Flotationreagents For Iron Ore Beneficiation

Handbook of Flotation Reagents: Chemistry, Theory and

Initially the beneficiation of celestite ore was mainly physical concentration involving gravity, magnetic separation, and in some cases heavy liquid separation. Nowadays flotation becomes the most efficient way for the production of high-grade celestite. Select Chapter

(PDF) Flotation of Iron Ores: A Review ResearchGate

2019年11月19日This stone also describes a large variety of reagents commonly used or in development in each flotation route, covering collectors, activators, depressants,

Iron Ore Processing, General SpringerLink

2022年10月20日The three types of flotation reagents are collectors, frothers, and modifiers. Magnetic separation is a simple, yet effective method of iron ore

(PDF) An overview of the beneficiation of iron ores via

2014年3月1日Flotation is the most effective solution, both technologically and economically, when upgrading iron concentrates. Research

Iron Ore Clariant Ltd.

Iron ore flotation reagents dewatering and filtering agents pelletizing aids and binders Clariant’s portfolio includes a comprehensive range of collectors and frothers for iron ore flotation to remove undesirable mineral impurities.

Froth Flotation of Iron Ores

2012年1月2日The history of iron ore flotation started with direct flotation of iron oxides using anionic collectors such as petroleum sulphonate, fatty acids and hydroxamates. In

Mineral and metal processing Arkema Global

Mineral processing and beneficiation: CustoFloat® and CustAmine® collectors for titanium, iron and pegmatite flotation to meet maximum allowed concentrations; Rheosperse™

Mineral Processing Reagents Vintech Ltd

Reagents for the following applications are available: Iron Ore Beneficiation: alumina and silica collector used in the beneficiation (reverse floatation process) of low grade iron ore. Barite Beneficiation:

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日A 6-cell No. 24 Free-Flow Flotation Machine will effectively treat 35 to 40 LTPH of iron concentrates down to the desired limit, usually 4 to 6% SiO2. Loss of iron in the froth is low. The rough froth may be

Role of Surfactants in Mineral Processing: An Overview

2019年6月24日Microbial flotation reagents are currently gaining attention as natural bacteria can be used in place of toxic chemicals from the environmental point of view, Beneficiation of alumina-rich Indian iron

Froth Flotation of Iron Ores

2012年1月2日The history of iron ore flotation started with direct flotation of iron oxides using anionic collectors such as petroleum sulphonate, fatty acids and hydroxamates. In 1950s, the direct flotation route was integrated in plants, including Humboldt Mine (USA, 1954), Republic Mines, (USA, 1956), and Anshan IronSteel Corporation, (China, 1958).

Mineral and metal processing Arkema Global

Mineral processing and beneficiation: CustoFloat® and CustAmine® collectors for titanium, iron and pegmatite flotation to meet maximum allowed concentrations; Rheosperse™ dispersing agents for a wide range of Kaolin grades; Process water management: CustoFloc™ flocculants for tailings flocculation of fine clays. Feldspar

Analysis of reverse cationic iron ore fines flotation using RSM-D

2018年12月1日Kaolinite is a common gangue mineral in iron ore and sodium silicate has been used widely as a dispersant of silicate gangue minerals including kaolinite in various iron-ore flotation methods over a Expand 31 PDF Alkyl aminated nanocelluloses in selective flotation of aluminium oxide and quartz O. Laitinen, R. Hartmann, +4 authors

(PDF) Reagents in iron ores flotation ResearchGate

2005年2月1日The role of reagents utilised in iron ores flotation is reviewed. Desliming and flotation stages should be performed at pH levels as low as possible to reduce the expenses with caustic soda....

Differences in Etheramines Froth Properties and the Effects on Iron Ore

2022年2月17日Froth flotation is widely used for upgrading of ores and other materials. Efficiency of flotation depends on many parameters, including type, chemical structure and dose of flotation reagents. Expand 13 PDF Facile determination of foamability index of non-ionic and cationic frothers and its effect on flotation of quartz

Hematite Processing by Flotation Mineral Processing

2016年4月19日Direct shipping of high grade iron ore, because of depletion or partial depletion of reserves, or high costs of operation has forced operators to use some means of beneficiation to produce an

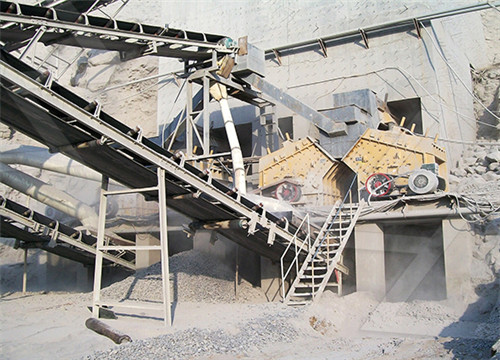

Iron-process flotation reagents for iron ore beneficiation

2012年9月30日National Metallurgical Laboratory Technology Offer:gyratorycrusher/quarry/process-line/iron-ore-processing-plant.htmlBeneficiation of iron o...

