Screw Conveyor Conveyor Belt Conveyor System

All About Screw Conveyors Types, Design, and Uses Thomasnet

What Are Screw Conveyors?Types of Screw ConveyorsSpecifications and Selection CriteriaSummaryOther Conveyors Articles

The screw conveyor is one of the most popular choices for processing and manufacturing, meaning there are many, many iterations of this design. This section will go through a general classification of screw conveyors available and what sets them apart from other unique designs. Note that, because they are so widely used, screw conveyors can either

Types of Screw Conveyors Engineering Guide

根据热度为您推荐•反馈

Screw conveyor for inhomogeneous bulk materials BEUMER Group

Designed as a panned auger conveyor or tubular screw conveyor, the auger continuously conveys flow of the material simultaneously dispensing the correct dosage. The screw

When to Choose a Belt Conveyor Over a Screw Conveyor

Belt conveyors are available up to 72” wide and can operate at speeds up to 600 feet per minute (FPM), making them the preferred choice for any type of high-capacity setting. When Handling Stringy Materials Both belt

Helix® Flexible Screw Conveyor Hapman

Portable Helix ® Flexible Screw Conveyor. Up to 8″ diameter. Exclusive T-handle couplings allow the conveyor to be disassembled in minutes for cleaning and maintenance. The largest selection of flexible auger styles

Belt Conveyors: Components, Types, Design, and Applications

A belt conveyor is a system designed to transport or move physical items like materials, goods, even people from one point to another. Unlike other conveying means that

Screw Conveyors 5 Mistakes to Avoid ISC

A properly sized screw conveyor will operate between 30 and 120 RPMs. Often, we operate screw feeders at less than 30 RPMs based on the volume of material needed to

SCREW CONVEYOR pneuCONVEYOR systems

2023年3月7日Screw conveyors can be designed without a center pipe. This type of conveyor is called a shaft less screw conveyor and is designed for conveying wet, sticky, sluggish products such as industrial

ThomasMuller Systems Ltd. Screw Conveyors

Screw conveyors, or auger conveyors, are industrial equipment used in transporting bulk quantities of granular solids (e.g., powder, grains, granules), semi-solids, liquids, and even non-flowing materials from one

All About Screw Conveyors Types, Design, and

2 之The horizontal screw conveyor is the most distributed version of the screw conveyor, thanks to its simple and easy to use design. They can convey materials at 15-45% trough loading, defined as the maximum

Screw conveyor Wikipedia

Screw conveyors can be operated with the flow of material inclined upward. When space allows, this is a very economical method of elevating and conveying. As the angle of inclination increases, the capacity of a

Conveyors Hapman

Hapman conveyors offer the simplest, easiest operation and maintenance on the market. Flexible screw, vacuum, and tubular drag designs give you the ultimate in versatility to move almost any bulk material. They’re designed and built to provide a long service life in your operations. Helix ® Flexible Screw Conveyor. Vacuum Conveyors.

Bulk Material Handling Hapman

4. Helix ® Flexible Screw Conveyor . Hapman Helix® Flexible Screw Conveyors are the most efficient, flexible and easy to operate and maintain conveyors on the market. Our multiple design options let you tailor a Helix ® flexible screw conveyor to the flow rate, capacity, sanitation, and durability specifications you need to operate your

Screw Conveyors 5 Mistakes to Avoid ISC

A properly sized screw conveyor will operate between 30 and 120 RPMs. Often, we operate screw feeders at less than 30 RPMs based on the volume of material needed to feed into a subsequent process. Factors such as the size of the conveyor, the type of material being transported, and the desired throughput rate affect the RPM selection.

What is a screw conveyor used for? linkedin

2023年3月9日Screw Conveyor is used to transport powdery, granular and small block materials. Since the use environment of Screw Conveyor is generally dusty, the wear of the conveyor's bearings will be

Maine Conveyor, Inc. Screw Conveyors

A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller. The construction of individual systems depends on the materials...

Inclined Screw Conveyor Horizontal screw conveyor Used

For sale: Inclined Screw Conveyor Horizontal screw conveyor and many other used Industrial Horizontal screw conveyors. Worldwide shippingtested quality! Just give us a call! +31 (0)342 415 551 Conveying systems chevron_right. Horizontal screw conveyors chevron_right. Inclined Screw Conveyor Horizontal screw conveyor. Inclined Screw

Belt Conveyor system for educational purposes only YouTube

#belt#beltconveyor#conveyor#beltconveyorsystem

P-Tech Sales And Services Manufacturer of Screw Conveyor

Screw Conveyor, Filtration SystemMagnetic Separator Manufacturer offered by P-Tech Sales And Services from Hubli, Karnataka, India

When to Choose a Belt Conveyor Over a Screw

When Handling High Throughput. Capable of handling material at up to 8,000 TPH, belt conveyors can handle much higher capacities than screw conveyors. Belt conveyors are available up to 72” wide and can

Design and fabrication of a screw conveyor ResearchGate

2017年10月1日The conveyor is powered by an electric motor through a V belt connection. Tests were run on the conveyor using common granular materials like maize, sorghum and gari at 13% moisture content. The

Conveyor Systems • Con Belt

2021年7月27日A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller. The construction of individual systems depends on the materials to be moved, which includes their weight, dimensions, and

ThomasMuller Systems Ltd. Screw Conveyors

A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller.

