Processing Equipment For Manganese Alloy

Manganese processing The metal and its alloys Britannica

More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron. Most manganese is consumed as high

进一步探索

The 7 Most Useful Manganese Ore Beneficiation MethodsThe Properties and Effects of Manganese as an Alloying EleManganese Mining and Processing: Everything you Need to Manganese Alloys an overview ScienceDirect TopicsManganese Ore Processing根据热度为您推荐•反馈

A Sustainable Process to Produce Manganese and Its

2021年12月24日 Hydrogen and aluminum were used to produce manganese, aluminum–manganese (AlMn) and ferromanganese (FeMn) alloys through experimental

Manganese Mining and Processing: Everything

2022年8月1日 The Manganese Mining Process. More than 25 million tons of manganese are mined every year. Most manganese mining occurs in

Manganese Alloys an overview ScienceDirect Topics

Aluminum alloys with a Mn content of 1% or more are widely used in beverage cans and in -handling equipment. Manganese bronzes are copper-based alloys, strengthened by

Hydrometallurgical Processing of Manganese Ores: A

2017年6月25日 1.2. Manganese Alloy The production of manganese alloy from manganese ore is an energy intensive process and therefore, apart from manganese

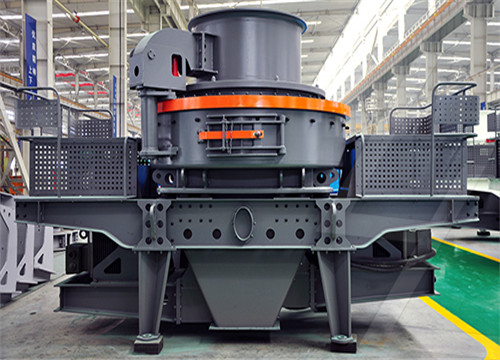

Manganese ore processing technology and

2019年7月2日 The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the coarse level and shaking at the fine level.

Manganese Ore Processing Mineral Processing

2016年4月27日 Concentration—Gravity Methods of treating Manganese Ore. The mill feed, drawn from one or more bins, is sampled at the ore feeder discharge to obtain a composite sample for mill control. After

github

processing equipment for manganese alloy. Processing Equipment For Manganese Alloy processing equipment for manganese alloy Grinding The Gulin product line,consisting

processing equipment for manganese alloy

processing equipment for manganese alloy May 01, 1991 @article{osti_, title = {Processing of manganese zinc ferrites for high frequency switch mode power supplies},

processing equipment for manganese alloy

2021年10月14日 Novel processing of iron–manganese alloy-based. 2013-11-1 The morphologies of the Fe and Mn precursor powders used in this study as well as the

Cradle-to-gate life cycle assessment of global manganese

2016年2月8日 Manganese plays a critical supporting role in a variety of applications: as an essential nutrient for processing fats, carbohydrates, and protein; as a component of batteries, chemicals, and fertilizers; and as an alloying element in steel, aluminum, and copper production (IMnI 2015).Approximately 90 % of total manganese production is in

Manganese processing Britannica

manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an

World-class, environmentally friendly

Eramet Norway has a century of experience in manufacturing manganese alloys. This knowledge base, developed over generations, is Eramet Norway’s most important resource and asset. This expertise has also

Manganese ore processing technology and

2019年7月2日 The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the coarse level and shaking at the fine level.

Manganese Ore Processing Mineral Processing

2016年4月27日 The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores

Manganese Recycling MetallurgistMineral Processing

2018年3月25日 Additional feed to processing was home scrap containing 8,354 st of manganese and prompt scrap containing 2,555 st of manganese. During processing, loss material containing 36,421 st of manganese and downgraded material containing 3,117 st of manganese were generated. and large pieces of many different types of machinery.

