Slag Grinding Mill With High Fineness

Slag grinding with the Polysius Roller Mill in China

2007年2月1日 The slag grinding plant in Nanchang is in operation since November 2005. The roller mill is a type RMS-51/26 with an SEPOL RMS-435 separator. For a feed

CementBlast Furnace Slag Loesche

2023年3月3日 Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind

Water Slag HC Super Large Grinding Mill

The fineness can achieve 0.18mm(80 mesh) to 0.038mm(400 mesh), and maximum capacity reach 40t/h. The powder processed by Water Slag Grinding Mill can be used as

News Technology of Steel Slag Grinding Mill For Steel

Compared with the ordinary vertical roller mill, our grinding fineness is finer, the particle size can be controlled to more than 700 meters, and the power consumption of the main

Slag grinding by roller press—major issues ScienceDirect

1998年2月1日 Process. 53 (1998) 87-97 Inl~HTIOHi JOURflAL OF alBERto. IJRO [ENNIU6 Slag grinding by roller press major issues S.M. Mehra The Tata Iron and Steel

What is a suggested slag grinding mill? gkmill

2021年1月20日 Finally the finished products with uniform fineness are got and the pass-through screening rate is high. When slag vertical grinding mill works, the process

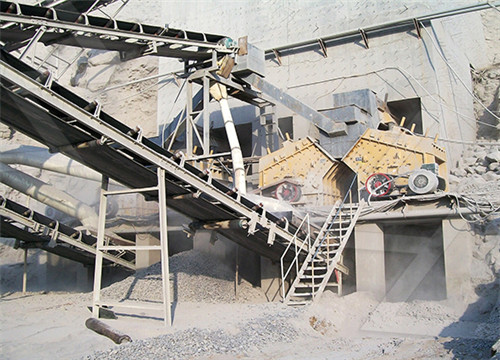

Slag Grinding Plant Slag Mill, Slag Grinding Mill AGICO

2023年2月1日 Slag grinding plant equipment. The complete set of equipment is mainly composed of jaw crusher, bucket elevator, cement silo, vibrating feeder, slag mill, fan,

Vertical grinding mill to make ground,

While grinding the slag, the fineness will be as per Blaine>4,200 cm 2 /gram. The initial moisture of 15% in the slag will be reduced to 0.5% in the process. Advantages of vertical roller mill 20-50% less energy needed

How Much Is the Vertical Slag Grinding Mill linkedin

2020年4月3日 Hcmilling (Guilin Hongcheng) New Environmentally Friendly Mill-HC Vertical Grinding Mill. Max feeding size: ≤30mm. Capacity: 6-25t/h. Fineness: 0.18-0.038mm

VRM THE LATEST TECHNOLOGY Bashundhara Cement

Suitable grinding bed is easily obtained in vertical roller mill with high efficiency separator which ensures high fineness of product. Superiority. A. The grinding process of Ball mill

Study on the Properties of High-Performance Ground Iron

2020年11月16日 The influence of the fineness and content of steel slag powder on the fluidity and strength of the powder mortar was studied, the regression equations of fluidity and compression strength of different ages are derived, and the contour map is drawn. 495, 559, and 592 m 2 /kg were prepared by grinding with φ = 500 × 500 mm ball mill.

Effects of carbonation degree on the hydration reactivity

Granular steel slag was provided by a steel plant in Jiangsu, China. Steel slag powders with particle size smaller than 80 μm and Blaine's fineness of 337 m 2 /kg was obtained after 30 min grinding with a small ball mill. P.I 52.5 Portland cement was provided by Hubei Jinglan Cement Group Co. ltd, Hubei, China.

GGBS Production Line Slag Mill for Slag Powder Grinding

Making full use of the high-efficiency grinding mechanism of the roller press, these systems have high grinding efficiency, and their energy consumptions are lower than that of the ball mill grinding systems. The unit power consumption of this process is about 50~60kWh/t per grinding slag with a specific surface area of 450m 2 /kg. However, the

Improved Processing of Blended Slag Cement Through

2004年1月5日 EAFS were identified with respect to its fineness as slag ground (SG), slag-fine (SF) 100% passing 75 μm sieve, and slag-super-fine (SSF) 100% passing 45 μm sieve. Compressive strength was

mill Slag industry news from Global Slag

2018年12月20日 Pfeiffer for its Nardana plant in Rajasthan. The order includes a MVR 6000 C-6 mill for grinding slag cement and a MPS 3070 BK mill for grinding fuel. Delivery is scheduled for early 2019 and mid-2019 respectively. The MVR mill will feature a total drive power of 5820kW. Mixed cements will be be ground to a fineness of up to 5% R 45µm.

