Condition Monitoring Vibratory Screens

Development of a Cyber-Physical System to Monitor Early

2021年10月5日 Vibratory screens are used in mining to classify mineral and send it to different pathways, normally using conveyor belts. Vibration analysis techniques are

Condition Monitoring of Horizontal Sieving Screens—A

2023年2月12日 Predictive maintenance is increasingly popular in many branches, as well as in the mining industry; however, there is a lack of spectacular examples of its practice

Industrial investigation of vibrating screens failure

Vibratory screens are used in mining to classify mineral and send it to different pathways, normally using conveyor belts. Vibration analysis techniques are commonly used for

(PDF) Condition monitoring of systems in

2017年12月17日 The present work is a case study of various online and offline CM techniques in practice at 2 x 250 MW Adani Dahanu Thermal

Sensors for Monitoring Vibratory Screens and Feeders

PCB ® manufactures sensors used by design engineers and predictive maintenance professionals to test and measure vibration, pressure, force, acoustics, load, and shock

Condition Monitoring for Aggregate Screens Agg-Net

2023年3月8日 Condition monitoring can be used to establish a wide range of equipment parameters, to provide an early warning that conditions have changed. Don Valley

mill/sbm condition monitoring of vibrating screens.md at

Contribute to crush2022/mill development by creating an account on GitHub.

how to condition monitor vibrating screens

Condition Monitoring Of Vibrating Screens. Vibrating Screen Condition Monitoring Jul 29, 2021 Haver Boecker Niagara have launched a new addition to their Pulse portfolio with

condition monitoring vibratory screens,

condition monitoring vibratory screens; types of vibratting screens; how does vibratingscreen work; ore hopper with grizzly feeder; crusher and screen hire in Screening minerals for

Flip-Flow Screen Action Vibratory Conveyors

1 The VIBRA-SNAP ® Flip-Flow Screen is an effective alternative to conventional rigid deck screeners for the efficient processing of your difficult materials. It is ideally suited for

Enhance your maintenance with vibration monitoring and

2023年3月7日 Vibration measurement is the practice of measuring vibration levels with handheld tools, sensors, or on-line systems, often to detect or diagnose faults in vibrating machinery. Measuring vibration gives you insight into the condition of your components, from shafts to fan blades and bearings. Vibration measurements can be general “overall

Development and Verification of the Diagnostic Model of

2020年6月18日 Some of those systems have the specialised functions for diagnostics, namely, of the sieving screens. (i) CONIQ (Schenck) is a condition monitoring system, which can detect possible defects in the screen based on a six-dimensional vibration measurement using piezoelectric accelerometers and bearings temperature .

Condition Monitoring an overview ScienceDirect Topics

The concept of condition monitoring (CM) is an evolution of diagnostic and prognostic systems. The goal of CM of mining machinery is to examine its functional health. Real-time assessment of its functional health is useful for predicting fault in components/operation and thereby improving performance of equipment.

What is Condition Monitoring? (Everything You Need to

Contact Us. Condition monitoring (CM) is the process of monitoring a particular condition in machinery (such as vibration, temperature, etc) to identify changes that could indicate a developing fault. It is a major part of predictive maintenance as implementing condition monitoring allows for maintenance to be scheduled and preventive actions

Schaeffler Showcases Innovations for the Construction and

2 之 Solutions for Vibratory Applications Vibratory screens used for separating solid materials according to grain size are subjected to some of the most severe stresses in the construction and

Condition Monitoring for Aggregate Screens Agg-Net

2023年3月8日 Condition monitoring can be used to establish a wide range of equipment parameters, to provide an early warning that conditions have changed. Don Valley Engineering can provide and install condition monitoring for their own range of screens, feeders and centrifuges, as well as for third-party screening machines and material

The Role of Vibration Monitoring Schaeffler Group

2019年5月24日 The Role of Vibration Monitoring Schaeffler Group

en/vibration monitoring on vibrating screens.md at main

Contribute to lbsid/en development by creating an account on GitHub.

