Dry High Recovery Rate Strong Magnetic Field Intensity Magnetic Separator

Variables and Applications on Dry Magnetic Separator

center magnetic field strength and the phase of high rotor speed, low silica content was observed in the case of the magnetic product, and found a positive correlation between

Separation analysis of dry high intensity induced roll

2014年9月1日A dry induced roll magnetic separator is simple and efficient for upgrading the magnetic mineral and materials. Weak paramagnetic minerals can be effectively

Prediction of Separation Performance of Dry High

2015年3月3日High intensity dry magnetic separators are gaining popularity for the separation of para-magnetic minerals due to the cost economic factor. Induced roll

Dry High Intensity Magnetic Separators (DHIMS) Eriez

Features: Magnetic field in excess of 21,000 gauss at the pole of the magnetic circuit. Standard 5 and 10 mils thick Kevlar belts. Optional FDA belting available. No power

Dry High-Intensity Magnetic Separation In Mineral Industry—A

2017年4月27日High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the

High Intensity Magnetic Separation Fundamentals

2018年2月15日High Intensity Magnetic Separators are designed for either wet or dry applications. Dry separators typically consist of a magnetized rotor in which the magnetic force is opposed by centrifugal

Dry high intensity magnetic separators LSV SOLLAU

Dry high intensity magnetic separators LSV SOLLAU s.r.o. Magnetic separation Mobile laboratory-sized version Separation of weakly magnetic particles Automatic cleaning without the interruption of the material flow

High Intensity Dry Roll Magnetic Separator

High Intensity Dry Roll Magnetic Separator DHIMS US$ 10,000 $ 8,000 Category: Magnetic Separators Description Description Roll-Type Magnetic Separators The rare-earth roll, generating magnetic field

Dry High Intensity Magnetic Separator JXSC Mineral

Dry High Intensity Magnetic Separator Capacity: 0.2-9 T/H Scope of Application: Removal of miscellaneous stones, improve the grade, achieve sales. The magnetic separation

Magnetic Separation SpringerLink

2022年2月28日Dry high-intensity magnetic separators can be used to separate paramagnetic The electromagnet causes inducing a magnetic field that generates areas of the strong magnetic field gradient. The processing of beach sand from Sri Lanka for the recovery of titanium using magnetic separation. Phys. Sep. Sci. Eng. 12, 13–22

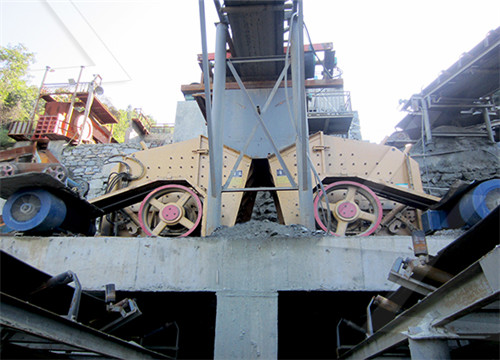

Separation characteristics of dry high-intensity drum magnetic separator

2022年11月1日Dry high-intensity drum magnetic separator (DHIDMS) has been effectively used for the utilization of low-grade iron ores, thus an in-depth investigation on the separation characteristics of the DHIDMS separator would contribute to its design and practical operation.

Separation analysis of dry high intensity induced roll magnetic

2014年9月1日A dry induced roll magnetic separator is simple and efficient for upgrading the magnetic mineral and materials. Weak paramagnetic minerals can be effectively removed from an ore by maintaining the field intensity up to ~ 2.5 T,.IRMS as shown in the Fig. 1 consists of a horse-shoe magnet faced by an iron bridge bar and of two rolls,

Prediction of Separation Performance of Dry High Intensity Magnetic

2015年3月3日High intensity dry magnetic separators are gaining popularity for the separation of para-magnetic minerals due to the cost economic factor. Induced roll magnetic separator is found to be an effective dry separator for the separation of fine particles. Separation efficiency of this separator depends on mineral characteristics and

Separation characteristics of dry high-intensity drum magnetic separator

2022年11月1日ABSTRACT High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating Expand 43 Influence of particle size on dry high-intensity magnetic separation of paramagnetic mineral S. K. Tripathy, N. Suresh

Dry High-Intensity Magnetic Separation In Mineral Industry—A Review

2017年4月27日High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating different minerals has become an active research topic. Several attempts have been made by different researchers and technologists to

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日High Intensity Magnetic Separator The strong magnetic separator is an upgraded product of the dry iron remover developed based on the original dry iron remover by improving the magnetic field strength and the arrangement of the magnetic blocks.

High Intensity Dry Roll Magnetic Separator

The roll separator is capable of processing 100 kg/hr/cm of roll width of 20 by 200 mesh material resulting in capacities up to 10 TPH on a 1.5-meter wide separator. Typically iron levels are reduced to 0.02 to 0.05 percent.

Dry High Intensity Magnetic Separator JXSC Mineral

Its magnetic system is all made of high-performance rare-earth nd-fe-b material and high-quality ferrite material with high magnetic field strength (up to 12000 GAUSS). The high-intensity magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite with particle size less than 3mm, and also for

Dry High-Intensity Magnetic Separation In Mineral

2017年4月27日Dry processing becomes the most sustainable approach, in particular whenever thermal drying can be avoided. Dry high-intensity magnetic separation is particularly attractive in this case, given...

Effect of magnetic field orientation on high gradient magnetic

The magnetic field orientation has a significant effect on HGMS performance. The VMF achieves a small magnetic leakage factor and a high magnetic induction. The VMF achieves a high recovery for fine magnetic particles. A properly designed magnet greatly improves the HGMS performance.

