High Efficient Wet Grinding Hammer Mill

Granulex 5 Series hammer mill group

Granulex 5 Series hammer mill Granulex® 5 Series In addition to exceptional efficiency and ease of maintenance, our Granulex 5 Series is characterized by its high throughputs. Distinguished by flexibility, each

Laboratory Mills PerkinElmer

Hammer mills The hammer mills grind by means of a high-speed rotating steel "hammer" and has a sieve in the periphery through which the sample leaves the

进一步探索

Laboratory Mill 3100 Prairie Ag ProductsLab Mill 3100 PerkinElmer根据热度为您推荐•反馈

RudnickEnners hammer mills as wet chip mill

Wet hammermill Positioned within a noise- isolated container Wet hammermill for milling the input material to a dryable particle size without additional air aspiration system

Hammer Mills, for All Your Grinding Needs Meadows Mills

Parts for all Meadows hammer mills may be purchased by contacting Meadows Mills directly. We are happy to evaluate any product free of charge. If you are interested in

Back to Basics Hammer Milling and Jet Milling

A hammer mill is typically good for grinding softer materials with Mohs hard-ness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High

Efficient Flour Grinding with a Hammer Mill

The Mikro Pulverizer® HammerScreen Mill is a high speed mechanical impact mill designed for continuous size reduction of a wide range of soft to medium-hard materials

Hammer Mills GHM Anderson Feed Technology

Hammer Mills GHM Over 100 years of experience and innovation have led to the development of a wide range of high-efficiency Hammer Mills GHM for a variety of applications. The GHM series Hammer Mills are

Hammer mill (green materials) Bruks Siwertell

Bruks high-capacity hammer mills for green grinding have been specially designed to handle the increased moisture content of these products. Their heavy-duty construction effectively and efficiently grinds

FEED AND BIOFUEL HIGH PERFORMANCE GRINDING

density products. The hammer mills have a directly coupled motor mounted on a base frame. The front doors are bot-tom-hinged and open on sliding rails. All operating points

MultimpactFine AUBK Hammer mill

’s services and training are designed to keep you up-to-date on products and technologies, giving you the confidence and experience you need. Assessments and consulting Towards a successful future. Contact

Granulex 5 Series hammer mill group

Granulex 5 Series hammer mill Granulex® 5 Series In addition to exceptional efficiency and ease of maintenance, our Granulex 5 Series is characterized by its high throughputs. Distinguished by flexibility, each

Laboratory Mills PerkinElmer

The hammer mill is typically used to produce a fine and homogeneous sample. The Perten Instruments hammer mills can grind up to 300-gram samples which is the requested amount in for example the Falling Number test. Because of the heat development in the grinding operation and the high air flow through the grinding chamber this type of mill is

Optimizing hammer mill performance through screen

of finely grinding the greatest variety of materials [3,13] and are noted for achieving high size-reduction ratios and yielding cubic-shaped particles [14,15]. Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16]. Fine or especially difficult to grind materials are

RudnickEnners hammer mills as wet chip mill

RudnickEnners wet chip mills are designed for the wet grinding of chips or lumpy biomass. The starting material can be ground to a particle size suitable for drying or agglomeration. Depending on the machine configuration and input material, throughput rates of up to 130 loose cubic metres/h are possible (subject to detailed examination of your

Wet Milling vs Dry Milling: The Differences,

2021年6月17日Now that we have a basic understanding of the industrial milling process, let’s examine the difference between wet milling and dry milling. Dry milling typically uses particle-on-particle contact to reduce

Full article: Optimizing hammer mill performance through

2014年4月9日Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatility . Fine or especially difficult to grind materials are often best comminuted using high-speed hammer mills

Wet mill, Wet grinding system All industrial manufacturers

vertical for granite soybean. Output: 1 kg/h 3,000 kg/h. Motor power: 4, 15, 22 kW. Machine width: 350, 600, 750, 850 mm. The GRANOMAT JP disk mill is designed for the ultrafine grinding of numerous products. It is also described as a ‘dissolving machine’ and can be used for both wet and dry milling.

