List Types Of Crusher Screening Plant

CrushingScreening Plants MEKA

MEKA Crushing and Screening Technology serves all industries involved in reduction of rock and minerals, meeting your specific requirements from single crushers to mobile crushing plants and complete rock

Crushing and Screening Agg-Net

根据热度为您推荐•反馈

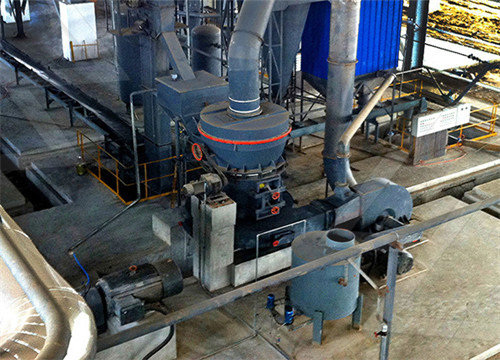

Screening/Sizing McLanahan

Screening/Sizing. Sizing is the general separation of products according to their size. The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to

Screens MEKA CrushingScreening Plants

Inclined Screen. MEKA inclined screens provide screening efficiency that is high quality and dependable. Our screens come in various sizes starting from 2 m² (22 sqft) up to 16 m² (172 sqft) and are equipped with up to

Crusher, Crushing plant All industrial manufacturers

Fabo Crushing ScreeningConcrete Plants (72) FAM (5) Fast Verdini Srl (1) Fives (2) Dorr-Oliver Eimco (5) MAAG Gear AG (1) FORREC (1) Franklin

Tips for designing an efficient crushing and screening

2013年4月4日There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

10 Types of Stone Crusher Plants Price and More for Sale

Stone crusher plant machine: Silo, GZD850x3000 vibrating feeder, PE500×750 jaw crusher, B650×20 m belt conveyor, PF1010 impact crusher, B650x25 m belt conveyor,

Types of Crushers Mineral ProcessingMetallurgy

2015年6月23日1 fixed cheek with the rotation axis; 2 a movable cheek; 3, 4 the eccentric shaft; 5 rod; 6 hinged rear bearing spacer cheeks; 7 spring; 8, 9 width adjustment mechanism of

Types of Rock Crushers Quarry Crushing Equipment

The number of crusher types in terms of style and configuration can be more challenging to quantify, as there are lots of ways to customize rock crushers. However, you’ll find four basic designs—cone, jaw, gyratory,

Rock Crushers, Stone Crushers, Screening and

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. Stationary jaw crushers jaw crushers are of the single-toggle type with advanced

Mechanical screening Wikipedia

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size.. This practice occurs in a variety of industries such as

Screening/Sizing McLanahan

Popular screening media includes woven wire cloth, urethane, rubber or a combination of urethane and wire cloth or urethane and rubber. Each type of screen media offers producers different options when it comes to

Wobbler Feeders MEKA CrushingScreening

Exclusively designed non clogging and self cleaning triangular bars, it is a sturdy machine suitable for heavy duty work. Recommended for pre-screening and cleaning of dirty material with a high content of clay and

Rock Crushing Equipment Rock Crushers Kemper

If you are a rock, sand, gravel, or mineral processing industry veteran, you know that several different types and styles of crushing equipment are used at crushing and screening plants. An individual crusher's

Coal McLanahan

Cone Crushers DDC-Sizers Feeder-Breakers Hammermill Crushers Impact Crushers Primary Impact Crushers Secondary Roll Crushers Rotary Breakers Sampling/Pilot Plant Crushers Screening/Sizing

Topsoil, Compost, AggregateRecycling Screens

Grizzly Screen. This is a heavy duty screen used on the top deck of our Scalper 107T, Scalper 107D and 612T / 612W Trommels for rough screening applications. For crushing applications the grizzly screen

Crushing in Mineral Processing

2015年12月26日Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP.

Safe Use of Mobile CrushersScreening Plant Issuu

2017年4月11日NFDC Safe Use of Mobile Crushers & Screening Plant. DRG 110:2014. INTRODUCTION The National Federation of Demolition Contractors (NFDC) is represented on the British Standards

Mobile crusher, Mobile crushing and screening

impact crushing plant General 03. mobile primary. Capacity: 250 t/h 350 t/h. Weight: 86,000 kg. PRODUCT AVAILABLE IN STOCK General Makina, one of the mobile crusher manufacturer leaders, has superior

Mobile Crusher Plant For Mobile Crushing And Screening

The classification of mobile crushing plant 1. Mobile crusher plant is mainly divided into two categories, tire type, and crawler type, according to the walking mode. Tire type mobile cone crushing plant Crawler type mobile crusher plant 2.

