Closed Circuit Crushing Theory Ball Mill Suppliers By Acc

Closed circuit ball mill Basics revisited ScienceDirect

2013年4月1日The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to

Ball Mill Grinding Theory Crushing Motion/Action Inside

2017年4月28日Closed-circuit crushing is more desirable than open-circuit. The real advantage in closed-circuit crushing lies in the fact

Ball Mills Industry Grinder for Mineral Processing JXSC

2018年1月30日Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of

Ball Mill Close Circuits Ball Mill and Open Circuits Ball Mill

We are manufacturer and supplier of ball mills since 1980. 400 installations worldwide with closed and open circuits ball mill for cement, limestone, iron ore and coal. Ball Mill

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Open or Closed Circuit Crushing Mineral Processing

2016年2月29日In designing a closed-circuit crushing stage, the question of how much circulating load should be carried is a very important one. It not only has a direct bearing upon the capacity of the stage; it

Open And Closed Circuit Grinding Crusher Mills

Closed Circuit Cement Mills For Lime Stone Grinding Min. Order: 1 Set FOB Price: US $5000-80000 / Set Closed white cement finish grinding open circuit Crusher South

Batch Ball Mill for Open or Closed Circuit Grinding

Batch Ball Mill Effective volume: 0.4-71.2m3 Maximum charge: 0.1-40tons/time Motor power: 2.2-132kW Applications: Batch ball mill is used for fine grinding of new building materials, silicate products, quartz,

Closed Circle Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mill -China Henan Zhengzhou Mining Machinery Co.,Ltd. Ball Mill is made up of feeding part, discharging part composition and the separator flow grinding circle.

Closed circuit ball mill Basics revisited ScienceDirect

2013年4月1日The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to cyclone underflow, resulting in a classification efficiency of 50%. Ball mill crushing in closed circuit with screens Minesota school of mines experimental station. Bulletin

Mining and Mineral Processing Equipment Supplier ZJH minerals

2019年2月17日Ball Mill Manufacturers. Ball mill manufacturers (ZJH minerals) has the facilities and testing tools for mufacturing high quality ball mills. Bauxite beneficiation crushing commonly used three-stage one-closed circuit crushing process;Grinding and Classification: Grinding often adopts grid type ball mill with closed circuit [] March 3,

USING THE SMC TEST® TO PREDICT COMMINUTION

The closed circuit crusher distribution can be seen to be relatively steep compared with the open circuit crusher distribution and ball mill cyclone overflow. Also the open circuit distribution more closely follows the gradient of the cyclone overflow. If a ball mill circuit were to be fed 2 distributions, each with same P80

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

The two main objectives for a grinding process are: To liberate individual minerals trapped in rock crystals (ores) and thereby open up for a subsequent enrichment in the form of separation. To produce fines (or

THE BENEFITS OF HIGH CLASSIFICATION

2013年1月1日[Show full abstract] performances of these cement grinding technologies, industrial scale data were collected from HPGR-ball mill, VRM, Horomill and multi-chamber ball mill closed circuits.The

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日Prediction of crusher performance has been focused on, since crushing is a vital process for both industries. In this thesis a method for prediction of cone crusher performance is presented....

Ball Mill Eastman Rock Crusher

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized balls. Types of Ball Mill

Batch Ball Mill for Open or Closed Circuit Grinding

Batch Ball Mill. Effective volume: 0.4-71.2m3. Maximum charge: 0.1-40tons/time. Motor power: 2.2-132kW. Applications: Batch ball mill is used for fine grinding of new building materials, silicate products, quartz, feldspar, clay, nonferrous ore and other raw materials. Email: info@ballmillssupplier.

Open And Closed Circuit Grinding Crusher Mills

Cement Mills-Cement Mills Manufacturers, Suppliers and. Closed Circuit Cement Mills For Lime Stone Grinding Min. Order: 1 Set FOB Price: US $5000-80000 / Set Closed .

Comminution circuit bottlenecks How to increase plant

2019年3月25日SAG mills. Replacements are seldom done to SAG mills due to cost and also the constraints of other circuit equipment. Instead, often additional production lines are added. Also, if the bottleneck is the SAG mill, adding a pebble crusher can provide a small production boost (typically 5 to 10%). Ball mills. For ball mills, replacement is less

Closed Curcuit Crushers Crusher Mills, Cone Crusher, Jaw Crushers

closed circuit crusher system mining application. New KPI-JCI Track-Mounted Closed-Circuit The GT200CC features the Kodiak 200+ cone crusher, which was originally the GT200CC will provide the most efficient

ball mill suppliers by acc razoriteolivedale.co.za

Ball Mill Suppliers By Acc 24528. Home ball mill suppliers by acc 24528 ; ball mill. Processing capacity: 183-408t/h. Feeding size: ≤23mm. Appliable Materials: cement,silicate,new-type building material,refractory material,ore,construction rubbish etc. All

Crusher an overview ScienceDirect Topics

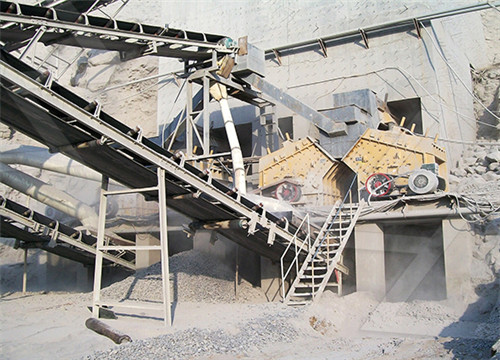

These crushers are invariably operated in closed circuit. The final product sizes are fine, medium or coarse depending on the closed set spacing, the configuration of the crushing chamber and classifier performance, which is always installed in parallel.