All About Screw Conveyors Types, Design, and

2 之The horizontal screw conveyor is the most distributed version of the screw conveyor, thanks to its simple and easy to use design. They can convey materials at 15-45% trough loading, defined as the maximum

Screw Conveyor SystemsParts Screw Conveyor

Screw conveyors are also more economical alternatives to a belt, pneumatic, or aeromechanical conveying device. Using multiple inlets and discharge points, screw conveyors efficiently distribute bulk materials to

Conveyors Hapman

Hapman conveyors offer the simplest, easiest operation and maintenance on the market. Flexible screw, vacuum, and tubular drag designs give you the ultimate in versatility to move almost any bulk material. They’re designed and built to provide a long service life in your operations. Helix ® Flexible Screw Conveyor. Vacuum Conveyors.

Bulk Material Handling Hapman

4. Helix ® Flexible Screw Conveyor . Hapman Helix® Flexible Screw Conveyors are the most efficient, flexible and easy to operate and maintain conveyors on the market. Our multiple design options let you tailor a Helix ® flexible screw conveyor to the flow rate, capacity, sanitation, and durability specifications you need to operate your

Screw Conveyors 5 Mistakes to Avoid ISC

A properly sized screw conveyor will operate between 30 and 120 RPMs. Often, we operate screw feeders at less than 30 RPMs based on the volume of material needed to feed into a subsequent process. Factors such as the size of the conveyor, the type of material being transported, and the desired throughput rate affect the RPM selection.

What is a screw conveyor used for? linkedin

2023年3月9日Screw Conveyor is used to transport powdery, granular and small block materials. Since the use environment of Screw Conveyor is generally dusty, the wear of the conveyor's bearings will be

Maine Conveyor, Inc. Screw Conveyors

A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller. The construction of individual systems depends on the materials...

Inclined Screw Conveyor Horizontal screw conveyor Used

For sale: Inclined Screw Conveyor Horizontal screw conveyor and many other used Industrial Horizontal screw conveyors. Worldwide shippingtested quality! Just give us a call! +31 (0)342 415 551 Conveying systems chevron_right. Horizontal screw conveyors chevron_right. Inclined Screw Conveyor Horizontal screw conveyor. Inclined Screw

Belt Conveyor system for educational purposes only YouTube

#belt#beltconveyor#conveyor#beltconveyorsystem

P-Tech Sales And Services Manufacturer of Screw Conveyor

Screw Conveyor, Filtration SystemMagnetic Separator Manufacturer offered by P-Tech Sales And Services from Hubli, Karnataka, India

Design and fabrication of a screw conveyor

2017年10月1日The conveyor is powered by an electric motor through a V belt connection. Tests were run on the conveyor using common granular materials like maize, sorghum and gari at 13% moisture content. The

Conveyor Systems • Con Belt

2021年7月27日Screw conveyors are known as auger, helix, and spiral conveyors. The blades of the screw flights are designed to carry the material upwards. Screw Conveyor Pneumatic Conveyors– Pneumatic conveyors transport bulk materials using a pressurized gas that pushes the material through a sealed pipeline.

ThomasMuller Systems Ltd. Screw Conveyors

A conveyor system is a method for moving packages, products, supplies, parts, and equipment for production, shipping, or relocation. The different types of conveying systems include pneumatic, screw, belt, and roller.

Sortation Innovation: A Simple Intro To Sortation Conveyors

2 Sortation conveyors rely on the help of equipment and techniques such as diverters, gates, pushers, and lane guiding to help move product where it needs to go [1]. These helpers are driven by smaller pieces of equipment like photo eyes, counters, and proximity switches to determine which types of material need to go in which direction,

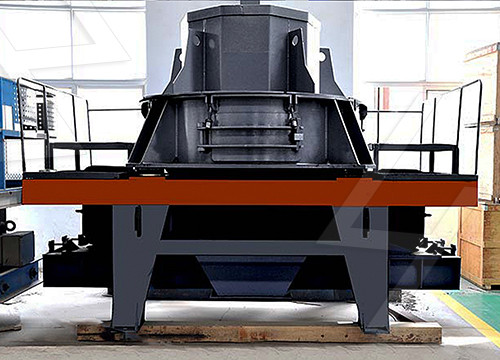

- 碎石粉

- Gold Mining Machinery Ceramic Slurry Ball Mill For Sale

- 1315重型反击破与一般反击破区别

- Filling Grinding Tools

- 破碎机破碎挖石方套用什么公路定额

- Used Stone Stationery Crushers Horiontal Shaft Impact Tph U

- 钢渣旋风破碎机

- 重庆煤灰空心砖

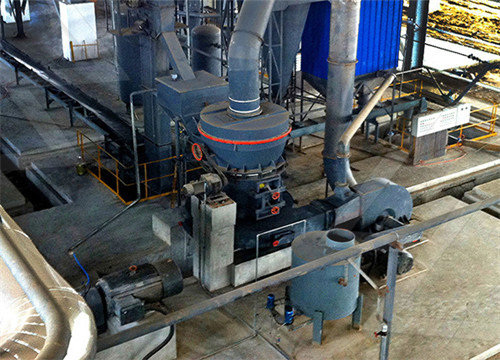

- 磨陶瓷设备

- 粉磨站烘干机巡检点位

- 全自动陶瓷生产设备

- 河南和谐机机械厂

- Mills Crystals Tunisia

- Barrel Washer Using Coal Slurry As Media Crusher For Sale

- 矿山机械设备企业排名