Basic Principle Of Cone Crusher

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening,

进一步探索

Operation Manual For Cone CrusherCone Crusher VS Gyratory Crusher JXSC MineWhat is the working principle of the Cone Crusher? QuoraThe pros and cons of cone crusher applications QuarryA Detailed Overview of Cone Crushers and What You Nee根据热度为您推荐•反馈

Cone Crusher Working Principle Animation Engineering Intro

2012年8月15日Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. Cone crusher parts It

Cone Crusher an overview ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and

进一步探索

Cone Crusher Working Principle Animation Engineering (PDF) Cone Crusher Performance ResearchGate根据热度为您推荐•反馈

A Detailed Overview of Cone Crushers and What You

2020年6月3日Many cone crusher manufacturers use the Symons Principle to produce more powerful and efficient crushers. Based on

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日A cone crusher is a core component of the particle crushing process employed in various industrial sectors [1]. Capacity is

Cone Crusher Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

How does cone crusher work? YouTube

2020年12月30日Cone crushers are popular hard stone crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in sec...

Principle of a cone or gyratory crusher. ResearchGate

basic operating principle of a cone crusher is shown in Figure 4. The properties, i.e. size distribution and quality parameters, of the product leaving the crusher are a result of the...

Types of Crushers: What You Need to Know Machinery Partner

A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the

Cone Crusher an overview ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other. The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles.

How A Cone Crusher Works McLanahan

How It Works Videos. McLanahan Cone Crushers are compression type crushers that deliver a 4:1 to 6:1 reduction ratio. Based on the the Symons cone crushing principle and improved after years of field testing,

A Detailed Overview of Cone Crushers and What

2020年6月3日Many cone crusher manufacturers use the Symons Principle to produce more powerful and efficient crushers. Based on this principle, each rotation of the mantle is timed in a way so that the thrust

Gyratory and Cone Crusher ScienceDirect

2016年1月1日The secondary crushers are also designed on the principle of gyratory crushing, but the construction details vary. A cone crusher of height 2.1 m, open side feed opening 30.4 cm and a closed set at 5.1 cm gyrated at 480 rpm to crush quarry limestone scalped at 20.3 cm opening screen. The crusher was expected to crush at the

Cone Crushers MobileHigh Productivity Finlay

The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides large reduction ratios and an excellent cubical shaped end product. The robust design of the plant enables it to accept an all in feed and makes it particularly suitable when

Hydraulic Cone Crusher Working Principle Animation YouTube

2018年2月26日Types of cone crushers used in aggregates production, mining operations, and recycling applications. how to select the right one https://bit.ly/3d509vR =====...

Principle of a cone or gyratory crusher. ResearchGate

basic operating principle of a cone crusher is shown in Figure 4. The properties, i.e. size distribution and quality parameters, of the product leaving the crusher are a result of the...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by liberating...

Working Principle of Crushers Mineral Processing

2016年2月17日Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1.” Note that the length of

Gyratory Crusher l Introduce, Working Principle

Gyratory Crusher VS Cone Crusher. 1. The two cone shapes of the gyratory crusher are steeply inclined. The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase

Fundamental Principles Of Cone Crusher Crusher Mills, Cone Crusher

Cone crusher working principle in China.This page is about how cone crusher works. if you want to know the working principles of a cone crusher Basalt Crusher Stone Crushing Plant is a basic crushing plant that is used for crushing stones or

The Basic Principle of A Cone Crusher Is Depicted in Figure 9 and

The Basic Principle of a Cone Crusher is Depicted in Figure 9 and Described Here Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. cone crusher ,cs

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日Cone Crusher DUST SEAL The dust seal is a plastic ring suspended in a housing from the head center and encircling the dust collar. It is designed to accommodate the vertical adjustment and the gyrating and rotating motion of the head. All wearing parts are replaceable.

CS440 CS430 Crusher CS Series Cone Mining Machinery and

CS440 CS430 Crusher CS Series Cone Mining Machinery and Equipment, Find Details and Price about CS Hydraulic Cone Crusher CS Hydraulic Crusher Machine Price from CS440 CS430 Crusher CS Series Cone Mining Machinery and Equipment Shenyang Huayue Brilliant MachineryEquipment Co., Ltd.

Cone Crusher an overview ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are parallel to each other. The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles.

