Drum Autogenous Mills Offers

(PDF) Design of a typical Autogenous Mill: Part-I

2013年12月23日Autogenous mills are so-called due to the self-grinding of the . ore: a rotating drum throws larger rocks of ore in a cascading .

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日For autogenous mills, like the dry Aerofall mills, MacPherson and Turner [7] established that the power consumption was a function of mill diameter and length.

Design of a typical Autogenous Mill: Part-II ResearchGate

2013年12月23日The drum is rotating with low speed (i.e. 16.37 RPM) inside the mill. offers a savings in capital and operating costs. The

Autogenous AGSAG Mills for Sale 911Metallurgist

The metallurgical advantages of autogenous milling are: (1) liberation at a coarser grind due to less cross grain breakage. This produces equivalent

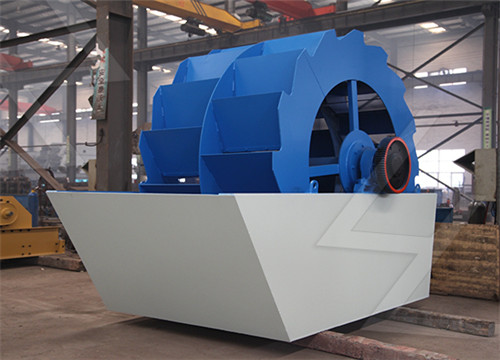

The study of the lining layer abrasing wear in the semi

autogenous grinding mills) are carried out with the obtaining of mathematical models of wear-abrasing of washing drum, gear gears of power drives (Figure 1), which account

Autogenous Grinding Mining Fundamentals AZoMining

Also, autogenous mills have grate discharges, so as to retain the coarse grinding media in the mill while dispatching the fine particles. The other benefits of using autogenous

Analyzing the Operation and Design of an Autogenous Mill Using

2020年1月29日A mill is a device that breaks solid materials into smaller pieces by grinding and crushing. Comminution is an important unit operation in many processes and there

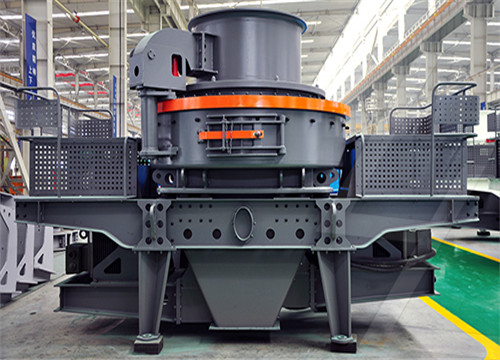

What is a Semi-Autogenous Mill? ballmillssupplier

A semi-autogenous mill is a type of grinding mill that uses grinding balls and ore or rock fragments as grinding media. The grinding is done by the impact of the rocks or ore

What is the Difference Between Tumbling Mill and Ball Mill?

Tumbling mills offer several advantages, including high capacity, low maintenance, and relatively low cost. However, they also have some disadvantages, such as high energy

Autogenous mills, semi-autogenous mills and ball mills for

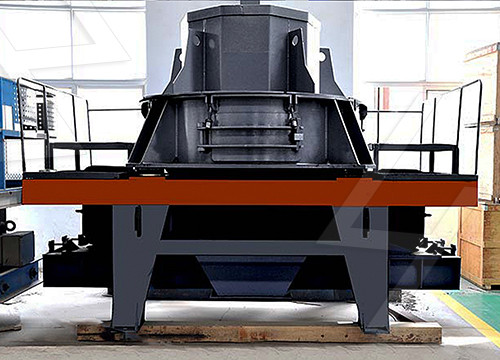

3 The design offers such benefits as: xElimination of castings and the structural risk associated with them. xFeed and discharge designed to process requirements rather

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日Some dry autogenous mills operating in Canada are 8.5 m in diameter and 1.5 m in length. These are known as Aerofall mills. The Cadia Hill (Australia) wet SAG mill is 12.2 m in diameter with a 20 MW motor and in 2004 was the largest diameter mill in operation in the world.

Autogenous mill and semi-autogenous mill Polysius

Autogenous (AG) and semi-autogenous (SAG) mills have been used for over 20 years for the coarse grinding of diverse ores (including gold, copper and iron ores). They offer advantages with regard to capital costs and operating expense compared to the secondary and tertiary crushers used in conventional size-reduction systems.

Study of the factors increasing the quality and productivity of drum

2018年11月7日In the presented stone attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. Th...

Autogenous mills, semi-autogenous mills and ball mills for

3 The design offers such benefits as: xElimination of castings and the structural risk associated with them. xFeed and discharge designed to process requirements rather than to restrictions imposed by trunnion bearings. xMinimised risk of feed blockage through short trunnions. xQuick accessibility to mill interior. xLighter weight and lower number of

What is a Semi-Autogenous Mill? ballmillssupplier

Autogenous mills are a type of semi-autogenous mill that does not use grinding media like steel balls or rods. Instead, they rely on the material itself to break down into smaller particles, typically using a large rotating drum filled with the material.

