Quotation For Operation Maintenance Of Crusher Plant

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour

Understanding three different types of crusher maintenance

PreventivePredictiveReactiveBenefits from A well-elaborated Maintenance PlanIt has been well documented for years that if preventive and predictive maintenance is ignored, the rock crusher will experience poor on-line availability, incredibly high operating costs and a shortened life span. Implementing a preventive and predictive maintenance program is a key factor in extending or maximizing your crusher performance. Some

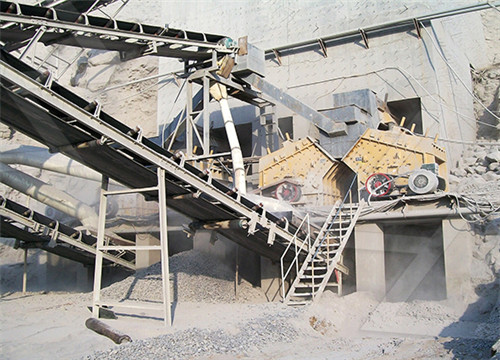

Stone Crusher Plant Operations and Maintenance ore

Operations of stone crusher plant 1. Make a rigorous testing before starting stone crusher. 2. Check the lubrication system regularly, when the stone crusher system is running. 3. Regularly examine the operation

Crushing Plant Installation, Operation and Maintain JXSC

To ensure higher production efficiency and longer service life, plant manufacturers must do a good job of maintenance. 1. Dearing

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation

Guidelines for Management Crushing and Screening

4.0 CRUSHING A. The hazards involved with blockages, dangerous moving parts, objects being ejected from crushers and maintenance tasks all need careful management. 4.1

Roll crusher installation, operation and maintenance

2021年8月23日2. Maintenance of the roll crusher. (1) Roll crushers require frequent maintenance of the roll surface while in operation. (2) Smooth roll crushers are

HSE Quarries Safe operation and use of mobile jaw

Isolation of motive power to the crusher and associated plant procedure in operation at the site ; Clear the area of all personnel ; Notify the site manager of the stalled crusher ; If,

Crushing Plant Startup SequenceProcedure

2016年1月26日Normal Crushing Plant Operation After the crushing plant has been brought up to normal operating conditions the operator should attempt to even out the feed to the jaw crusher to the design

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

Preventive crusher and screen maintenance Metso

Preventive maintenance technology explained with Metso Metrics. Metso Metrics technology for aggregates customers helps monitor, maintain and manage clients’ assets. Connected equipment is ensured by many

Crusher Maintenance Screening Equipment

Our factory and MSHA trained service team can come to your site, inspect our crushers and screens, train your employees on how to maintain equipment and replace parts or replace parts for you. Simply contact

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

OPERATION AND MAINTENANCE PLAN Engineering Division

1.1 Operation and Maintenance Plan Purpose An Operations and Maintenance (O&M) Plan (referred to in this document as the Plan) is the most important reference for management of the [insert dam name] [insert NID No.]. The Plan will describe the components and will outline the operation, inspection and maintenance

Guidelines for Management Crushing and Screening final feb10

4.0 CRUSHING A. The hazards involved with blockages, dangerous moving parts, objects being ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task. Blockage incidents can be greatly

HSE Quarries Safe operation and use of mobile jaw crushers

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the risk of large pieces of feed material moving and...

Tips for designing an efficient crushing and

2013年4月4日Hammermills are common in cement plants, where the top size of the primary crusher output must be a certain size for the next operation. Reduction ratios for this machine are typically 20:1.

Service Provider of Engineering ConstructionOperationMaintenance

B N Infrastructure Service Provider of Engineering Construction, OperationMaintenance Of Crusher PlantsQuarryingMining Works from Pune, Maharashtra, India

Plant Maintenance Resource Center Industrial Maintenance

Plant Maintenance Resource Center Industrial Maintenance information

Plant Maintenance Services, Plant Operation Maintenance in

Plant Maintenance Services Providers in Varanasi, प्लांट मेंटेनेंस सर्विस सर्विस प्रोवाइडर, वाराणसी, Uttar Pradesh. Get contact details and address of Plant Maintenance Services, Plant Operation Maintenance, Sugar Plant Maintenence firms and companies in Varanasi

Factors affecting the performance of crushing plant operations

2014年1月1日Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable development. Since the crushing plants are operated under...

