Impact Mining Mill Wear Parts Costs

Mine operating costs and the potential impacts of energy

2014年2月1日 Highlights. •. Mine and Mill costs for a giving mining operation are approximately equal. •. Mining techniques influence the distribution of mine operating costs. •. Savings in milling costs will significantly affect total mine operating cost. •. Coarse

Mill liners Metso Outotec

Mining Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process. A mill lining is a customized wear part.

进一步探索

Mill Liners MultotecAll Metso Corporation catalogs and technical brochures Dir根据热度为您推荐•反馈

Mill Hammer Parts Impactor Wear Parts PRODUCTS

Ball MillSag Mill Parts. Mill Liner. Roller Tire Raymond. Roller Tire Willams. Steel Ball. IMPACTOR WEAR PARTS Impact Blow bar We have various kinds of material solutions

Mining Replacement Wear Parts Crushers, Sizers,

Our mining industry products include parts for gyratory, jaw, roll and cone crushers, feeders, SAGball mills, mining valves, roll crushers, sizers, and grizzlies. We have a rotating

A Definitive Guide To Mining Wear Parts Cast Steel

2021年6月7日 Mining wear parts and excavating wear parts are commonly replaced components used in mineral and aggregate extraction and processing. Heavy equipment

Wear parts Archives International Mining

2023年2月7日 The scans are used to understand the way the mill liners wear, to optimise the liner design, and to accurately predict the reline schedules. Weir said in 2020 it

MineMill Equipment Cost Guide 2021 Digital CostMine

Now estimators have available a convenient source of hourly operating costs as well as capital costs for virtually every piece of equipment listed in our previous guides. Included

Equipment Cost Calculator Costmine

The industry's most comprehensive online tool for minemill cost estimating. The Equipment Cost Calculator provides all the same information as our MineMill

Mining mill liners with different material for mining industry

2021年1月23日 Its hardness is HRC = 49 and its impact toughness is outstanding. Its wear resistance is about 2 times that of high carbon cast iron liner, which is suitable for

Hammer Mill Wear Plates Manufacture and Hammer Mill

Hammer Mill Wear Plates. manufacturer, factory, supplier from China. (Total 24 Products for Hammer Mill Wear Plates) Customized Hammer Head Of Mining Crusher Hot Sale.

Qiming Casting-China’s wear-resistant casting industry

Qiming Casting is able to produce and deliver suitable quality crusher replacements and worn parts at extremely low costs for all major mobile crushing and screening equipment thanks to the hiring of highly experienced people. Our success in the quarry and mining industries has been attributed to our emphasis on excellent craftsmanship, cost

Crusher Wear Parts Wear Parts For Industry Qiming

As a steel foundry in China, Qiming Casting focuses on supply high-quality crusher wear parts for customers. Our premium manganese steel and alloy steel crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance of the equivalent original equipment manufacturers’ castings. On the

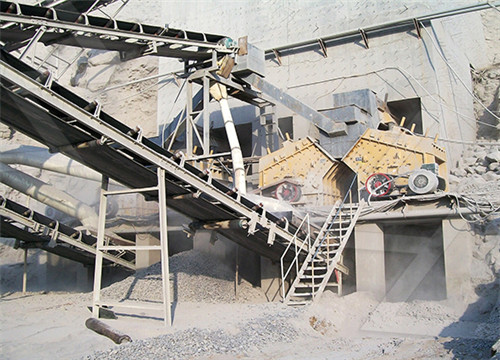

CSP Impact Crusher wear parts Cast Steel Products

CSP Impact Crusher wear parts are designed to meet the needs of our aggregates and mining customers and deliver cost efficiency, reduced downtime, and longer service life. Our CSP Impact Crusher wear parts are available for both horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers.