Fabo Company Mobile Crusher Plants Mobile Crusher And

FABO manufactures and installs mobile and Stationary type Stone Crushing and Screening Plants according to customer requirements. Crushing and Screening Plants can be used in many sectors such as recycling, quarries and ore. Also it can be used in mineral beneficiation facilities and urban transformation.

The Top Rock Crusher Brands Mellott

2020年5月20日As they put it on their website, Metso’s selection “covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers optimized for any size reduction need.” Whether you need a primary rock crusher or a mobile plant, a Metso machine is a solid option to consider. Superior

Mechanical screening Wikipedia

Screening falls under two general categories: dry screening, and wet screening. From these categories, screening separates a flow of material into grades, these grades are then either further processed to an

Rock CrushingScreening Equipment Eagle Crusher

Eagle Crusher offers a full line of heavy-duty crushing and screening plants and systems designed for processing concrete, asphalt, and aggregate with ease. 1.800.25.Eagle (253.2453) DEALER LOCATOR; Blog; Explore what’s new in our lineup of heavy-duty crush-ing and screening plants and systems. NEWS. Raptor Cone Crusher Line.

Screening/Sizing McLanahan

Popular screening media includes woven wire cloth, urethane, rubber or a combination of urethane and wire cloth or urethane and rubber. Each type of screen media offers producers different options when it comes to

Wobbler Feeders MEKA CrushingScreening

Exclusively designed non clogging and self cleaning triangular bars, it is a sturdy machine suitable for heavy duty work. Recommended for pre-screening and cleaning of dirty material with a high content of clay and

Portable CrushingScreening Plants For Concrete,

Scalper 107T Portable Screening Plant. The Scalper 107T is a patented, extremely heavy-duty, track-mounted screening plant designed to screen heavy rock, sand, soils and more. It works best with your 3 to 5 yard

Rock Crushing Equipment Rock Crushers Kemper

If you are a rock, sand, gravel, or mineral processing industry veteran, you know that several different types and styles of crushing equipment are used at crushing and screening plants. An individual crusher's

Jaw crusher UMK series Uğurmak Crushing and

Find out all of the information about the Uğurmak Crushing and Screening Plants product: jaw crusher UMK series. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point

Crushing in Mineral Processing

2015年12月26日Impact crushers are commonly used to crush rocks with a silica contain under 5% such as coal, limestone, and phosphate. The only reason why you would use an impact mill/crusher or a hammer mill on a

Topsoil, Compost, AggregateRecycling Screens

Grizzly Screen. This is a heavy duty screen used on the top deck of our Scalper 107T, Scalper 107D and 612T / 612W Trommels for rough screening applications. For crushing applications the grizzly screen

Safe Use of Mobile CrushersScreening Plant Issuu

2017年4月11日NFDC Safe Use of Mobile Crushers & Screening Plant. DRG 110:2014. INTRODUCTION The National Federation of Demolition Contractors (NFDC) is represented on the British Standards

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP.

Mobile crusher, Mobile crushing and screening plant All

impact crushing plant General 03. mobile primary. Capacity: 250 t/h 350 t/h. Weight: 86,000 kg. PRODUCT AVAILABLE IN STOCK General Makina, one of the mobile crusher manufacturer leaders, has superior stone crushing and screening capabilities at maximum mobility. Combining many conveniences

Fabo Company Mobile Crusher Plants Mobile Crusher And

The crusher machines that generate large stones, rocks, ore etc. into small pieces are generally called Crushing and Screening Plant. In particular, the rough materials obtained in stone quarries can be crushed to small sizes and used in

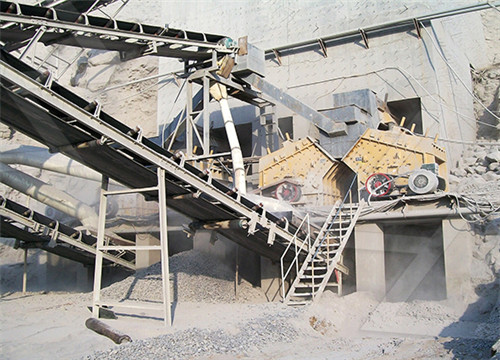

Crushing plant Wikipedia

A Crushing plant is one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary,) where different crushing, selection and transport cycles are done