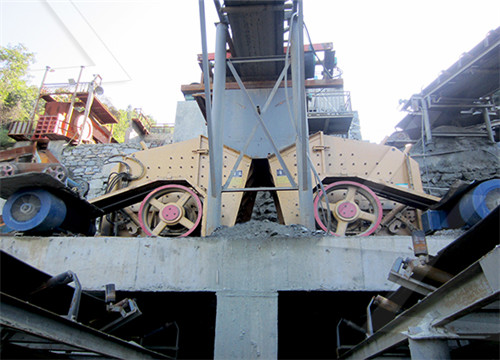

WEMCO DENSE MEDIA SEPERATOR for sale

WEMCO DENSE MEDIA SEPERATOR for sale POA. Screening and Crushing / Screening Crushing / Separator. CALL 02 6171 3897 Title: WEMCO DENSE MEDIA SEPERATOR:

fr/wemco heavy media drum separator spécifications.md

Nov 10,2012 Heavy Media Separation ManufacturerWholesale Supplier From.The WEMCO® Heavy Media Drum Separator is probably the world's best known processor

Heavy Media Drum Separators Multotec

The Multotec Heavy Media Drum Separator (HMDS) improves grade and recovery in dense medium recovery processes. Multotec improves the performance of dense media mineral recovery operations through combining internationally-leading Permax technology, an established application- and context-specific experience in mineral processing and

Heavy Media Separation Process (ferrosilicon) DMS

Dense Medium Separation (also called Heavy Media Separation) is a well-established density separation process. Dense Medium Separation (DMS) uses the characteristic differences in density of the input material to enact a gravimetric-based separation. Due to the robustness of the process, DMS can be used in the separation of minerals, ore

Mineral Processing Dense Media Separation Bond

DENSE MEDIA SEPARATION (DMS) PLANTS. The DMS process is employed for the pre-concentration of suitable ores upstream from expensive downstream metallurgical processes, and also employs the separation of heavy waste particles (such as metals) from light waste particles. Process description DMS cyclone plants. The DMS process

Dense-Heavy Medium Separation HMS / DMS Process

2015年6月23日 Dense medium separation (or heavy medium separation (HMS), or the sink-and-float process) is applied to the pre-concentration of minerals, i.e. the rejection of gangue prior to grinding for final liberation. It is also used in coal preparation to produce a commercially graded end-product, clean coal being separated from the heavier shale or

Heavy Media Separation Process Mineral

2016年5月22日 The heavy-media separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sink-float separations. A stable medium over the range

HEAVY MEDIA DRUM Malvern Engineering

HEAVY MEDIA DRUM indetail 2019-09-02T13:49:22+00:00 HEAVY MEDIA DRUM The Malvern Engineering Heavy Media Drum (HMD) is used for heavy media separation of feed materials within a range of 10mm to 300mm particle size.

Low-density Separation Techniques Recover

2021年4月5日 There are three ways to make a lower cut in the fines circuit: the use of a teetered-bed separator (TBS) or a REFLUX Classifier (RC), low-density spiral concentrators or a fine dense-media-cyclone (DMC)

(PDF) Dense Medium Separation (DMS)

Feed medium, required relative density is introduced under pressure, either by pump or static head, into the involute tangential Dense medium separation (DMS) 253 LARCODEMS Plant in Operation Dyna Whirlpool

crusher/sbm heavy media separator unit sell.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

fr/wemco heavy media drum separator spécifications.md

Nov 10,2012 Heavy Media Separation ManufacturerWholesale Supplier From.The WEMCO® Heavy Media Drum Separator is probably the world's best known processor for dense media separation of coal and minerals in the size range of 300.?More detailedClassification and centrifugation Drum separators Heavy media drum

Heavy Media Separation Process (ferrosilicon) DMS

Dense Medium Separation (also called Heavy Media Separation) is a well-established density separation process. Dense Medium Separation (DMS) uses the characteristic differences in density of the input material to enact a gravimetric-based separation. Due to the robustness of the process, DMS can be used in the separation of minerals, ore

Dense Media Separation SpringerLink

The processes considered in this chapter are variously called “sink-float”, “sink-and-float”, “dense-medium separation”, “heavy-medium separation” and “heavy-liquid separation” in response to their variations on the basic principle of dense media separation (usually abbreviated to DMS).*. They may include: Separation in a

HEAVY MEDIA DRUM Malvern Engineering

HEAVY MEDIA DRUM indetail 2019-09-02T13:49:22+00:00 HEAVY MEDIA DRUM The Malvern Engineering Heavy Media Drum (HMD) is used for heavy media separation of feed materials within a range of 10mm to 300mm particle size.

The art and science of dense medium selection

Heterogeneous suspensions such as those used for dense media tend to have a yield stress. The quantity of solid phase in the suspension is defined by the density of the suspension and is commonly referred to as the

WEMCO DENSE MEDIA SEPERATOR for sale

WEMCO DENSE MEDIA SEPERATOR for sale POA. Screening and Crushing / Screening Crushing / Separator. CALL 02 6171 3897 Title: WEMCO DENSE MEDIA SEPERATOR: Make: WEMCO: Price: POA : Listing Type: Used: Stock Number: MQP005: Refcode: TADPLIn24704: WEMCO Dense media seperator 4500mm x 7000mm dual compartment

(PDF) Dense Medium Separation (DMS)

Feed medium, required relative density is introduced under pressure, either by pump or static head, into the involute tangential Dense medium separation (DMS) 253 LARCODEMS Plant in Operation Dyna Whirlpool

Dynamic dense media separator Sala International AB

What I claim is: 1. In a dynamic dense media separator comprising a cylindrical separation vessel having an axial outlet for separated material fractions of a lower density, at one end of said vessel, an inlet for dense media on the cylindrical surface of the separation vessel at the same end thereof as said outlet, and an axial inlet for material to be separated, at the

DENSITY SEPARATORS Classification and Flotation Systems

The CFS Density Separator is a hydraulic classification device consisting of an upper paralleled-walled section of square or rectangular cross-section, and a. PH. (800) 666 0154. Email: cfs@cfs-web. Menu HOME. FRAC SAND PLANTS. DENSITY SEPARATORS. Density Separator. Principles of Operation. How it Works.

dense media separator for sale chinagrindingmill.net

Grinding Solutions. Grinding is the required process when size reduction of below 5-20 mm is needed.Grinding is a powdering or pulverizing process, and it can use three methods. Crushing Solutions. From large primary jaws and gyratories to cones and impacts for tertiary and quaternary finishing, Gulin has the right crusher and crusher parts ? Copper

Ense Media Separation For Sale, Hot Products

Heavy Media Separation Using Tetrabromoethane. ultra clean coal production using dense medium separation for the silicon market seyed hassan amini university of kentucky imitation of media density values using various solids 39 t able 32 d ense medium cyclone pressure required to maintain 9 d c at various. Online Chat Ultra Clean Coal