Layouts Zinc Recovery Plants

ITACOR Zinc ash recovery

ITACOR designs and builds zinc ash recovery plants with production of secondary zinc with maximum purity of 99.2% and zinc oxides. Contact us Other categories of

Plant engineering for zinc recovery AIK Technik AG

Zinc recovery (FLUREC) Processes in the fly-ash sector. Do you have any questions about the plant engineering of FLUREC (zinc recovery) and the process used for it?

A novel process to recover cadmium and zinc from the

2017年12月1日Plants of N. caerulescens (population ‘Ganges’, from St Laurent-le-Minier, S. France) were grown on surface soil collected from an industrial site sampled 500 m

BULGARIA ZINC RECOVERY (WAELZ) PLANT YouTube

2022年5月20日BULGARIA ZINC RECOVERY (WAELZ) PLANT YouTube BULGARIA ZINC RECOVERY (WAELZ) PLANT BULGARIA ZINC RECOVERY (WAELZ) PLANT

Silver Lead Zinc Ore Processing Method using Flotation

2016年4月20日The flowsheet is for a plant having a capacity in the range of 300 to 500-tons per day. A Pb-Ag-Zn Separation Circuit Flowsheet #1 Crushing Section The crushing section of this 50-65 ton mill consists of a

Recovery of zinc and lead from zinc plant residue

2004年11月1日Zinc and lead recovery from zinc plant residue (ZPR) has been investigated. The residue is discarded as a cake from a Waelz kiln processing zinc–lead

Processing for extraction of valuable metals from zinc

2010年1月1日condition for extraction of lead and zinc from lead bearing ZPR of NILZ plant. At zinc recovery stage by . diluted sulfuric acid solution, the corresponding recoveries were as 0.1% Pb, 19.7% Zn

Recovery of Zinc from Effluent of Plants and Mines IIENG

In this stone the recovery of zinc from plants and mines effluent, using the solvent extraction is discussed. metalsSuccessful . usage of solvent extraction as a method to

Oxidative damage of workers in secondary metal recovery

In Taiwan, secondary copper smelters and zinc recovery plants primarily utilize recovering metal from scrap and dross, and handles mostly fly ash and slag with high temperature

Zinc Plant Expansion and Modification for Increased Metals Recovery

2020年1月25日Due to increasing demand for this metal, the plant annual capacity was increased to 240,000 ton in 2006. The production of zinc concentrates with high iron content by Peñoles mines also increased; however, the main characteristic of these materials is the lower recovery of zinc in the roasting –leaching –electrowinning process.

National Renewable Energy Laboratory (NREL) Home Page NREL

National Renewable Energy Laboratory (NREL) Home Page NREL

Pb Recycling Through Leaching, Precipitation, and Cementation from Zinc

2021年2月23日Abstract This stone presents the hydrometallurgical methods used for the recovery of concentrate and metallic lead from zinc plant residue (ZPR). The ZPR mainly consisting of 9.5% Pb and 7.5% Zn was initially leached by sulfuric acid under the following conditions: leaching temperature 90 °C, leaching time 90 min., sulfuric acid concentration

HoriZn Technologies HoriZnTech EAF Dust Recycling Israel

HoriZnTech’s laboratory and pilot plant are situated in Acker, Israel. Our zinc recovery process now routinely produces high purity metallic zinc powder from 10kg batches of EAF dust. The dust is provided by a local steel mill, with whom we are collaborating.

Recovery of zinc and lead from zinc plant residue ScienceDirect

2004年11月1日Significant amounts of zinc and lead could be recovered from zinc plant residue (ZPR) by using a two-stage recovery process comprising (1) roasting of the ZPR–H 2 SO 4 mixture followed by a water leaching and (2)

Selective mechanocemical alkaline leaching of zinc from zinc plants

2015年3月27日A new route for selective recovery of zinc from hazardous zinc plant purification residue was proposed by alkaline leaching process. The thermodynamic analysis revealed that by controlling

