High Amplitude Vibrating Screens

Discrete element modelling of vibrating screens

2018年6月1日 These parameters have significant importance in the design of vibrating screens as they determine the motion of the screen surface and have a considerable influence on particle–particle and particle–surface collisions. During the tests the screen

Benefits of high frequency vibrating screen in gold

The common issues associated with the vibrating screens currently available on the market are: poor sealing between the screen moving frame and chute work; blinding of the

sbm/sbm high amplitude vibrating screen.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Why a Vibrating Screen? MEKA

The body of MEKA screens is resistant to vibration. Screens materials thanks to effect of mechanical vibration. The body of the screen is vibrated by a vibration mechanism, causing the whole screen to shake. The

What is the difference between vibrating screens and

2023年3月10日 4. Different forms of sieve surface. The vibrating screen is a horizontal or downward sieve surface to facilitate discharge. The screen surface of the dehydration

Vibrating Screen Working Principle Mineral

2015年7月26日 Four-Shaft Horizontal Screens with eight 130mm through 160mm bearings. d. Six Shaft Horizontal Screens with twelve 130mm bearings per vibrator vibrating 82,000 pounds. e. Inclined Screens with

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

Vibrating Screen High Frequency Vibrating Screen

Circular vibrating screens are medium amplitude devices that come with an ordinary motor and based on the characteristics of the particle, amplitude and frequency of the device

Benefits of High Frequency Vibrating Screens in Gold

2022年4月5日 FIG 2 Comparison between support structures for conventional screens and high frequency screens. The smaller footprint of the HFLS enables the development

Simulation of particles motion on a double vibrating flip

2023年3月8日 The surfaces of vibrating flip-flow screens have the advantages of high vibration intensity, non-blocking holes, easy depolymerization of clustered particles, and self-cleaning functionality, which are widely used in the classification of wet fine-grained granular materials. Yu Chi used DASP to measure the amplitude of each point of the

Discrete element modelling of vibrating screens

2018年6月1日 These parameters have significant importance in the design of vibrating screens as they determine the motion of the screen surface and have a considerable influence on particle–particle and particle–surface collisions. During the tests the screen inclination was kept constant at 10°. 3.3.1. Vibration amplitude.

Applied Sciences Free Full-Text A Study on the Dynamic

Various vibrating screens are often applied in various industries, e.g., mining, agriculture, and others. The complex shapes of the screen trajectories in the oscillating motion strongly affect the best processing properties of such machines. One of the possible methods for obtaining such complex shapes is the application of double-frequency vibrators on such

Chinese Physics C, Volume 38, Number 11, November

For 100 μm, 200 μm and 300 μm thick CsI screens, the DQE under RQA7 and RQA9 is lower than that under RQA3 and RQA5 due to low absorption efficiency. can achieve very high alignment accuracy. The vibrating wire alignment technique can be applied to fiducializing magnets and the alignment of accelerator straight section components, and it

Optimization of the Vibrating Machines with Adjustable

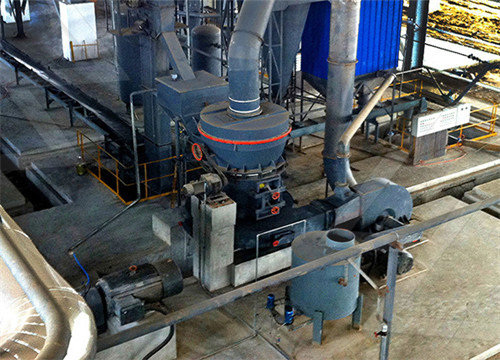

amplitude, which may change significantly as a result of changing load conditions. Fig. 1. Resonant vibrating screen GRK-82: 1 frame; 2 the vibrator; 3 the elastic coupling of

Current status and application of fine screening

2017年10月1日 The stone presents data on the design and technical parameters of high frequency vibrating screens, which are produced by Chinese manufacturer company Landsky Tech Ltd. The technology of high

Acoustic touchless sensor using the flexural vibration of a

2023年2月14日 An acoustic touchless sensor with a simple configuration was fabricated. Figure 1 shows the configuration of this ultrasonic sensor, which consists of a rectangular plate and two ultrasonic transducers. Two bolt-clamped Langevin-type transducers (BLTs; length: 95 mm; diameter: 30 mm; resonance frequency: 25.5 kHz) were connected to

What is the difference between vibrating screens and

2023年3月10日 4. Different forms of sieve surface. The vibrating screen is a horizontal or downward sieve surface to facilitate discharge. The screen surface of the dehydration screen is mostly upward climbing

Vibrating Screen Market Key Players are Adopting

1 “Vibrating screens are becoming more standardised and used for material segregation applications. “These devices offer high purity and sizing separations for industrial applications such as powder processing, dewatering materials, fractionating reclaimed asphalt pavement, and pelleting, which will drive growth in the coming

Banana Vibrating Screen

2022年6月14日 Large screen openings for large cuts can be achieved with high amplitude and low speed. For small screen openings for finer cuts, the opposite is true: low amplitude and high speed.With many years' export experiences, our Fine Vibrating Screen, China Vibrating Screen For Sale,Medium Size Material Vibrating Screen has been welcomed in

Simulation of particles motion on a double vibrating flip

2023年3月8日 The surfaces of vibrating flip-flow screens have the advantages of high vibration intensity, non-blocking holes, easy depolymerization of clustered particles, and self-cleaning functionality, which are widely used in the classification of wet fine-grained granular materials. Yu Chi used DASP to measure the amplitude of each point of the

Stepwise shape optimization of the surface of a vibrating

2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

Applied Sciences Free Full-Text A Study on the Dynamic

Various vibrating screens are often applied in various industries, e.g., mining, agriculture, and others. The complex shapes of the screen trajectories in the oscillating motion strongly affect the best processing properties of such machines. One of the possible methods for obtaining such complex shapes is the application of double-frequency vibrators on such

Optimization of the Vibrating Machines with Adjustable

amplitude, which may change significantly as a result of changing load conditions. Fig. 1. Resonant vibrating screen GRK-82: 1 frame; 2 the vibrator; 3 the elastic coupling of

sbm/sbm high amplitude vibrating screen.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Analysis of the dynamic forces acting on a vibrating screen

2021年5月1日 The designed equipment presented in this work is a vibrating dewatering screen, model PVD 1206 1 A (Fig. 1), with a nominal length of 1200 mm and nominal width of 600 mm, which was developed with the upper double mechanism, driven by two motors via cardans [1].Its two mechanisms at the top, with unbalanced masses, cause a

Current status and application of fine screening

2017年10月1日 The stone presents data on the design and technical parameters of high frequency vibrating screens, which are produced by Chinese manufacturer company Landsky Tech Ltd. The technology of high

What is the difference between vibrating screens and

2023年3月10日 4. Different forms of sieve surface. The vibrating screen is a horizontal or downward sieve surface to facilitate discharge. The screen surface of the dehydration screen is mostly upward climbing

Vibrating Screen Market Key Players are Adopting

1 “Vibrating screens are becoming more standardised and used for material segregation applications. “These devices offer high purity and sizing separations for industrial applications such as powder processing, dewatering materials, fractionating reclaimed asphalt pavement, and pelleting, which will drive growth in the coming

Acoustic touchless sensor using the flexural vibration of a

2023年2月14日 An acoustic touchless sensor with a simple configuration was fabricated. Figure 1 shows the configuration of this ultrasonic sensor, which consists of a rectangular plate and two ultrasonic transducers. Two bolt-clamped Langevin-type transducers (BLTs; length: 95 mm; diameter: 30 mm; resonance frequency: 25.5 kHz) were connected to