Study of the factors increasing the quality and productivity of

Abstract.In the presented attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. The factors, affecting the milling processare examined. Thefactors, related torequired energy for grinding: rotational speed of the drum,type of

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

Autogenous, Semi-Auto-Genous and Ball Mills For Wet and Dry

Ball mills, autogenous mills and semiautogenous mills from With the unique POLWELD® site welding concept for ThyssenKrupp Industrial Solutions with diameters above 8 m precise alignment and welding of the mill sections on site, ThyssenKrupp Industrial Solutions offers a favourably-priced and 11 m respectively and drive powers exceeding 22 MW are

Semi-Autogenous Wet Grinding Modeling with CFD-DEM

2021年2月26日The stone highlights the features of constructing a model of a wet semi-autogenous grinding mill based on the discrete element method and computational fluid dynamics. The model was built using Rocky DEM (v. 4.4.2, ESSS, Brazil) and Ansys Fluent (v. 2020 R2, Ansys, Inc., United States) software.

11.6 Portland Cement Manufacturing US EPA

1971年8月17日1 percent before or during grinding. Drying alone can be accomplished in impact dryers, drum dryers, paddle-equipped rapid dryers, air separators, or autogenous mills. However, drying can also be accomplished during grinding in ball-and-tube mills or roller mills. While thermal energy for drying

Small Ball Mill 911Metallurgist

The ball mill, an intermediate and fine-grinding device, is a tumbling drum with a 40% to 50% filling of balls. The material that is to be ground fills the voids between the balls. autogenous mills, or semi-autogenous mills. Regrind mills in mineral processing operations are usually ball mills, because the feed for these applications is

semi-autogenous mills 英中 Linguee词典

maintenance of the semi-autogenous grin ding ( SAG) mill in t he first. [...] quarter. mmg. mmg. 已處理礦石量受到礦石硬度以及 第一季度計 劃外進行 半自磨機 (SAG)維 護影 響。. mmg. mmg. ( e) Autogenous igni tion temperature.

Study of the factors increasing the quality and productivity of drum

In the presented stone attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. The factors, affecting the milling process are examined. The factors, related to required energy for grinding: rotational speed of the drum, type of the

Hammer Mill 86 Manufacturers, TradersSuppliers

Hammer Mill. Description. For grinding and processing of raw materials from agricultural and forestry products, as well as by-products and other materials, hammer mills are used in numerous industries. With many years of experience we manufacture the normal space hammer mill type 90 in four different grinding chamber widths.

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日Some dry autogenous mills operating in Canada are 8.5 m in diameter and 1.5 m in length. These are known as Aerofall mills. The Cadia Hill (Australia) wet SAG mill is 12.2 m in diameter with a 20 MW motor and in 2004 was the largest diameter mill in operation in the world.

Autogenous mill and semi-autogenous mill Polysius

Autogenous (AG) and semi-autogenous (SAG) mills have been used for over 20 years for the coarse grinding of diverse ores (including gold, copper and iron ores). They offer advantages with regard to capital costs and operating expense compared to the secondary and tertiary crushers used in conventional size-reduction systems.

Study of the factors increasing the quality and productivity of drum

2018年11月7日In the presented stone attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. Th...

Small Ball Mill 911Metallurgist

The ball mill, an intermediate and fine-grinding device, is a tumbling drum with a 40% to 50% filling of balls. The material that is to be ground fills the voids between the balls. The tumbling balls capture the particles in ball/ball or ball/liner events and load them to

Autogenous mills, semi-autogenous mills and ball mills for

3 The design offers such benefits as: xElimination of castings and the structural risk associated with them. xFeed and discharge designed to process requirements rather than to restrictions imposed by trunnion bearings. xMinimised risk of feed blockage through short trunnions. xQuick accessibility to mill interior. xLighter weight and lower number of

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

Study of the factors increasing the quality and productivity of

Abstract.In the presented attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. The factors, affecting the milling processare examined. Thefactors, related torequired energy for grinding: rotational speed of the drum,type of

(PDF) Autogenous and Semi-Autogenous Mills, 2015 Update

2015年1月1日Mills of 44 ’ (13. 41 m) diameter with 32 MW (42,900 HP) and Ball Mills of 30’ (9.14 m) in d iameter and 28 MW (37,500 HP). Single grinding lines will process 200,000 mtpd of ore and more.

Grinding Fundamentals PDF Mill (Grinding) Bearing

Autogenous mills use the feed material as the grinding media. The larger the particle the more energy can be imparted, and therefore the more impact breakage is likely. Thus, a coarse feed is important for AG milling.

Hammer Mill 86 Manufacturers, TradersSuppliers

Extremely robust, industrial hammer mills for target grain size of 0.5 mm. Standalone operation of preparatory stage for fine grinding. For batch operation or integration in lines for continuous production. Technical data Steel or stainless steel. Inlet 340 mm or 670 mm. Drive power 7.5 kW to 45 kW. Low-wearout hammers. Variable sieve inserts.

DEA1 Autogenous drum mill Google Patents

drum mill grinding autogenous conical Prior art date 1970-07-06 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Pending Application number DE

Study of the factors increasing the quality and productivity of drum

In the presented stone attention is paid to the ball mills, semi-autogenous and autogenous mills. The applications of mills are reviewed. The most used working regime of ball mills is described. The factors, affecting the milling process are examined. The factors, related to required energy for grinding: rotational speed of the drum, type of the

11.6 Portland Cement Manufacturing US EPA

1971年8月17日1 percent before or during grinding. Drying alone can be accomplished in impact dryers, drum dryers, paddle-equipped rapid dryers, air separators, or autogenous mills. However, drying can also be accomplished during grinding in ball-and-tube mills or roller mills. While thermal energy for drying