Detailed Project Report on ferro alloy (silicon manganese)

Project Report on ferro alloy (silicon manganese) Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Manufacturing Plant, Profile, Business Plan, Industry Trends, Market Research, Survey, Investment Opportunities, Cost And Revenue, Plant

Silico Manganese Production Entrepreneur India

Silico manganese is an alloy with 60% to 68% manganese, 14% to 21% silicon, and 5% to 2.5% carbon. It is produced by smelting of slag from high-carbon Ferro Manganese or of Manganese ore with coke and a quartz flux in a submerged electric arc furnace. The process requires power consumption of about 3,800 to 4,800 kilowatt-hours per tonne.

Preparation of PTFE particles-doped Manganese

2023年3月1日 In present , the growth process of the phosphate coating on 30CrMnMoTi alloy steel fabricated by a high temperature manganese phosphating was investigated.

High Purity Alloy Manufacturer Ferro Silicon Manganese

* Low carbon ferromanganese is not only suitable for low carbon alloy structural steel, especially for high quality steel, but also can optimize the alloy, improve the internal quality of steel, reduce the cost of steelmaking alloy without changing the original steelmaking process, with obvious economic benefits.

Review of Manganese Processing for Production of

2018年9月5日 The cost of producing the required manganese units, however, has received considerably less attention. The present work is Part 1 of a two-part review of Mn processing in the context of ultra high manganese alloys. This portion of the review addresses the properties and chemistry of TRIP and TWIP alloys, the

Manganese BeneficiationProcessing Technology in China

2022年5月27日 At present, the process flow of manganese oxide ore treatment in China is generally to crush the ore to 6 ~ 0mm or 10 ~ 0mm, and then group it, jigging for coarse grade and shaking tables for a fine grade. The equipment is mostly Hartz reciprocating jig and 6-s shaking table. jig separator. shaking table.

Materials Free Full-Text Superior Comprehensive

A low-carbon medium manganese steel (0.12C-3.13Mn) containing Cr, Ni, Mo, V, and Cu elements was designed to replace the AISI 4330 steel applied in the oil and gas industry. The mechanical properties, microstructures, and fatigue crack growth rate were comparatively analyzed using uniaxial tension tests, microstructure characterization, and

(PDF) Working towards an increase in

2018年6月1日 benefit of reactive high grade ore in manganese alloys manufacturing. Proceedings of INFACON XI,New Delhi, India, 18–21 February 2007. Indian Ferro-Alloy Producers Association. pp. 217–230.

High Carbon Ferro Manganese Manufacturing Plant,

So, the Ferro alloy industry is suffering gross under utilization of capacity, and may remain so in the short to medium term. India produced 1.08 million tons (million) of manganese alloys in 2006-07 according to the IFAPA. Around 2.5 million tons of manganese ore was required for producing this ore.

3 Beneficial Effects of Manganese in Steel Knowlton

2018年10月23日 Steel holds an abundant place in the modern world. You can find steel anywhere from automobiles to high-rise buildings and industrial processing equipment. Many different types of steel exist, each of them being a slightly different alloy with iron as its base metal. Manufacturers then add other elements to boost the overall performance of the

Preparation of PTFE particles-doped Manganese

2023年3月1日 In present , the growth process of the phosphate coating on 30CrMnMoTi alloy steel fabricated by a high temperature manganese phosphating was investigated.

Ferroalloys Manufacturing Plant, Detailed Project Report,

2016年5月18日 Ferro manganese along with Fe-Si, Fe-Cr, is a bulk ferro-alloy. Iron for Farm implements uses up to 1.75% Mn and also in automobile parts. Ship construction industry uses steels with even higher content; riffle barrels and heat treated forgings necessarily use ferro manganese as an alloying additive.

High Purity Alloy Manufacturer Ferro Silicon Manganese

* Low carbon ferromanganese is not only suitable for low carbon alloy structural steel, especially for high quality steel, but also can optimize the alloy, improve the internal quality of steel, reduce the cost of steelmaking alloy without changing the original steelmaking process, with obvious economic benefits.

New Design France Bergeaud Cone Liner Manganese

9 小时之 After-sales Service: Available Warranty: 12 Months Certification: ISO 9001:2000, ISO 9001:2008 Standard: GB, ASTM Surface Treatment: Polishing Manufacturing Process: Casting