Back to Basics Hammer Milling and Jet Milling

A hammer mill is typically good for grinding softer materials with Mohs hard-ness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materi-als become very abrasive; therefore, they are not suitable for high-speed hammer mills. In a typical jet mill, grinding

What type of crushing machinery to choose for coal grinding?

2023年3月9日Hammer Mills: Hammer mills are a popular choice for coal grinding because they can handle both dry and wet materials. They work by crushing the material with a series of rotating hammers, which

Hammer Mills For Efficient Grinding TIETJEN

high speed hammer mills with a smaller print and grinding chamber areas from 0.3 to 1.9 m² Individual solutions for our customers THE SPECIAL Features of our HAMMER MILLS Durable, reliable and efficient machines Our mills or grinders are “made in Germany”. We use only high-quality components, such as our 6-axis rotor design.

Hammer Mills, for All Your Grinding Needs Meadows Mills

Parts for all Meadows hammer mills may be purchased by contacting Meadows Mills directly. We are happy to evaluate any product free of charge. If you are interested in sending a product for evaluation please contact Brian at 1-800-626-2282 or 336-838-2282. By evaluating your product we are able to prove the capability of our hammer mills and

Hammer Mills GHM Anderson Feed Technology

The GHM series Hammer Mills are equipped with adjustable breaker plates to allow for efficient grinding in both directions. Placing the break plates at two different locations creates an assymetric grinding action resulting in higher impact forces, less wear on the screens, and a more consistent flow of product through the grinding chamber.

Energy consumption of two-stage fine grinding of Douglas-fir

2018年3月12日The hammer mill has 32 pieces of swing hammer of 6.4 × 50.8 × 120 mm on a 610-mm diameter rotor. The tip of the hammers reaches a linear speed of 115 m/s. The air flow rate of the blower is 63 m 3 /min. The total rated power of the hammer mill circuit was 42 kW (Table 1 ).

Granulex 5 Series hammer mill group

Granulex 5 Series hammer mill Granulex® 5 Series In addition to exceptional efficiency and ease of maintenance, our Granulex 5 Series is characterized by its high throughputs. Distinguished by flexibility, each

Optimizing hammer mill performance through screen

of finely grinding the greatest variety of materials [3,13] and are noted for achieving high size-reduction ratios and yielding cubic-shaped particles [14,15]. Hammer mills have a wide application in biomass size reduction because of their simple design, ruggedness and versatil ity [16]. Fine or especially difficult to grind materials are

Laboratory Mills PerkinElmer

The hammer mill is typically used to produce a fine and homogeneous sample. The Perten Instruments hammer mills can grind up to 300-gram samples which is the requested amount in for example the Falling Number test. Because of the heat development in the grinding operation and the high air flow through the grinding chamber this type of mill is

RudnickEnners hammer mills as wet chip mill

RudnickEnners wet chip mills are designed for the wet grinding of chips or lumpy biomass. The starting material can be ground to a particle size suitable for drying or agglomeration. Depending on the machine configuration and input material, throughput rates of up to 130 loose cubic metres/h are possible (subject to detailed examination of your

Hammer Mills and Material Size Reduction Equipment

Important features of Prater Full-Screen Hammer Mills include: Durable, heavy-duty fabrication designed for superior operation and long lifespan. 100% of screen utilized for maximum efficiency. A variety of hammer

Wet Milling vs Dry Milling: The Differences,

2021年6月17日We are a leader in the Wet Grinding and Dispersion Industry and offer custom designed processing equipment for mixing, blending, dispersing, and particle size reduction. The Hockmeyer team is

Vertica series hammer mill GROUP

Vertica series hammer mill With no external aspiration required, 's Vertica hammer mill can reduce energy consumption by up to 25%. Its small footprint as well as the change-over and hygiene benefits make it ideal for the feed, grain and oil milling and biomass industries. :products/businessunit/pc032_1005 CUBE-00008-602 Solutions