Review of 12th Global Slag Conference 2017

2017年5月19日 The mill can produce up to 450t/h of 34% slag cement at 4420 Blaine. The mill has the possibility of operating with fewer than six rollers, and with fewer than six drives. while at the same time providing high grinding fineness. Stefan suggests that roller presses use around 3-5kWh/t less compared to a VRM to grind slag to the same fineness

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers .

Water Slag HC Super Large Grinding Mill

The fineness can achieve 0.18mm(80 mesh) to 0.038mm(400 mesh), and maximum capacity reach 40t/h. The powder processed by Water Slag Grinding Mill can be used as high-quality cement raw materials, but also can be made into slag Portland cement, gypsum, slag cement, lime, slag cement, slag brick and slag concrete.

Options for Grinding Slag and Pozzolan for Use as

2022年12月13日 8. High Pressure Grinding Rolls. High pressure grinding rolls (HPGR) technology was first utilized in the grinding of clinker and raw material in the mid-1980s and has quickly proved be an economical choice in comminution process. 3 It utilizes the same compression method as the VRM to break the particles to the desired fineness. The

China 0-5 Mm Output Sand Making Equipment Energy

2023年3月9日 China 0-5 Mm Output Sand Making Equipment Energy Saving Rod Mill and slag rod mill for, Find details about China Ore Grinding Mill from 0-5 Mm Output Sand Making Equipment Energy Saving Rod Mill and slag rod mill for Luoyang Zhongtai Industrial Co., Ltd..

GLOBAL CEMENT: SLAG GRINDING KHD Humboldt

2021年12月21日 mills for slag grinding F or many decades granulated blast furnace slag than the VRM to grind the slag to a fineness of 4000 4200 cm²/g. These data were collected during a very wear-resistant grinding tools and high pressure to comminute effi ciently but not at the expense of excessive wear. Both advantages can be combined

Effects of carbonation degree on the hydration reactivity

Granular steel slag was provided by a steel plant in Jiangsu, China. Steel slag powders with particle size smaller than 80 μm and Blaine's fineness of 337 m 2 /kg was obtained after 30 min grinding with a small ball mill. P.I 52.5 Portland cement was provided by Hubei Jinglan Cement Group Co. ltd, Hubei, China.

Effect of wet-grinding steel slag on the properties of

2021年6月7日 Although wet-grinding steel slag improved pore distribution at age of 3 d and 28 d, the compressive strength of 3 μm-40% specimen was lower than that of plain cement (Fig. 10 and Fig. 11); It might be attributed to the poor cementitious capability of steel slag at early and middle age . Download : Download high-res image (571KB)

GGBS Production Line Slag Mill for Slag Powder Grinding

Making full use of the high-efficiency grinding mechanism of the roller press, these systems have high grinding efficiency, and their energy consumptions are lower than that of the ball mill grinding systems. The unit power consumption of this process is about 50~60kWh/t per grinding slag with a specific surface area of 450m 2 /kg. However, the

Improved Processing of Blended Slag Cement Through

2004年1月5日 EAFS were identified with respect to its fineness as slag ground (SG), slag-fine (SF) 100% passing 75 μm sieve, and slag-super-fine (SSF) 100% passing 45 μm sieve. Compressive strength was

Slag HLM Vertical Roller Mill hcmilling

HCMilling(Guilin Hongcheng) provides exclusive Slag Vertical Roller Mill equipment with customers for grinding Slag powder. It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying. Its fineness can achieve 200-325 mesh (75-44μm). The production capacity is 5-200T/H. It is applied as a good

Slag Grinding Mill,Slag Grinding Plant Clirik

2021年8月20日 To make slag into powder, to processing slag ,we have slag grinding mill which can also be called slag grinding machine, slag grinding plant, slag grinding equipment, slag pulverizer, slag micronizer.

Silica Sand Slag Rod Ball Grinding Mill Cement Clinker

Quality Silica Sand Slag Rod Ball Grinding Mill Cement Clinker Grinding Ball Mill Production Line find quality Ore Beneficiation Machine, Mine MillOre Beneficiation Machine from Zhengzhou VANGUARD Machinery Technology Co., Ltd. of China Suppliers .

What is a suggested slag grinding mill? gkmill

2021年1月20日 Finally the finished products with uniform fineness are got and the pass-through screening rate is high. When slag vertical grinding mill works, the process includes feeding, grinding, drying, collection and slag discharging. The process is reasonable and the system is compact. Moreover, the roller grinds materials directly on the grinding disc

China 0-5 Mm Output Sand Making Equipment Energy

2023年3月9日 China 0-5 Mm Output Sand Making Equipment Energy Saving Rod Mill and slag rod mill for, Find details about China Ore Grinding Mill from 0-5 Mm Output Sand Making Equipment Energy Saving Rod Mill and slag rod mill for Luoyang Zhongtai Industrial Co., Ltd..