Machine-Condition Monitoring using Vibration bksv

2016年6月8日 Due to the large number of monitor ing points on a stone machine, it is very important that the condition monitoring is carried out systematical ly. On the 3 stone machines in Alma the maintenance staff measure ap proximately 2900 monitoring points 1100 on machine no.14, and 900 each on machines 9 and 10. To be able to

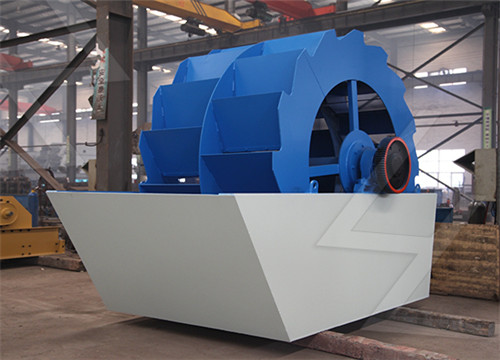

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

Failure and sensitivity analysis of a reconfigurable

2017年10月1日 To address this, Zhi-shan and Bao-liang, highlighted that despite the development of Large Vibrating Screens, continuous deployment of fault detections, condition monitoring and other preventive maintenance strategies are fundamental to guarantee its safety, reliability and serviceability during operation. The safer approach to

Mechanical Vibrations and Condition Monitoring

Description. Mechanical Vibrations and Condition Monitoring presents a collection of data and insights on the study of mechanical vibrations for the predictive maintenance of machinery. Seven chapters cover the foundations of mechanical vibrations, spectrum analysis, instruments, causes and effects of vibration, alignment and balancing methods

(PDF) A Review on Vibration-Based Condition Monitoring

2022年1月18日 Monitoring vibrations in rotating machinery allows effective diagnostics, as abnormal functioning states are related to specific patterns that can be extracted from vibration signals. Extensively

CONiQ Condition Monitoring for Vibrating Screens

CONiQ ® is suitable for all Schenck Process linear vibrating equipment and other vibrating machines. It requires minimal cabling, making it more robust than other condition monitoring systems an essential requirement for heavy load bearing vibrating machines, while providing greater flexibility, stability and reliability than wireless-only

What is Vibration Analysis and What is it Used

Vibration analysis is predominantly applied for the condition monitoring on machineries and their key rotating parts, including but not limited to: Bearings, gears, shafts, free wheels. Rotating machines such as

Types of Vibration Sensors for Condition Monitoring

2021年11月4日 Accelerometer Vibration Sensors. Accelerometer vibration sensors are another extremely common type of vibration sensor. An accelerometer measures the acceleration forces acting on an object. Static forces, such as gravity, are constantly acting on objects. Dynamic forces, such as vibration, are those applied to objects at varying rates.

Vibratory Condition Monitoring of Machines (豆瓣)

内容简介 . Vibratory Condition Monitoring of Machines discusses the basic principles applicable in understanding the vibratory phenomena of rotating and reciprocating machines. It also addresses the defects that influence vibratory phenomenon, instruments and analysis procedures for maintenance, vibration related standards

Machine-Condition Monitoring using Vibration bksv

2016年6月8日 Due to the large number of monitor ing points on a stone machine, it is very important that the condition monitoring is carried out systematical ly. On the 3 stone machines in Alma the maintenance staff measure ap proximately 2900 monitoring points 1100 on machine no.14, and 900 each on machines 9 and 10. To be able to

The Role of Vibration Monitoring Schaeffler Group

2019年5月24日 The Role of Vibration Monitoring Schaeffler Group

how to condition monitor vibrating screens

Condition Monitoring Of Vibrating Screens. Vibrating Screen Condition Monitoring Jul 29, 2021 Haver Boecker Niagara have launched a new addition to their Pulse portfolio with the introduction of Pulse Condition Monitoring (Pulse Basic concepts of vibrating screens: What they ,Also called simply screens, a vibrating screen is formed by a vibrant chassis that