Reason For Continuous Development Of Cone Crusher

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive.

进一步探索

Operation Manual For Cone CrusherCone Crusher VS Gyratory Crusher JXSC Mine根据热度为您推荐•反馈

A Detailed Overview of Cone Crushers and What You Need to Know

2020年6月3日For this reason, companies typically deploy cone crushers as part of a more extensive system of crushing equipment. A first-stage

Cone Crusher Explained saVRee

IntroductionCone Crushers HistoryPurpose of CrushersCrusher TypesCone Crusher Components

A crusher is a machine designed to reduce the size of large rocks to smaller rocks,gravel,sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue)material. Waste material can be discarded or recycled allowing...

History of the Cone Crusher Mellott

2022年10月27日Posted on October 27, 2022 by Mellott. 27. Oct. The cone crusher, introduced by the Symons brothers in the 1920s, wasn’t quite a big deal when it first

Reason for Continuous Development of Cone Crusher

Cone crusher is a kind of crusher which can actually create more value for the user. In the 21st century, the concept of low carbon also needs this kind of high efficient crusher.

Causes of Development of Cone Crusher xyxy1314ww

2014年6月23日Cone crusher is a kind of crusher which can actually create more value for the user. In the 21st century, the concept of low carbon also needs this kind of high

Development of wear model for cone crushers

2006年8月30日The geometry of the crushing chamber is crucial for the performance. Due to wear the geometry of the liners will change, and hence the crusher performance will

Continuous Improvements on customers TC51 Cone Crusher

2018年7月20日The material change on the TC51 cone crusher liners saw an increase in liner life from 34 days to 39 days. Stage Two Profile Change. Following on from this

Causes of Development of Cone Crusher Research Paper

The superior design and the perfect performance of the cone crusher is the root reason of its continuous development. 1 Ratio of reduction is large and the production efficiency

Cone Crusher an overview ScienceDirect Topics

The flatter cone angles help to retain the particles longer between the crushing surfaces and therefore produce much finer particles. To prevent damage to the crushing surfaces, the concave or shell of the crushers is held in place by strong springs or hydraulics which yield to permit uncrushable tramp material to pass through.

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

A Detailed Overview of Cone Crushers and What

2020年6月3日Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics

Cone Crusher Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead

Development of wear model for cone crushers ScienceDirect

2006年8月30日A model to predict the worn geometry of cone crushers was previously developed. In that model there was some disagreements between predicted and measured geometry and several effects were suggested to explain the discrepancy in the model. In this study the effect of shear forces along the crushing surfaces was implemented in the model.

In order to improve the performance of hydraulic cone crusher

2017年6月29日With the continuous development of technology, hydraulic cone crusher performance has been significantly improved, cone crusher from a single hydraulic cone crusher model to the development of

Development of wear model for cone crushers Semantic Scholar

The purpose of crushing equipment is to reduce the size of aggregates. Minerals have good compressive strength, but they are relatively weak in tension. Most of the equipment crushes the rock by Expand View 1 excerpt, cites methods Save Alert Influence of particle size on wear rate in compressive crushing

Continuous Improvements on customers TC51 Cone Crusher Performance

2018年7月20日The material change on the TC51 cone crusher liners saw an increase in liner life from 34 days to 39 days. Stage Two Profile Change. Following on from this first stage, H-E Parts advised Western Areas that development of a custom liner profile for their TC51 cone crusher liners would provide significant benefits.

Causes of Development of Cone Crusher Research Paper

The superior design and the perfect performance of the cone crusher is the root reason of its continuous development. 1 Ratio of reduction is large and the production efficiency is high. Cone crusher combines a higher speed and the stroke, which enhances the rated power and the carrying ability of the cone crusher.