A Definitive Guide To Mining Wear Parts Cast Steel

2021年6月7日 Mining wear parts and excavating wear parts are commonly replaced components used in mineral and aggregate extraction and processing. Heavy equipment wear parts include buckets, shovels, teeth, dragline parts, grinding mill liners, crawler shoes, links, clevises, power shovels, and wear plates. Wear parts or wear liners for draglines,

Wear parts Archives International Mining

2023年2月7日 The scans are used to understand the way the mill liners wear, to optimise the liner design, and to accurately predict the reline schedules. Weir said in 2020 it installed the first pilot Terraflowing® plant at a customer’s mine site designed to cost-effectively reduce water in tailings, enabling this waste product to be safely stored or

Wear parts network, find your supplier and experts of wear

We provide wear parts and wear solutions that keep industries up and running with optimized productivity and service life. Find a supplier. We cover wear challenges in all industries. Search for the wear parts you need by industry or equipment. Search for wear parts. WearCalc.

Equipment Cost Calculator Costmine

The industry's most comprehensive online tool for minemill cost estimating. The Equipment Cost Calculator provides all the same information as our MineMill Equipment Cost Guide in a convenient online format. Build your equipment fleet, tabulate its costs, adjust for local economics and conditions, and export the data into your own

Part List bdiwearparts

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, and Ball mill liners and Forged steel balls. We supply wear parts to the USA, Canada, Europe, Australia and Africa. BDI aims to help customers reduce costs, increase parts availability, minimize

(PDF) Preventive Maintenance of Mining

2014年1月1日 As past experiences showed, the unplanned and sudden transformation of mining areas has a negative impact on the economy [5,8] and environmental sustainability [9][10][11] [12] [13][14]. One of

AusIMM Leading the way for people in resources

2021年6月24日 AusIMM Leading the way for people in resources

A discussion on the measurement of grinding media wear

2016年7月1日 1. Introduction. The mining industry strongly depends on the comminution operations to promote mineral liberation. This stage is characterized by considerable consumption of power, as approximately only 10% of the power consumed is effectively spent in particles breakage .. Although there is some divergence regarding cost

The Largest Crusher Wear Parts Manufacturer In China

MGS Casting premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve, and we are one of the largest crusher wear parts supplier in China. MGS Casting premium manganese steel that has been developed from the original Hadfield’s manganese steel specification, our variation can

Wear parts Archives International Mining

2023年2月7日 The scans are used to understand the way the mill liners wear, to optimise the liner design, and to accurately predict the reline schedules. Weir said in 2020 it installed the first pilot Terraflowing® plant at a customer’s mine site designed to cost-effectively reduce water in tailings, enabling this waste product to be safely stored or

Wear parts network, find your supplier and experts of wear

We provide wear parts and wear solutions that keep industries up and running with optimized productivity and service life. Find a supplier. We cover wear challenges in all industries. Search for the wear parts you need by industry or equipment. Search for wear parts. WearCalc.

Minding the Grind: Maintenance Options to

2023年2月14日 Component wear, regardless of whether it involves bearings, lifters or other parts of the machine, is a constant concern for SAG mill operators. Industry suppliers have developed a wide variety of liner

Part List bdiwearparts

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, and Ball mill liners and Forged steel balls. We supply wear parts to the USA, Canada, Europe, Australia and Africa. BDI aims to help customers reduce costs, increase parts availability, minimize

AusIMM Leading the way for people in resources

2021年6月24日 AusIMM Leading the way for people in resources

Key considerations when selecting a mill lining system Weir

Figure 2: Cascading-impact action in a SAG mill. Rubber and composite mill lining systems. In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost.

Blasting costs MiningMonthly

2016年9月14日 Even though drill and blast costs in the ore have increased, the overall net benefit to Mt Rawdon, including mining and processing costs, is expected to be more than $5 million. While the Vistis system is a key input to the mine to mill program the benefits Mt Rawdon achieved are equally attributable to the operational changes it made.

(PDF) Mining Spare Parts Gary Li Academia.edu

Download Free PDF. Mining Spare Parts dajia-engineering Girth Gear, Support roller, jaw plate, kiln tyre, pinion gear, ball mill assembly, kiln shell, mill gear, etc. fCompany Instruction Henan No.3 Machinery Factory is one of largest machinery manufacturing and important enterprises in Zhengzhou City, founded in 1902.