Working Of Pitman In Double Toggle Impact Crusher

Jaw Crushers McLanahan

A toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw. The toggle plate is designed to perform like a fuse and protect the crusher in the

Different types of crushers for distinctive needs Metso Outotec

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher.

Difference Between SingleDouble Toggle Jaw Crusher

2014年9月20日In a double toggle jaw crusher, the eccentric is located behind the swinging jaw. This has two main effects, it keeps the

How Does a Jaw Crusher Work Jaw Crusher Kemper

2022年6月8日Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher,

USA1 Pitman of a jaw crusher, jaw crusher

2011年8月18日A pitman of a jaw crusher comprising an upper part, which comprises an upper supporting point for supporting the pitman in the body of the jaw crusher, and a

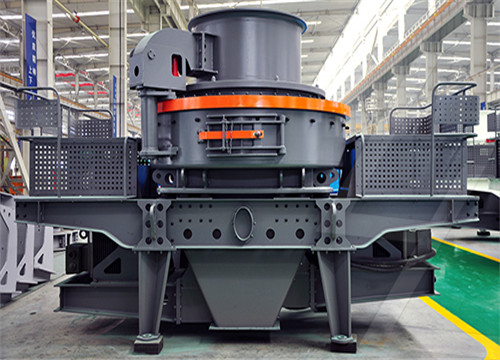

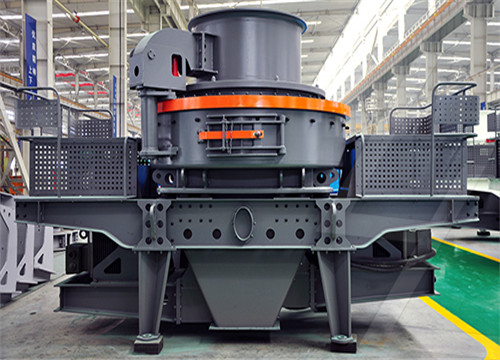

Impact crusher structure, working principle and features

2021年9月2日This kind of crusher is to make use of expanding the working angle of the rotor and adopting the principle of splitting cavity (crushing cavity) to focus on impact crushing, which makes the two

Blake Jaw Crusher Mineral ProcessingMetallurgy

2016年1月15日The actuating mechanism consists of the eccentric-shaft (also supported in bearings in the sides of the frame), the pitman, and the pair of toggles, which span from swing jaw to pit-man, and from pitman

Jaw Crusher Working Principle StudiousGuy

A single toggle jaw crusher has a better capacity than a double toggle jaw crusher. Double Toggle Jaw Crusher. A double toggle jaw crusher consists of two shafts and

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more

Gyratory Crusher an overview ScienceDirect Topics

Crushing takes place by the impact of material pieces with the high speed moving hammers and by contact with breaker plates. A cylindrical grating or screen is placed beneath the rotor. Materials are reduced to a size small enough to pass through the openings of the grating or screen.

(PDF) Optimum design and analysis of (the) swinging

2010年4月30日Based on the analysis of the liner movement and the crushing parameters, force distribution along the swing jaw plate is obtained. The job is helpful for a design of new prototype of this kind of...

How Does a Jaw Crusher Work Jaw Crusher

Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake ), have long been the standard used for crushing hard and abrasive rocks,

What are double-toggle jaw crushers for the hardest and Quora

Answer: Double-toggle jaw crushers are equipped with a system of toggle levers, which are moved up and down by a pitman via an eccentric shaft. The alternating stretching and bending movements cause an oscillating motion of the swing jaw. Since the material to be crushed falls down by gravitatio...

Blake Jaw Crusher Mineral ProcessingMetallurgy

2016年1月15日The actuating mechanism consists of the eccentric-shaft (also supported in bearings in the sides of the frame), the pitman, and the pair of toggles, which span from swing jaw to pit-man, and from pitman

Impact crusher structure, working principle and

2021年9月2日This kind of crusher is to make use of expanding the working angle of the rotor and adopting the principle of splitting cavity (crushing cavity) to focus on impact crushing, which makes the two

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than with the double toggle crusher [10]. Moreover, the single toggle crusher is taking over most new applications due to lower cost and

Knowing the Basics Leads to Better Care Timken Company

2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high start-up torque, shock loads and vibration demand high-performing anti-friction bearings that can operate reliably with minimal heat generation. Jaw Crushers Most operations prefer jaw crushers for primary crushing. A large feed

Jaw Crusher Working Principle StudiousGuy

A double toggle jaw crusher consists of two shafts and two toggle plates. The first shaft is the pivoting shaft on the top of the crusher, whereas the other shaft is the eccentric shaft that is used to drive both the toggle plates. Advantages of a Jaw Crusher 1. Jaw crushers are comparatively inexpensive. 2.