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

Online Library Fine Coal Beneficiation And Recovery Energy

Beneficiation Studies of Ore from Lutzputz Iron Ore Beneficiation Recovery of Uranium Flotation Reagents: Chemistry, Theory and Practice is a condensed form of the fundamental knowledge of chemical reagents commonly used in flotation and is addressed to the researchers and

Minerals Free Full-Text The Distribution Regularity and Flotation

2023年3月10日The characteristics of Baiyun Obo niobium-bearing minerals are complex physicochemical properties that make the beneficiation of niobium minerals extremely difficult. In this , X-ray diffraction, X-ray fluorescence and mineral liberation analyzer (MLA) systems were used to study the niobium occurrence state and distribution of

Feldspar BeneficiationFlotation Process

2016年4月14日Beneficiation by Flotation of feldspar is well established. It is a simple matter by flotation to remove the contaminating impurities and keep the alumina (Al2O3) content at 19% even on low grade feldspar

Iron Ore Processing, General SpringerLink

2022年10月20日The three types of flotation reagents are collectors, frothers, and modifiers. Magnetic separation is a simple, yet effective method of iron ore beneficiation that exploit the difference in magnetic properties between the ore minerals in which magnetically susceptible materials are separated from a mixture using a magnetic force.

Handbook of Flotation Reagents: Chemistry, Theory and Practice

Purchase Handbook of Flotation Reagents: Chemistry, Theory and Practice 1st Edition. Print BookE-Book. ISBN , . Flotation beneficiation of different phosphate ore types; 26.4. Beneficiation of high iron and mixed iron, titanium ores; 26.5. Plant practice in beneficiation of phosphate ores; Chapter 27

Investigation of Adsorption Mechanism of Reagents (Surfactants)

Understanding of the interactions between iron oxides and flotation reagents is important both for flotation and agglomeration of iron ore. Model systems comprising synthetic iron oxides and pure chemical reagents are commonly applied in experimental work in order to obtain high quality data and to ease the interpretation of the empirical data.

New perspectives in iron ore flotation: Use of collector reagents

2021年8月15日In conventional operations of iron ore beneficiation by flotation, the flotation feed is deslimed to remove the 10 µm fraction prior to flotation (Filippov et al 2014), thus the unselective flocculation effect of starch does not affect the flotation selectivity. Contrary to what occurred in this study, where the pure mineral samples used for

Iron Ore Processing, General SpringerLink

2022年10月20日Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills. Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions.

Literature review on the use of natural products in the flotation

2017年7月1日Cationic flotation reagents for mineral beneficiation; V.A. Glembotsky Iron ore flotation is now well established commercially around the globe, where large tonnages are treated to provide economically viable upgrading for a variety of oxide ore types. In this chapter, a brief history of the development of iron ore flotation is first given

Michigan Technological University Digital Commons

1.2.1 Iron Ore Beneficiation Process Overview Triangle of flotation reagents: collectors, frothers, and modifiers...6 Figure 1.6: Amylose structure. greater than 2.65 (Zhang et al., 2019). Iron ore flotation is commonly performed at basic pH conditions where silica and hematite have negative surface charges.

Five main classes of collectors used in iron ore flotation.

The low grade ores invariably liberate in finer sizes and the fines contain good amount of iron values in it. Flotation is the most established solution, both technologically and economically...

Mineral and metal processing Arkema Global

Mineral processing and beneficiation: CustoFloat® and CustAmine® collectors for titanium, iron and pegmatite flotation to meet maximum allowed concentrations; Rheosperse™ dispersing agents for a wide range of Kaolin grades; Process water management: CustoFloc™ flocculants for tailings flocculation of fine clays. Feldspar

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5.

Technical Resource Document: Extraction and

and Beneficiation of Metallic Ores, Phosphate Rock, Asbestos, Overburden from Uranium Mining and Oil Shale (U.S. EPA, 1985). In July 1986, EPA made a regulatory determination that regulation of extraction and beneficiation wastes under Subtitle C was not appropriate (51 FR 24496; July 3, 1986). EPA concluded

Iron-process flotation reagents for iron ore beneficiation

2012年9月30日National Metallurgical Laboratory Technology Offer:gyratorycrusher/quarry/process-line/iron-ore-processing-plant.htmlBeneficiation of iron o...

Online Library Fine Coal Beneficiation And Recovery Energy

Beneficiation Studies of Ore from Lutzputz Iron Ore Beneficiation Recovery of Uranium Flotation Reagents: Chemistry, Theory and Practice is a condensed form of the fundamental knowledge of chemical reagents commonly used in flotation and is addressed to the researchers and

BENEFICIATION OF IRON ORE National Institute of

(1992) Beneficiation of iron ore slimes using hydrocyclone. Mineral and Metallurgical Processing, 9 (2): 101–103. 5. Brief Final report on characterization of Banded Hematite Jasper. 6. Minutes of 43rd meeting of the central geological programming board on 29.09.2008, Ministry of Mines, New Delhi. 7.

Minerals Free Full-Text The Distribution Regularity and Flotation

2023年3月10日The characteristics of Baiyun Obo niobium-bearing minerals are complex physicochemical properties that make the beneficiation of niobium minerals extremely difficult. In this , X-ray diffraction, X-ray fluorescence and mineral liberation analyzer (MLA) systems were used to study the niobium occurrence state and distribution of

Mineral Processing Reagents Vintech Ltd

Vintech Ltd supplies a variety of reagents for coal preparation and beneficiation of mineral ores. We work with our customers to develop custom-made flotation reagents for specific applications to ensure optimal mineral recovery. Our key products are environmentally friendly replacements for chemical and petroleum based flotation reagents.