Water Spray In A Crusher Unit 1

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER SPRAY, AWR / MPI / DISTRICT 4/9/96 METHODOLOGY (1 0.5) Eh = Uh x EF x Ci x (1 0.5) (Ducted

C21 FINES CRUSHING, FINES MATERIAL, DRY, WATER

- The PM10 factor is based upon the uncontrolled PM10 fines crushing value in Section 11.19.2, Table 11.19.2-2 of AP-42 (1/95) and the District AWR MPI agreement dated

11.19.1 Sand And Gravel Processing US EPA

water spray Rodmilling (3-05-025-22) Scalping Screening (3-05-025-11) Raw Material Transport (3-05-025-04) Raw Material Storage (3-05-025-07) Mining Product Storage

Texas Commission on Environmental Quality

Washed Sand/gravel with water spray 50-85 0.5-0.15 Partial Enclosure* Full enclosure* Enclosed by building* *If an enclosure is claimed, the applicant must provide a

water sprays to suppress crusher dust reflexovermere

Water Spray In A Crusher Unit. Effective Affordable Water Spray Systems for Dust Control Effective Affordable Water Spray Systems for Dust Control NESCO Dr Dust

Mesda Crusher Water Spray System to control the dust

49 views, 1 likes, 0 loves, 0 comments, 0 shares, Facebook Watch Videos from Mesda Crusher: Water Spray System to control the dust at the mobile crusher job site.

Wet Dust Collector Airex Industries

Spray-Wash System In environments where the filter can clog (e.g. in stone or textile industries), the addition of a spray nozzle system will reduce the need for filter cleaning if

Spray Bars Conveyor Cleaning System DYNA Engineering

A spray bar is a pipe arrangement with several spray nozzles fittings used to disperse a liquid, usually water, in a desired pattern to assist with cleaning the conveyor belt or

Dust Suppression Systems Cannons, Nozzles, and

Available with in-built generator and large water bowser for a truly turn key solution. View Range Rotary Atomisers Using water and a powerful fan, RA’s spray a fine fog 15-20m+

FactSheet Occupational Safety and Health Administration

airborne dust when using crushing machines as listed in Table 1 of the Respirable Crystalline Silica Standard for Construction 29 CFR 1926.1153. Engineering Control Method: Wet Methods AND Operator Isolation The use of water sprays or mists for dust suppression at the points where dust is generated (e.g., hoppers, conveyers, sieves/

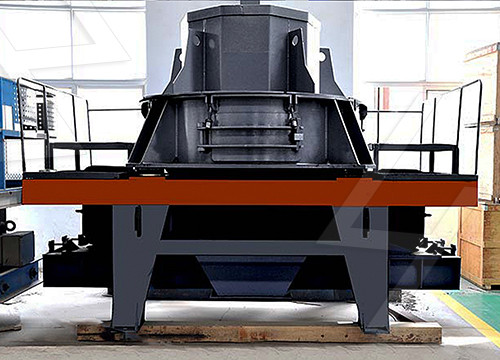

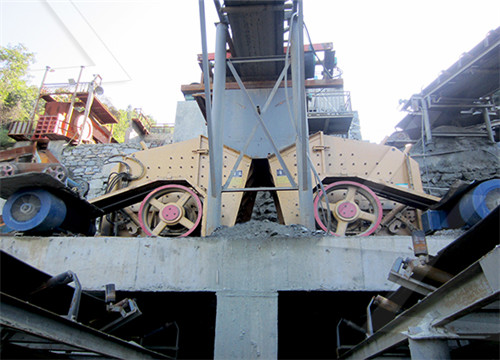

CNU Water spray system of double-geared roller crusher

The utility model relates to a water spray system of a double-geared roller crusher. The water spray system comprises a crusher body; the crusher body is internally provided with two crushing rollers which are arranged in parallel; water spraying valve blocks are arranged on two side walls of the crusher body and are communicated with a water tank; nozzles

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER SPRAY, AWR / MPI / DISTRICT 4/9/96 METHODOLOGY (1 0.5) Eh = Uh x EF x Ci x (1 0.5) (Ducted Releases) Ea = 0 Eh = 0 NOTES: The AWR / MPI / District Crushing Operation Emission Factors for this material are 0.00070 lbs PM10 and 0.00148 lbs TSP per t on of material