Eccentric Shaft an overview ScienceDirect Topics

Because of the constant rotary motion of the sample container, the cylindrical weight and annular ring exert a constant pressure on the container wall, and coal particles caught in between are crushed to finer sizes. A fixed amount of energy was expended on a sample of given mass of uniformly sized material.

Jaw Crusher Plants ELRUS Aggregate Equipment

The movable jaw (Pitman) is attached to an eccentric shaft that causes it to move in a reciprocating motion. Rock enters the crushing chamber from the top and moves through the chamber, which gets narrower as it gets deeper,until it is caught between the two jaws, where it is squeezed until it fractures. Typical applications: Stone Crushing

Jaw Crushers LinkedIn

2017年1月16日The seating (234) of the rear toggle plate (239) is fixed to the crusher frame ; the bottom of the swing jaw (214) is therefore pushed forward each time the pitman rises, a tension rod (245)...

Study on Liner wear in Single Toggle Jaw Crushers: A Review

The Blake jaw crusher was originally designed by Eli Whit-ney Blake in 1857 [3]. The Blake jaw crushers are of two types: double toggle Blake and single toggle Blake as shown in Fig-ure 2. The double toggle machine, though robust and power consuming, can crush very hard rocks without abrasive wear.

Cone Crusher an overview ScienceDirect Topics

The moving jaw dies are mounted on a pitman that has a reciprocating motion. The jaw dies must be replaced regularly due to wear. Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher.

Eccentric Shaft an overview ScienceDirect Topics

Because of the constant rotary motion of the sample container, the cylindrical weight and annular ring exert a constant pressure on the container wall, and coal particles caught in between are crushed to finer sizes. A fixed amount of energy was expended on a sample of given mass of uniformly sized material.

What are double-toggle jaw crushers for the hardest and Quora

Answer: Double-toggle jaw crushers are equipped with a system of toggle levers, which are moved up and down by a pitman via an eccentric shaft. The alternating stretching and bending movements cause an oscillating motion of the swing jaw. Since the material to be crushed falls down by gravitatio...

Impact crusher structure, working principle and features

2021年9月2日This kind of crusher is to make use of expanding the working angle of the rotor and adopting the principle of splitting cavity (crushing cavity) to focus on impact crushing, which makes the two rotors give full play to coarse crushing and fine crushing.

Knowing the Basics Leads to Better Care Timken Company

2 Crusher Bearings: Knowing the Basics Leads to Better Care Compression Crushers In compression crushers, high start-up torque, shock loads and vibration demand high-performing anti-friction bearings that can operate reliably with minimal heat generation. Jaw Crushers Most operations prefer jaw crushers for primary crushing. A large feed

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than with the double toggle crusher [10]. Moreover, the single toggle crusher is taking over most new applications due to lower cost and

Single Toggle vs Double Toggle Jaw Crusher JXSC Machine

2019年5月25日Contact Now +86-. Published time:25 May 2019. Crusher machines play an important role in the mines, metallurgy, building materials, quarrying, recycling, chemical and so on industries. According to the difference of structure and working principle, the rock crushers are mainly divided into jaw crusher, cone crusher,

Study on Liner wear in Single Toggle Jaw Crushers: A Review

The Blake jaw crusher was originally designed by Eli Whit-ney Blake in 1857 [3]. The Blake jaw crushers are of two types: double toggle Blake and single toggle Blake as shown in Fig-ure 2. The double toggle machine, though robust and power consuming, can crush very hard rocks without abrasive wear.

Large Industrial Rock Crushers 911Metallurgist

Our Large Industrial Rock Crushers employ two planer-crushing surfaces set at a small angle to each other and convergent downward. One plane is fixed and the other is pivoted either top or bottom allowing a reciprocating motion when pushed by a pitman-toggle arrangement activated by an eccentric drive. The 3 common variations of the jaw

Jaw Crusher Plants ELRUS Aggregate Equipment

The movable jaw (Pitman) is attached to an eccentric shaft that causes it to move in a reciprocating motion. Rock enters the crushing chamber from the top and moves through the chamber, which gets narrower as it gets deeper,until it is caught between the two jaws, where it is squeezed until it fractures. Typical applications: Stone Crushing

P&Q University Lesson 7- CrushingSecondary Breaking

2019年9月2日As the name implies, the horizontal-shaft impact (HSI) crusher has a shaft that runs horizontally through the crushing chamber, with a rotor that turns hammers or blow bars. It uses the high-speed impacting force of the turning blow bars hitting and throwing the stone to break the rock.

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.