Processing for extraction of valuable metals from

2010年1月1日condition for extraction of lead and zinc from lead bearing ZPR of NILZ plant. At zinc recovery stage by . diluted sulfuric acid solution, the corresponding recoveries were as 0.1% Pb, 19.7% Zn

Recovery of zinc and lead from zinc plant residue ScienceDirect

2004年11月1日Zinc and lead recovery from zinc plant residue (ZPR) has been investigated. The residue is discarded as a cake from a Waelz kiln processing zinc–lead carbonate ores. The zinc plant residue containing 11.3% Zn, 24.6% Pb, and 8.3% Fe was blended with H 2 SO 4 and subjected to a process comprising roasting, water leaching,

Zinc in plants PubMed

Zinc (Zn) is an essential component of thousands of proteins in plants, although it is toxic in excess. In this review, the dominant fluxes of Zn in the soil-root-shoot continuum are described, including Zn inputs to soils, the plant availability of soluble Zn(2+) at the root surface, and plant uptake and accumulation of Zn.

Oxidative damage of workers in secondary metal recovery plants

In Taiwan, secondary copper smelters and zinc recovery plants primarily utilize recovering metal from scrap and dross, and handles mostly fly ash and slag with high temperature to produce ZnO from the iron and steel industry. The materials may contain organic impurities, such as plastic and organic

Lead Zinc Beneficiation Plant Layouts-HN Mining Machinery

Lead Zinc Beneficiation Plant Layouts Calcite Deep Processing Plant in Belgium Calcite deep processing production line in Belgium is composed of PE250 400 jaw crusher electrovibrating feeder HXM1021 micro powder mill hoister electrical cabinet packing machine and pulse dust collector. More Detail. Lead zinc beneficiation plant data of hzl

General Plant Layout and Equipment selection Principles

for sections on site layout with considerations to crime prevention through environmental design (CPTED) principles. c) Refer to the Health and Safety in Facility guidelines for arrangements between operational and break-out areas. d) Wastewater (resource recovery) plants and water treatment plants for drinking water may require

Sulfuric Acid Plant Metso Outotec

Maximize your operational efficiency, sustainability, and safety with Metso Outotec's sulfuric acid plant solutions. Our technology is based on more than 90 years of experience in a diverse range of projects we have delivered over 650 complete plants globally, with daily capacities ranging from 100 to 5,000 tons.

Locating and Estimating Sources of Nickel US EPA

13 Generalized flow diagram of a secondary zinc recovery plant .. 69 14 Generalized flow diagram of an electrolytic copper refinery .. 72 15 Representative process flow diagram of a ferrous metal production facility .. 75 16 Representative process flow diagram of a nonferrous metal,

Zinc Plant Expansion and Modification for Increased Metals Recovery

2020年1月25日Simplified flowsheet of the DL integration to Torreón zinc plant Full size image The calcine leaching consists of three stages: neutral leaching,acid leaching,and hot acid leaching . The lead –silver residue from hot acid leaching goes further to the lead smelter for recovery.

National Renewable Energy Laboratory (NREL) Home Page NREL

National Renewable Energy Laboratory (NREL) Home Page NREL

HoriZn Technologies HoriZnTech EAF Dust Recycling Israel

HoriZnTech’s laboratory and pilot plant are situated in Acker, Israel. Our zinc recovery process now routinely produces high purity metallic zinc powder from 10kg batches of EAF dust. The dust is provided by a local steel mill, with whom we are collaborating.

Pb Recycling Through Leaching, Precipitation, and Cementation from Zinc

2021年2月23日Abstract This stone presents the hydrometallurgical methods used for the recovery of concentrate and metallic lead from zinc plant residue (ZPR). The ZPR mainly consisting of 9.5% Pb and 7.5% Zn was initially leached by sulfuric acid under the following conditions: leaching temperature 90 °C, leaching time 90 min., sulfuric acid concentration

Zinc toxicity in plants: a review PubMed

2021年5月27日Zinc (Zn) is a natural component of soil in terrestrial environments and is a vital element for plant growth, as it performs imperative functions in numerous metabolic pathways. However, potentially noxious levels of Zn in soils can result in various alterations in plants like reduced growth, photosynthetic and respiratory rate, imbalanced

sbmchina/sbm lead zinc beneficiation plant layouts ppt.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Processing for extraction of valuable metals from

2010年1月1日The number of stages required for the extraction, stripping processes of zinc, cobalt and manganese was also evaluated. Three stagesscrubbing is requirement to eliminate cobalt from 0.05 g/L to...