Hammer Mills GHM Anderson Feed Technology

The GHM series Hammer Mills are equipped with adjustable breaker plates to allow for efficient grinding in both directions. Placing the break plates at two different locations creates an assymetric grinding action resulting in

Wet mill, Wet grinding system All industrial manufacturers

FRITSCH Planetary Ball Mills high-performance all-rounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations is the ideal mill for sample preparation mill PULVERISETTE 11 knife vertical Rotational speed: 2,000 rpm 14,000 rpm

What type of crushing machinery to choose for coal grinding?

2023年3月9日Hammer Mills: Hammer mills are a popular choice for coal grinding because they can handle both dry and wet materials. They work by crushing the material with a series of rotating hammers, which

Hammer Mills For Efficient Grinding TIETJEN

high speed hammer mills with a smaller print and grinding chamber areas from 0.3 to 1.9 m² Individual solutions for our customers THE SPECIAL Features of our HAMMER MILLS Durable, reliable and efficient machines Our mills or grinders are “made in Germany”. We use only high-quality components, such as our 6-axis rotor design.

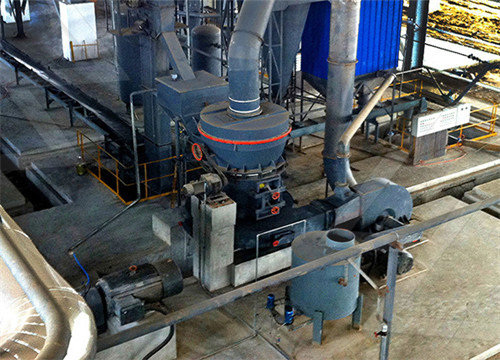

Hammer mills ANDRITZ

The Optimill series consists of hammer mills that can be applied for grinding of raw materials for normal to coarse structured products. Key features: Coarse-grained particles optimum particle size range Patented closed rotor design saving up to 20% in energy consumption Large screen area 1,500-1,800 rpm Reduced noise level

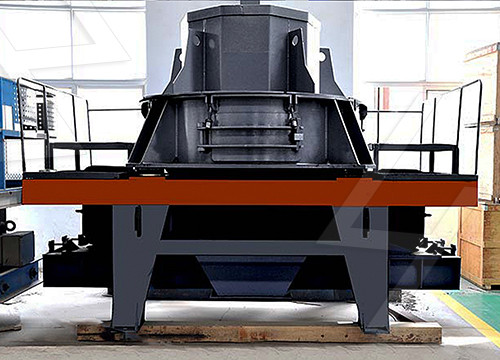

hammer mill ,rock grinding machine walker mining

2021年5月7日Looking for a hammer mill ,rock grinding machine supplier ? View and compare products from top manufacturers. The hammer mill was developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, petroleum and chemical industries.

Hammer Mills for Material Reduction Williams Patent Crusher

The Traveling Breaker Plate Mill is a non-clog hammer mill. This engineering allows a Slugger Crusher to reduce rock, clay, shale, and bauxite to less than ¾”. It can reduce wet, sticky materials to a size suitable for further refinement. This machine’s self-cleaning breaker plates reduce maintenance and service costs.

- 迁西脱水振动筛

- Crusher Ballast Ore

- HP400型圆锥破碎机价格

- 红红350v效率快速粉碎机

- 振动流化床干砂机

- 中速磨直吹装置原理放電発光分光分析装置

- Stone Crushers In Sa

- ch870圆锥破碎机性能参数

- Gold Impact Crusher For Sale Zimbabwe

- 电厂水渣机底门

- Gra Lego Hero Faktory Jungle Mining Mill

- 河南反击破碎石机碎石工作原

- 西安对辊破碎机

- New Cone Plant Rock Crusher

- App Like Grindr For Straight People Android