Development of wear model for cone crushers Request PDF

2006年8月1日Abstract. Cone crushers are used in the aggregates and mining industries to crush rock material. A model to predict the worn geometry of cone crushers was previously developed. In that model there

Cone Crushers — SRP

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

Cone Crushers: The Suppliers’ Perspective EMJ

The company’s current cone-crusher portfolio includes five SBS models, with power requirements ranging from 200 to 600 hp, and three SBX models (300, 400 and 500 hp). SBS cone crushers can handle both coarse and fine crushing from secondary to fourth-stage applications, while the SBX models are designed for extra-coarse secondary

CORE Aggregating the world’s open access research s

CORE Aggregating the world’s open access research s

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

A Detailed Overview of Cone Crushers and What

2020年6月3日Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics

11.19.2 Crushed Stone Processing and Pulverized Mineral

Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 2.5 to 10 centimeters (1 to 4 inches). The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for the last crushing step.

Development of wear model for cone crushers ScienceDirect

2006年8月30日A model to predict the worn geometry of cone crushers was previously developed. In that model there was some disagreements between predicted and measured geometry and several effects were suggested to explain the discrepancy in the model. In this study the effect of shear forces along the crushing surfaces was implemented in the model.

In order to improve the performance of hydraulic cone crusher

2017年6月29日With the continuous development of technology, hydraulic cone crusher performance has been significantly improved, cone crusher from a single hydraulic cone crusher model to the development of

Development of wear model for cone crushers Semantic Scholar

The purpose of crushing equipment is to reduce the size of aggregates. Minerals have good compressive strength, but they are relatively weak in tension. Most of the equipment crushes the rock by Expand View 1 excerpt, cites methods Save Alert Influence of particle size on wear rate in compressive crushing

Continuous Improvements on customers TC51 Cone Crusher Performance

2018年7月20日The material change on the TC51 cone crusher liners saw an increase in liner life from 34 days to 39 days. Stage Two Profile Change. Following on from this first stage, H-E Parts advised Western Areas that development of a custom liner profile for their TC51 cone crusher liners would provide significant benefits.

Development of wear model for cone crushers Request PDF

2006年8月1日Abstract. Cone crushers are used in the aggregates and mining industries to crush rock material. A model to predict the worn geometry of cone crushers was previously developed. In that model there

Causes of Development of Cone Crusher Research Paper

The superior design and the perfect performance of the cone crusher is the root reason of its continuous development. 1 Ratio of reduction is large and the production efficiency is high. Cone crusher combines a higher speed and the stroke, which enhances the rated power and the carrying ability of the cone crusher.

Cone Crushers — SRP

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

Cone Crushers: The Suppliers’ Perspective EMJ

The company’s current cone-crusher portfolio includes five SBS models, with power requirements ranging from 200 to 600 hp, and three SBX models (300, 400 and 500 hp). SBS cone crushers can handle both coarse and fine crushing from secondary to fourth-stage applications, while the SBX models are designed for extra-coarse secondary

CORE Aggregating the world’s open access research s

CORE Aggregating the world’s open access research s

Wear Resistant Components Development of Crusher

2018年9月5日It is called the first generation wear resistant material because it is used as the toothed plate of jaw crusher, movable cone of cone crusher, fixed cone and hammer. With the development of crushing machine, more and more problems emerge one after another. For example, the enlargement of crushing field, the requirement for equipment

- 5000目云母磨粉机

- 混凝土矿矿山设备

- China Top Brand Manganese Ore Magnetic Separator

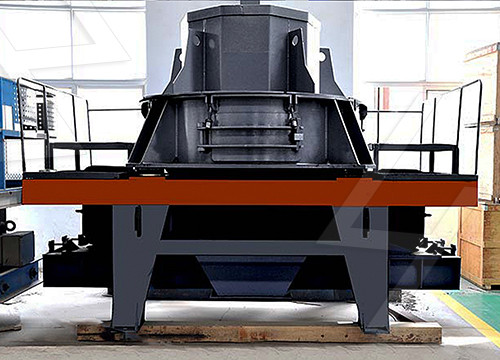

- 主轴式冲击破碎机

- 圆锥破碎机动画

- Competitive Hot Sale In Argentina Linear Vibrating Feeder

- 雷蒙机系列中相对较大的

- 石灰粉一般哪里有卖

- 北京金海鹰双腔回转破碎机

- 大理石开采要办许可证吗

- 60900破碎机尺寸

- High Efficiency Ball Grinder Mill Ball Grinder Machine For Mining Manufacture

- 印江对辊破碎机

- 大型液下泵轴承安装方式

- 建筑垃圾价格