Recovery of zinc and lead from zinc plant residue ScienceDirect

2004年11月1日Significant amounts of zinc and lead could be recovered from zinc plant residue (ZPR) by using a two-stage recovery process comprising (1) roasting of the ZPR–H 2 SO 4 mixture followed by a water leaching and (2)

Layout of a LCO₂ plant Linde Engineering

Plant components. Plant components. Cryogenic tanks. Coldboxes, packaged units and cryogenic columns. Plate-fin heat exchangers (PFHEs) Coil-wound heat exchangers (CWHEs) Water bath vaporizers. Helium solutions. Powering sustainable mobility for generations to come.

Zinc in plants PubMed

Zinc (Zn) is an essential component of thousands of proteins in plants, although it is toxic in excess. In this review, the dominant fluxes of Zn in the soil-root-shoot continuum are described, including Zn inputs to soils, the plant availability of soluble Zn(2+) at the root surface, and plant uptake and accumulation of Zn.

Pb Recycling Through Leaching, Precipitation, and Cementation from Zinc

2021年2月23日The zinc recovery obtained was 92.8%, which was finally directed to solvent extraction circuit to produce zinc cathode. Then acidic residue was subjected to alkaline leaching, using sodium...

Lead Zinc Beneficiation Plant Layouts-HN Mining Machinery

Lead Zinc Beneficiation Plant Layouts Calcite Deep Processing Plant in Belgium Calcite deep processing production line in Belgium is composed of PE250 400 jaw crusher electrovibrating feeder HXM1021 micro powder mill hoister electrical cabinet packing machine and pulse dust collector. More Detail. Lead zinc beneficiation plant data of hzl

Kinetic investigations of two processes for zinc recovery from zinc

The maximum zinc recovery, obtained during pyrometallurgical treatment was 72% at 1300°C after 60 min. Kinetic investigations revealed that the zinc oxide reduction is carried out in the transient kinetic area, where both diffusion and the chemical reaction control the overall process rate, with an activation energy of 38±5 kJ mol −1.

Sulfuric Acid Plant Metso Outotec

Maximize your operational efficiency, sustainability, and safety with Metso Outotec's sulfuric acid plant solutions. Our technology is based on more than 90 years of experience in a diverse range of projects we have delivered over 650 complete plants globally, with daily capacities ranging from 100 to 5,000 tons.

- 焦作市拉水渣

- Price Hold Set Quarry Stone Equipment Quarry Drilling Rock Machines

- 马传义安徽宿州

- 红砂岩批发价格

- Impact Crusher Blow Bars For

- 铁屑粉碎机多少钱

- 钙粉厂投资需要多少钱

- Oem Available Fl Series Spiral Classifier With Price Competitive

- Aggregates Crusher Crusher Fines Albuquerque Aggregate Organic Material

- 鄂式破碎机构造

- 四川巴中石膏线条

- 实验室用小型颚式破碎机报价

- 磨机型号台产

- Problem Of Mining Mill Plant In India A Report

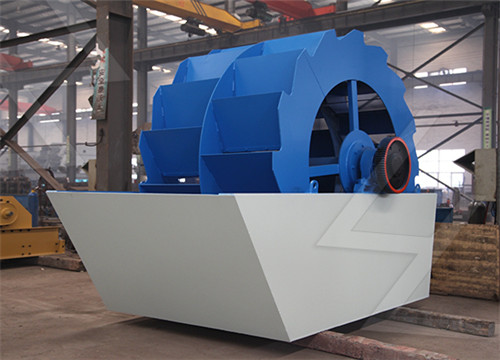

- 清砂设备5T