MMPB-730N Rare Earth Roll Microsoft

and generate a high-intensity high-gradient magnetic field. A contour plot of the magnetic field configuration of this magnetic circuit is illustrated in Figure 2. The highest magnetic field strength occurs at the interface between the magnetic disc and the steel pole piece. A close-up of the magnetic field configuration at this interface is also

For dry and wet processing Low Intensity Magnetic

into three classes of magnetic intensity i.e., low, medium, and high, all depending on the characteristics of the minerals subjected to magnetic processing: • Strong magnetic minerals (ferromagnetic) can be processed by Low Intensity Magnetic Separators (LIMS). • Medium magnetic minerals (generally defined as high

Influence of process parameters of dry high intensity magnetic

2017年1月13日Tripathy et al. (2017b) used a rare earth roll magnetic separator (RERMS) and a dry induced-roll high-intensity magnetic separator (IRMS) to separate hematite from low-grade iron ore fines. From

Magnetic Separation SpringerLink

2022年2月28日A dry high-intensity magnetic separator is a waterless separation machine introduced to separate weakly magnetic particles that DLIMS cannot process. This technology employs a greater magnetic field strength provided by an induced or permanent magnet to separate the materials based on their magnetic susceptibility [20,

Eriez Dry High Intensity Magnetic Separation

Engineered for optimum performance. High-intensity magnetic roll assembled from rare earth permanent magnets. Magnetic roll diameters of 4, 6, and 12 inches. Magnetic roll widths up to 60 inches. Continuous

Separation characteristics of dry high-intensity drum magnetic separator

2022年11月1日For a dry high-intensity drum magnetic separator (DHIDMS), its magnet system was generally designed into an extruding magnetic structure, to improve the magnetic field intensity and gradient on the drum surface; and in this way, it is applicable for the separation of weakly magnetic ores and for the purification of non-metallic ores,

Separation analysis of dry high intensity induced roll magnetic

2014年9月1日A dry induced roll magnetic separator is simple and efficient for upgrading the magnetic mineral and materials. Weak paramagnetic minerals can be effectively removed from an ore by maintaining the field intensity up to ~ 2.5 T,.IRMS as shown in the Fig. 1 consists of a horse-shoe magnet faced by an iron bridge bar and of two rolls,

Prediction of Separation Performance of Dry High Intensity Magnetic

2015年3月3日High intensity dry magnetic separators are gaining popularity for the separation of para-magnetic minerals due to the cost economic factor. Induced roll magnetic separator is found to be an effective dry separator for the separation of fine particles. Separation efficiency of this separator depends on mineral characteristics and

Separation characteristics of dry high-intensity drum magnetic separator

2022年11月1日DOI: 10.1016/j.mineng.2022.107861 Corpus ID: ; Separation characteristics of dry high-intensity drum magnetic separator @article{Yi2022SeparationCO, title={Separation characteristics of dry high-intensity drum magnetic separator}, author={Fan Yi and Luzheng Chen and Jianwu Zeng and Yaxiong

Dry High-Intensity Magnetic Separation In Mineral Industry—A Review

2017年4月27日High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating different minerals has become an active research topic. Several attempts have been made by different researchers and technologists to

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日The dry-type three-disk strong magnetic separator is suitable for separating various magnetic mineral mixed ores. According to the magnetic difference of minerals, the magnetic field of different strengths can be formed by adjusting the excitation current of the disks at all levels to separate the minerals. with high magnetic field

Dry High Intensity Magnetic Separator JXSC Mineral

Its magnetic system is all made of high-performance rare-earth nd-fe-b material and high-quality ferrite material with high magnetic field strength (up to 12000 GAUSS). The high-intensity magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite with particle size less than 3mm, and also for

High Intensity Dry Roll Magnetic Separator

The roll separator is capable of processing 100 kg/hr/cm of roll width of 20 by 200 mesh material resulting in capacities up to 10 TPH on a 1.5-meter wide separator. Typically iron levels are reduced to 0.02 to 0.05 percent.

Magnetic Separators Eriez

Flocculators. Compact, powerful units use magnets to speed settling of magnetic solids from slurries and liquids for easier recovery and separation. Used widely in the iron and coal mining industries to speed settling of fine magnetic particles in ore slurries and heavy media slurries, they are finding new use in steel and other industries for

MMPB-730N Rare Earth Roll Microsoft

and generate a high-intensity high-gradient magnetic field. A contour plot of the magnetic field configuration of this magnetic circuit is illustrated in Figure 2. The highest magnetic field strength occurs at the interface between the magnetic disc and the steel pole piece. A close-up of the magnetic field configuration at this interface is also

For dry and wet processing Low Intensity Magnetic

into three classes of magnetic intensity i.e., low, medium, and high, all depending on the characteristics of the minerals subjected to magnetic processing: • Strong magnetic minerals (ferromagnetic) can be processed by Low Intensity Magnetic Separators (LIMS). • Medium magnetic minerals (generally defined as high

Evaluation of Chromite Recovery from Shaking Table Tailings by Magnetic

This study aimed to evaluate the chromite recovery from shaking table tailings of Forumad plant by a dry high-intensity magnetic separation. The average feed grade of chromium trioxide (Cr 2 O 3) was 7.62% by XRF. Also, different mineral phases were determined by XRD, identifying the presence of Chrysotile, Augite, Albite, Chlorite and Chromite