My Plant Planner Metso Outotec

CrushingScreening 2 stages Primary and secondary crushers in a closed plant Excavate and transfer the raw material into a plant. Material is reduced in a jaw crusher. Material is screened either to the end-product pile or to a crusher to further reduction. Material is further reduced in a cone crusher. The end-product of your plant.

Crusher Plant Operation Quotation miejskaprzystan.net.pl

Quotation for operation maintenance of crusher plant. Mini cement plant quotation results 1 40 of 92798 cement plant operations 79-3 i summary this profile envisages the establishment mini cement plant project cost ore crusher plant chapter 14 canola council

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

Preventive crusher and screen maintenance Metso

Data shown for the machines are operating hours, fuel/power consumption, upcoming maintenance events, maintenance log, alarm log, parameter changes and machine location. If belt scales are installed, then it’s also

Crusher Maintenance Screening Equipment

Our factory and MSHA trained service team can come to your site, inspect our crushers and screens, train your employees on how to maintain equipment and replace parts or replace parts for you. Simply contact

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

OPERATION AND MAINTENANCE PLAN Engineering Division

1.1 Operation and Maintenance Plan Purpose An Operations and Maintenance (O&M) Plan (referred to in this document as the Plan) is the most important reference for management of the [insert dam name] [insert NID No.]. The Plan will describe the components and will outline the operation, inspection and maintenance

Tips for designing an efficient crushing and

2013年4月4日Hammermills are common in cement plants, where the top size of the primary crusher output must be a certain size for the next operation. Reduction ratios for this machine are typically 20:1.

B.N. INFRASTRUCTUREENGINEERS

1 At Udaipur Five Stage Crushing Plant Operation work is in Progress. Client is Balajee InfratechConstruction Pvt. Ltd. Main Client is IRB Infrastructuredevelopers Ltd.. 2 At Aruna Medium Dam, Gagan bawada, Maharashtra from 2010 to till now, for Client M/s Mahalakshmi Infraprojects, Puzollana make 120 TPH Crushing Plant Operation

Service Provider of Engineering ConstructionOperationMaintenance

B N Infrastructure Service Provider of Engineering Construction, OperationMaintenance Of Crusher PlantsQuarryingMining Works from Pune, Maharashtra, India

crusher/sbm crushing plant operations and maintenance

Contribute to yunan88/crusher development by creating an account on GitHub.

Plant Maintenance Resource Center Industrial Maintenance

Plant Maintenance Resource Center Industrial Maintenance information

Plant Maintenance Services, Plant Operation Maintenance in

Stp And Etp Operation Maintenance Services 1- ETP may be a system that removes toxic and non-toxic material from water and making it usable for various purposes. STP unit removes contaminants from municipal wastewater or household sewage. 2- ETP is employed in industrial areas whereas STP cleanses household water.

Crusher Plant Operation Quotation miejskaprzystan.net.pl

Quotation for operation maintenance of crusher plant. Mini cement plant quotation results 1 40 of 92798 cement plant operations 79-3 i summary this profile envisages the establishment mini cement plant project cost ore crusher plant chapter 14 canola council

My Plant Planner Metso Outotec

CrushingScreening 2 stages Primary and secondary crushers in a closed plant Excavate and transfer the raw material into a plant. Material is reduced in a jaw crusher. Material is screened either to the end-product pile or to a crusher to further reduction. Material is further reduced in a cone crusher. The end-product of your plant.

Improve safety and maintenance with our gyratory tooling

After your maintenance personnel use the crusher lock nut and bolt tightening tool once, they will never want to do without it. Our tool system makes maintenance work safer and faster. Reliable and consistent tightening with impact hammer; Simplified removal for difficult applications; Replaces antiquated manual slugging with a safer method