Reduction of Respirable Silica Following the Introduction of

water-spray equipment to improve dust control in their operations. As word of the study spread throughout the cluster with the help of the local crusher owners’ asso-ciation, over 40 mill owners agreed to install water spray systems from an Indian supplier. This pilot study inves-tigated the efficacy of the water spray system to reduce

Reduction of Respirable Silica Following the Introduction of Water

DOI: 10.1179/oeh.2008.14.2.94 Corpus ID: ; Reduction of Respirable Silica Following the Introduction of Water Spray Applications in Indian Stone Crusher Mills @article{Gottesfeld2008ReductionOR, title={Reduction of Respirable Silica Following the Introduction of Water Spray Applications in Indian Stone Crusher Mills}, author={Perry

MR 130i EVO2 Mobile impact crusher Wirtgen Group

The mobile impact crusher MOBIREX MR 130i EVO2 can be deployed universally as an all-rounder and produces first-class final grain quality. With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plants. This is made possible by outstanding cost effectiveness and

Repairing/ Replacement of water spray system at different coal

2023年3月2日Find latest tenders for Repairing/ Replacement Of Water Spray System At Different Coal Transfer Units Under Secondary Crusher House And Input And Output Units Of Ns- 1 And Ns- 2 Junction House At Moonidih Coal Washery. at Primetenders,Tenders available in Jharkhand. Primetenders provides active Repairing/ Replacement Of Water

water spray in a crusher unit jakkalsvallei.co.za

Rubble Master 100 GO! Crusher On-Site Recycling. Dust suppression using water spray inside crusher and at outlet and belts Diesel filling pump Crusher hammer changing system Cable remote control Central lubrication system Subfloor: Add-on equipment: RM MS100GO! mobile single-deck screen box for RM 100GO!, screen area 2.8 x 1.3 m with

water spray in a crusher unit

Water Spray In A Crusher Unit-Crusher. Equipment Aggrebind. Crush the road with the meri crusher or similar equipment to a depth of 25mm add 25 of 200 sieve fines to the crushed asphalt if necessary spray this with a mixture of 1 part aggrebind mixed with 2 parts water at a rate of . get price

water spray in a crusher unit karmeniskola

Aggregates Industry uses Diesel Generators. It is not uncommon for rock crushers to contain a water system with nozzles to lightly spray the rocks prior to crushing However this does not completely reduce production of dust Movement from a crusher with a larger rock classification to a crusher with a smaller classification then to the finish pile always

using of spray water to control dust in crusher github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Lokotrack® LT200HP™ mobile cone crusher Metso Outotec

Lokotrack LT200HP™ mobile crusher is available with an extended main conveyor to allow more feeding height for downstream crushing and screening processes. It can also be delivered with dust encapsulation, a discharge hood, a high-pressure water spray system, or a special scraper to clean the conveyor belt.

FAQ: Tips and Techniques for using Crusher fines surfacing for trails

Best Practices: For use in trail surfacing, the material should be composed of irregular angular particles that interlock and bind into a firm matrix. The rock particles should range in size from dust to 3/8 inch. Gravel and crusher fines differ from one another in that gravel is screened to remove the fines which contain the natural binders

Puzzi 10/1 Kärcher kaercher

Hotline: 1-300-22-3188. Puzzi 10/1 with upholstery nozzle and floor nozzle is particularly suited to hygienic and effective cleaning of small to medium surfaces. With 1 bar spray pressure, the spray extraction machine ensures gentle, deep cleaning of textiled surfaces and delivers impressive results, especially when cleaning car and upholstery.

FactSheet Occupational Safety and Health Administration

airborne dust when using crushing machines as listed in Table 1 of the Respirable Crystalline Silica Standard for Construction 29 CFR 1926.1153. Engineering Control Method: Wet Methods AND Operator Isolation The use of water sprays or mists for dust suppression at the points where dust is generated (e.g., hoppers, conveyers, sieves/

C21 FINES CRUSHING, FINES MATERIAL, DRY, WATER

- The PM10 factor is based upon the uncontrolled PM10 fines crushing value in Section 11.19.2, Table 11.19.2-2 of AP-42 (1/95) and the District AWR MPI agreement dated 4/9/96. The TSP factor is calculated using a (0.74/0.35) ratio of particle size multipliers from Section 13.2.4 of AP-42 and the abov e PM10 value.

