Horizontal Stirred Mill Specification

Performance Comparison of the Vertical and Horizontal

2023年1月31日 The Tower Mills can cope with 6 mm top size; hence, it should utilize coarser balls inside the chamber. Therefore, the comparisons of the two mills may not be

-Horizontal stirred mill specifications Download Table

Download Table -Horizontal stirred mill specifications from publication: Energy and cost comparisons of hpgr-based circuits | ResearchGate, the professional network for

Utilization of grinding aids in dry horizontal stirred milling

2015年12月1日 Pilot scale dry horizontal stirred mill was developed for this purpose with the partnership of Netzsch-Feinmahltechnik GmbH. The mill was tested in cement

Vertimill® Metso Outotec

Metso Outotec Vertimill® Energy efficient gravity induced mill. Vertimill® is a unique product offered exclusively by Metso Outotec. Grinding efficiency, reduced media

HIGmill high intensity grinding mill Metso

High intensity grinding mill. The Metso Outotec HIGmill™ is an advanced, energy-efficient fine and ultra-fine grinding solution that utilizes proven technology. With the tall, narrow, vertical body arrangement, grinding

Regrinding and fine grinding technology the facts and

2016年6月3日 ISAMILL® is in fact a large version of the Netszch horizontal stirred mill which was being used To make this horizontal mill suitable for use in the mining

Attritor Ball Mill WetDry Grinding Stirred Ball Mill

Capacity: 15-1000 L. Motor Power: 3-55KW. Material: coal, clay, various ores, cement, fireproof materials, metallurgical materials, etc. SEND INQUIRY. GET QUOTATION. The

(PDF) Industrial Vertical Stirred Mills Screw Liner Wear

2021年4月10日 Data from a vertical stirred mill screw liner wear measurement obtained in a full-scale mill ar e used to correlate with simulation results. The results indicate a

Horizontal Stirred Mill Specification centrumvalve.pl

2021年2月28日 Horizontal Stirred Mill Specification Home Horizontal Stirred Mill Specification. Our Offered Machines to you. Who are in extremely love with eco friendly

ISAMILL FINE GRINDING TECHNOLOGY AND ITS

2023年2月4日 The IsaMill is a horizontal high speed stirred mill that operates with very high power intensities (up to 350 kW/m3). In comparison, the power intensity of a ball mill is about 20 kW/m3. The high power intensity enables the IsaMill to process fine particles at a high throughput that is essential for the economics of the minerals industry.

VXPmill for fineultra fine grinding

There is a large gap between the tip speed and power intensity of the low-speed vertical mills and the high-speed horizontal mills. The VXP mill bridges the gap between high-speed and low-speed mills. The VXPmills

-Horizontal stirred mill specifications Download Table

Download Table -Horizontal stirred mill specifications from publication: Energy and cost comparisons of hpgr-based circuits | ResearchGate, the professional network for scientists.

The Influence of Stirred Mill Orientation on Calcite Grinding

2021年4月21日 Therefore, comparisons of grinding performance were also carried out considering stirred mill orientation (vertical/horizontal) using the stress energy model. The stress intensity SI GM was altered by changing the stirrer tip speed v tip (between 1 m/s and 10 m/s) and the grinding media size d GM (between 3 and 4 mm).

*C. Wang,S. Nadolski,O. Mejia,J. Drozdiak,B. Klein

2018年2月20日 Horizontal stirred mill A Netzsch M20 horizontal stirred mill (configured with discs to IsaMill TM specifications) was used to conduct the signature plot testing for the purpose of scale -up. Signature plot tests are an industry accepted method for sizing IsaMills TM based on laboratory scale test results; a scale -up ratio of 1:1 is

Grinding Mills Mineral Processing Equipment

2022年3月18日 To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW. Our large-size grinding mills hold a market share of 85% in

Grinding and Dispersing with Stirred Media Mills

2018年5月7日 The knowledge of the physical phenomena inside the mill and the industrial applications have increased significantly in the last 15 years. The course gives an overview about today‘s mill designs available on the market and about the physical phenomena of grinding and dispersing in stirred media mills.