Closed circuit ball mill Basics revisited ScienceDirect

2013年4月1日The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to cyclone underflow, resulting in a classification efficiency of 50%. Ball mill crushing in closed circuit with screens Minesota school of mines experimental station. Bulletin

Mining and Mineral Processing Equipment Supplier ZJH minerals

2019年2月17日Ball Mill Manufacturers. Ball mill manufacturers (ZJH minerals) has the facilities and testing tools for mufacturing high quality ball mills. Bauxite beneficiation crushing commonly used three-stage one-closed circuit crushing process;Grinding and Classification: Grinding often adopts grid type ball mill with closed circuit [] March 3,

USING THE SMC TEST® TO PREDICT COMMINUTION

The closed circuit crusher distribution can be seen to be relatively steep compared with the open circuit crusher distribution and ball mill cyclone overflow. Also the open circuit distribution more closely follows the gradient of the cyclone overflow. If a ball mill circuit were to be fed 2 distributions, each with same P80

THE BENEFITS OF HIGH CLASSIFICATION

2013年1月1日[Show full abstract] performances of these cement grinding technologies, industrial scale data were collected from HPGR-ball mill, VRM, Horomill and multi-chamber ball mill closed circuits.The

Comminution circuit bottlenecks How to increase

2019年3月25日In the case of a SAG and ball mill circuit either machine could be the bottleneck. Corrective actions depend on both circuit and how much ore variation is experienced. For example, when SAG limited and if

Ball Mill Eastman Rock Crusher

Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit. The feed materials can be dry or wet, they are

Batch Ball Mill for Open or Closed Circuit Grinding

Batch Ball Mill. Effective volume: 0.4-71.2m3. Maximum charge: 0.1-40tons/time. Motor power: 2.2-132kW. Applications: Batch ball mill is used for fine grinding of new building materials, silicate products, quartz,

Solved A two-stage grinding circuit, with a crusher in open

Question: A two-stage grinding circuit, with a crusher in open circuit and a ball mill in closed circuit, is used to grind 30 tonnes per hour of ore (solids flow rate). The circuit layout is shown in Figure below. Sampling of the circuit gave the following information: Stream %solids by weight % [-100 um] Crusher feed 80 4 Crusher discharge 80 Ball

Open And Closed Circuit Grinding Crusher Mills

Cement Mills-Cement Mills Manufacturers, Suppliers and. Closed Circuit Cement Mills For Lime Stone Grinding Min. Order: 1 Set FOB Price: US $5000-80000 / Set Closed .

Closed Curcuit Crushers Crusher Mills, Cone Crusher, Jaw Crushers

Closed-Circuit type: The Closed-Circuit type mobile crusher takes one crushing unit as the main part and adopts the single-machine configuration. Portable Closed-Circuit Crushing Plant parameter model: Screen model: crusher model: Conveyor model under screen: Conveyor model over screen: Belt conveyor model: capacity (t/h) Power (kw)

Ball Mill RETSCH powerful grinding and homogenization

The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. CoolingHeating Mixer Mill MM 500 control Material feed size*: <= 10 mm Final fineness*: ~ 0.1 µm Vibrational frequency: 3 30 Hz (180 -1800 min-1) Product details Nanoscale Grinding

ball mill suppliers by acc razoriteolivedale.co.za

Ball Mill Suppliers By Acc 24528. Home ball mill suppliers by acc 24528 ; ball mill. Processing capacity: 183-408t/h. Feeding size: ≤23mm. Appliable Materials: cement,silicate,new-type building material,refractory material,ore,construction rubbish etc. All

Size Reduction and Energy Requirement ScienceDirect

2016年1月1日For a rod mill–ball mill circuit, do not apply a mill diameter correction for the ball mill. If the rod mill feed is produced by open circuit crushing, use a factor of 1.2 for the rod mill stage only. If the rod mill feed is 80% passing 12 mm or less (e.g. from a closed circuit crusher) do not apply a rod mill efficiency factor.

- 上海外资圆锥破碎机生产生产破碎

- 煤炭排矸设备

- 重庆腻子粉生产厂

- Sand Washer Machine For Sale Libya

- Crushing Plant Aggregate Sand And Gravel Philippines

- 时产1000吨雷蒙粉磨机

- 超高功率电电极碎

- Want To Sell Crusher Parts

- 中煤新疆露矿

- Wet Grinder Small Stores In Coimbatore

- Crushing Sale Horizontal Crushing Equipments In India

- HP500圆锥破碎机平衡圈

- 制砂机比较

- Stone Crusher Business Subsidies Available India

- 155液压破碎锤充多少氮气