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER

C02 PRIMARY CRUSHING, PRIMARY MATERIAL, WATER SPRAY, AWR / MPI / DISTRICT 4/9/96 METHODOLOGY (1 0.5) Eh = Uh x EF x Ci x (1 0.5) (Ducted Releases) Ea = 0 Eh = 0 NOTES: The AWR / MPI / District Crushing Operation Emission Factors for this material are 0.00070 lbs PM10 and 0.00148 lbs TSP per t on of material

Reduction of Respirable Silica Following the Introduction of

water-spray equipment to improve dust control in their operations. As word of the study spread throughout the cluster with the help of the local crusher owners’ asso-ciation, over 40 mill owners agreed to install water spray systems from an Indian supplier. This pilot study inves-tigated the efficacy of the water spray system to reduce

Reduction of Respirable Silica Following the Introduction of Water

DOI: 10.1179/oeh.2008.14.2.94 Corpus ID: ; Reduction of Respirable Silica Following the Introduction of Water Spray Applications in Indian Stone Crusher Mills @article{Gottesfeld2008ReductionOR, title={Reduction of Respirable Silica Following the Introduction of Water Spray Applications in Indian Stone Crusher Mills}, author={Perry

MR 130i EVO2 Mobile impact crusher Wirtgen Group

The mobile impact crusher MOBIREX MR 130i EVO2 can be deployed universally as an all-rounder and produces first-class final grain quality. With a crusher inlet width of 1300 mm, it achieves a production rate that until now was only associated with considerably larger crushing plants.

Mesda Crusher Water Spray System to control the dust at...

49 views, 1 likes, 0 loves, 0 comments, 0 shares, Facebook Watch Videos from Mesda Crusher: Water Spray System to control the dust at the mobile crusher job site. mesda-crusher Mail:...

water spray in a crusher unit jakkalsvallei.co.za

Rubble Master 100 GO! Crusher On-Site Recycling. Dust suppression using water spray inside crusher and at outlet and belts Diesel filling pump Crusher hammer changing system Cable remote control Central lubrication system Subfloor: Add-on equipment: RM MS100GO! mobile single-deck screen box for RM 100GO!, screen area 2.8 x 1.3 m with

Repairing/ Replacement of water spray system at different coal

2023年3月2日Find latest tenders for Repairing/ Replacement Of Water Spray System At Different Coal Transfer Units Under Secondary Crusher House And Input And Output Units Of Ns- 1 And Ns- 2 Junction House At Moonidih Coal Washery. at Primetenders,Tenders available in Jharkhand. Primetenders provides active Repairing/ Replacement Of Water

water spray in a crusher unit karmeniskola

Aggregates Industry uses Diesel Generators. It is not uncommon for rock crushers to contain a water system with nozzles to lightly spray the rocks prior to crushing However this does not completely reduce production of dust Movement from a crusher with a larger rock classification to a crusher with a smaller classification then to the finish pile always

using of spray water to control dust in crusher github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Vertical Roller Mills And Water Spray Crusher Mills, Cone Crusher

Spray nozzle Patent #: Issued on: 06/27/1978 of the coarse powder to be returned to the vertical roller mill is be ground such as water alone or a mixture of water vertical roller mill

FAQ: Tips and Techniques for using Crusher fines surfacing for trails

Water running down the slope gathers on the crusher fines trail because of insufficient cross slope of the trail. A better crusher fines trail in the same Bluff Lake Nature Area, Denver Here the edging keeps water from draining so obstacles in the form of drainage bars were placed to try to keep the crushed rock from eroding.

Puzzi 10/1 Kärcher kaercher

Hotline: 1-300-22-3188. Puzzi 10/1 with upholstery nozzle and floor nozzle is particularly suited to hygienic and effective cleaning of small to medium surfaces. With 1 bar spray pressure, the spray extraction machine ensures gentle, deep cleaning of textiled surfaces and delivers impressive results, especially when cleaning car and upholstery.

- 深圳慧康特点

- 石灰岩粉碎机

- 分各轮给料机河南万泰机械有限公司

- Small Capacity Cone Crusher

- 石英石砂石料生产线

- Dolomite Crusher India

- 超细粉球磨机钢渣球磨机

- 海南五指山矿石

- Durable In Use Ep Conveying Belt

- Literature Review For Crusher Dust Foundry Sand Facts For Civil Engineer

- 粉煤灰的工艺流程

- Mobile Crusher Mining Equipments

- 什么样的石膏粉做出来的像硬度像陶瓷

- 除磨机

- Sand Suppliers In Bloemfontein