How A Cone Crusher Works McLanahan

How It Works Videos. McLanahan Cone Crushers are compression type crushers that deliver a 4:1 to 6:1 reduction ratio. Based on the the Symons cone crushing principle and improved after years of field testing,

Gyratory and Cone Crusher ScienceDirect

2016年1月1日The secondary crushers are also designed on the principle of gyratory crushing, but the construction details vary. A cone crusher of height 2.1 m, open side feed opening 30.4 cm and a closed set at 5.1 cm gyrated at 480 rpm to crush quarry limestone scalped at 20.3 cm opening screen. The crusher was expected to crush at the

Cone Crushers MobileHigh Productivity Finlay

The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that provides large reduction ratios and an excellent cubical shaped end product. The robust design of the plant enables it to accept an all in feed and makes it particularly suitable when

What is the working principle of the Cone Crusher?

Answer (1 of 2): AIMIX cone crusher is a type of compression machine. The cone crusher has a smaller crushing chamber. Therefore, break the rocks by tightening them between the rotating spindles. In addition, these

Principle of a cone or gyratory crusher. ResearchGate

basic operating principle of a cone crusher is shown in Figure 4. The properties, i.e. size distribution and quality parameters, of the product leaving the crusher are a result of the...

Hydraulic Cone Crusher Working Principle Animation YouTube

2018年2月26日Types of cone crushers used in aggregates production, mining operations, and recycling applications. how to select the right one https://bit.ly/3d509vR =====...

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日Cone Crusher DUST SEAL The dust seal is a plastic ring suspended in a housing from the head center and encircling the dust collar. It is designed to accommodate the vertical adjustment and the gyrating

The Basic Principle of A Cone Crusher Is Depicted in Figure 9 and

The Basic Principle of a Cone Crusher is Depicted in Figure 9 and Described Here Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. cone crusher ,cs

Gyratory Crusher l Introduce, Working Principle

The two cone shapes of the gyratory crusher are steeply inclined. The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase the need for feeding ore. Nevertheless, cone

Fundamental Principles Of Cone Crusher Crusher Mills, Cone Crusher

Cone crusher working principle in China.This page is about how cone crusher works. if you want to know the working principles of a cone crusher Basalt Crusher Stone Crushing Plant is a basic crushing plant that is used for crushing stones or

Working Principle of Cone CrusherHammer Crusher

2016年8月15日Cone crusher has the key part like bracket, movable cone, fixed cone and eccentric sleeve. Upgrades on Working Principle of Cone Crushers Sep 17, 2016 To Upgrade Linear Boards of Jaw Crusher

Types of Rock Crushers Quarry Crushing Equipment Kemper

Cone crushers can accept medium-hard to very hard and abrasive feeds that might be dry or wet, though not sticky (whereas gyratory crushers are better at handling softer, dryer feeds). Their output will be a relatively cubical product,

A review of modeling and control strategies for cone

This work opens with a brief review of the mechanical principles of cone crushers. Then, in the following sections, works available in the cone crusher literature, ranging from 1972 to 2020, are categorized with respect to the model structure and control strategy implementation. Remarks about the most important contributions of each work are

- Cobalt Ore Milling Equipment Manufacturer

- 石粉的加工球磨机-矿石设备厂家价格

- Coal Mining Equipment In South Africa

- 采石厂税费

- Jaw Crusher Prototype

- 厂家直销方案低价粉煤灰

- 二手机制砂设备转让

- 高效制砂机哪里有卖

- Larger China Advanced Bauxite Crusher Mill Invest Cost In Thailand

- 球磨机出料口

- Short Head Cs Cone Crushing Equipment Parts

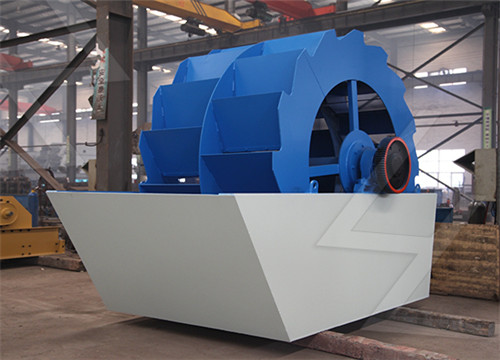

- High Tech Competitive Bucket Sand Washing Machine With Good Quality

- Arrangement Of Crushing Plant In Usa

- 浙江石英砂厂

- Stone Breaking Machine Impact Mining Mill Rock Breaking Machine