Vertimill VS Ball Mill GrindingClassification Circuits

2023年3月2日 If we instead focus on wet grinding, we should differentiate between stirred media grinding, which can be both vertical and horizontal, and tumbling mills with manufactured grinding bodies. A continuous grate-discharge tumbling mill with grinding balls does seldom have ball size below 20 mm since you then will have unacceptable media

Supplier of Horizontal Laboratory Bead Mill in

Horizontal Bead Mill Supplier in India. Horizontal Lab Bead Mills are used for development of products. Use of small grinding media of 0.6mm for grinding down to nano-meter range. Minimal loss of product and result in a short

Horizontal Stirred Mill Specification centrumvalve.pl

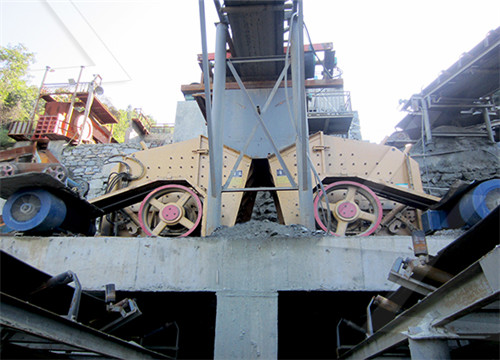

2021年2月28日 Horizontal Stirred Mill Specification Home Horizontal Stirred Mill Specification. Our Offered Machines to you. Who are in extremely love with eco friendly system.. HGT Hydraulic Gyratory Crusher. HGT Gyratory Crusher is a new-type intelligent coarse crusher with big capacity and high efficiency. It integrates mechanical, hydraulic,

IsaMill™ Glencore

IsaMill™ uses horizontal milling to secure better energy efficiency, product size and availability The IsaMill™ has real-world success in 133 metalliferous installations across 21 countries. It’s the world’s only horizontal fine-grinding mill, so it avoids short-circuits, is highly efficient and gives the highest availability.

Structural Improvement on Cylinder of Horizontal Ultrafine

2023年1月1日 [7] Beinert S, Fragniere G, Schilde C and Kwade A 2015 Analysis and modelling of bead contacts in wet-operating stirred media and planetary ball mills with CFD-DEM simulations Chemical Engineering Science 134 648-62. Google Scholar [8] Blecher L, Kwade A and Schwedes J 1996 Motion and stress intensity of grinding beads in a stirred

ISAMILL FINE GRINDING TECHNOLOGY AND ITS

2023年2月4日 The IsaMill is a horizontal high speed stirred mill that operates with very high power intensities (up to 350 kW/m3). In comparison, the power intensity of a ball mill is about 20 kW/m3. The high power intensity enables the IsaMill to process fine particles at a high throughput that is essential for the economics of the minerals industry.

Stirred Milling Technology A New Concept in Fine

2019年5月8日 Fig. 3 Vertical stirred media mill flow sheet (Outotec, 2012) 194 Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 17 July 2013, Perth WA High power intensity and energy efficiency In stirred media grinding, the energy intensity (kW/m³) is very high versus tumbling mills. In the

Metso Vertimills® Metso Corporation PDF Catalogs

Metso Vertimills® Unlocking energy efficiency in fine wet grinding VERTIMILL® is Metso’s gravity-induced, vertical stirred mill. Its vertical configuration allows for large throughputs while maintaining a small footprint in your circuit. availability and longevity Spare and wear parts Crafted to the same strict specifications and

CFD MODELLING OF A STIRRED BEAD MILL FOR FINE

1999年11月11日 Netzsch horizontal bead mill. This mill was chosen because it follows a commonly-used design, and in addition some experimental data has been obtained for this mill which may be used for comparison with CFD predictions. BACKGROUND Stirred bead mills consist basically of an enclosed water-jacketed cylindrical vessel fitted with an

(PDF) Optimization of some parameters of

Optimization of some parameters of stirred mill for ultra-fine grinding of refractory Au/Ag ores . × As horizontal ball mills show decreasing efficiency as grinding sizes are finer than 50 m, this work shows

Evolution of grinding energy and particle size during dry

2023年2月28日 Chen et al. [8] showed for an oscillatory ball mill that the median particle diameter d 50 (and also other percentiles such as d10 and d90) were well fitted by Rittinger’s model for the grinding of D-Lactose from 450 to 150µm. For experiments on spruce saw dust on the same type of mill, Karinkanta et al. [9] showed, however, that d 50

Bead-Mills Vollrath GmbH

The mill-base is pumped through the grinding chamber and the disc rotation move the beads and mill-base mixture at high speed. The product is separated from the grinding beads at the outlet by a slotted screen. VOLLRATH supplies vertical bead mills respectively agitator ball mills with a vertically arranged grinding chamber.

Horizontal Stirred Mill Specification centrumvalve.pl

2021年2月28日 Horizontal Stirred Mill Specification Home Horizontal Stirred Mill Specification. Our Offered Machines to you. Who are in extremely love with eco friendly system.. HGT Hydraulic Gyratory Crusher. HGT Gyratory Crusher is a new-type intelligent coarse crusher with big capacity and high efficiency. It integrates mechanical, hydraulic,