Iron Ore Process Plant Block Diagram

Iron processing Definition, History, Steps, Uses,Facts

Iron is allotropic—that is, it exists in different forms. Its crystal structure is either body-centred cubic (bcc) or face-centred cubic (fcc), depending on the temperature. In both crystallographic modifications, the basic

The six main steps of iron ore processing Multotec

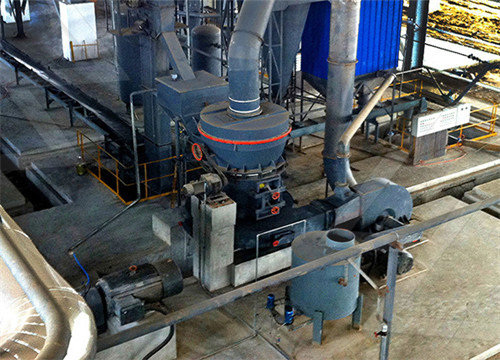

Screening. We recommend that you begin by screening the iron ore to separate fine

Welcome to the IIMA International Iron Metallics Association

Welcome to the IIMA International Iron Metallics Association

Direct reduced iron process tec-science

2018年6月21日The reduction of iron oxides takes place according to the following chemical equations: (1) F e 2 O 3 + 3 C O → 2 F e + 3 C O 2

Mineral Processing Flowsheets

2016年3月8日The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

12.5 Iron And Steel Production US EPA

diagram of the iron and steel industry in Figure 12.5-1. Coke production is discussed in detail in Section 12.2 of this publication, and more information on the handling and

Block Flow Diagram processdesign Northwestern

2015年3月1日A block flow diagram (BFD) is a drawing of a chemical processes used to simplify and understand the basic structure of a system. A BFD is the simplest form of the flow diagrams used in industry. Blocks

Beneficiation Plants and Pelletizing Plants for Utilizing

1.3 Structure of iron ore supply The suppliers of iron ore have undergone strategic restructuring since 2000. Three majors, namely, Vale (Brazil), Rio Tinto, and BHP Billiton

Blast furnace Definition, Temperature, Diagrams,Facts

2023年1月31日The furnace charge, or burden, of iron-bearing materials (e.g., iron ore pellets and sinter), coke, and flux (e.g., limestone) descends through the shaft, where it is preheated and reacts with ascending reducing gases to produce liquid iron and slag that accumulate in the hearth.

Welcome to the IIMA International Iron Metallics Association

Welcome to the IIMA International Iron Metallics Association

Direct reduced iron process tec-science

2018年6月21日The process gases carbon monoxide ( C O) and hydrogen ( H 2) are blown into the furnace at temperatures of approx. 1000 °C and flow through the iron ores. The reduction of iron oxides takes place according to the following chemical equations: (1) F e 2 O 3 + 3 C O → 2 F e + 3 C O 2 (2) F e 2 O 3 + 3 H 2 → 2 F e + 3 H 2 O

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

Block Flow Diagram processdesign Northwestern University

2015年3月1日A block flow diagram (BFD) is a drawing of a chemical processes used to simplify and understand the basic structure of a system. A BFD is the simplest form of the flow diagrams used in industry. Blocks in a BFD can represent anything from a single piece of equipment to an entire plant.

11.23 Taconite Ore Processing US EPA

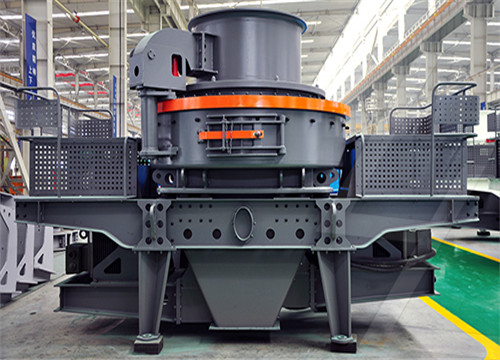

11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

Block Flow Diagram an overview ScienceDirect Topics

The BtL process. A block-flow diagram of a standard BtL process is shown in Fig. 6.11. The biomass is first dried and pretreated by pyrolysis or torrefaction. Gasification takes place at an elevated pressure of 10–40 bar, which is advantageous for equipment size (costs), thermodynamics, and kinetics [14].

How Steel is Made Using the Basic Oxygen Steelmaking

Iron-Ore Iron-ore are rocks and minerals that contain the metal iron (Iron Ore). Iron-ore is harvested in large-scales through various mining techniques (STEEL: From Start to Finish). The iron-ore is ground to a powder and then the ore is separated with strong magnets (STEEL: From Start to Finish). The ore is then heated and formed into marble

Flow diagram of iron ore sintering process [13] ResearchGate

A flow diagram of ore sintering is shown in Figure 3. The mix is sintered on a continuous, traveling grate called a sinter strand, which consists of multiple trolleys whose number is specific for

Process flow diagram of the sponge iron plant. ResearchGate

As the name suggests direct reduced iron plant utilizes the method of solid-state reduction of Iron Ore to Iron. The reduction process is based on both exothermic and endothermic...

Pilbara Rio Tinto

Our process plant has an annual, average capacity of 43Mtpa of iron ore. Innovation in the Pilbara Our integrated iron ore network is supported by our Operations Centre in Perth, a state-of-the-art facility that enables all the autonomous trucks, trains and drills at our mines, ports and rail systems to be operated from a single location.

Block Flow Diagram Guide for Modeling Chemical Processes

Block Flow Diagram Guide for Modeling Chemical Processes A block flow diagram (BFD) is a drawing of chemical processes used to simplify and understand the basic structure of a system suggested by PetersTimmerhaus, in 2003. A BFD is the simplest form of the flow diagrams used in the industry.

Deep Learning Approach at the Edge to Detect Iron Ore Type

This issue causes tons of iron ore to travel for significant distances, destroying structures in front of them, causing material damage, and potentially reaching plant operators, causing injuries and even death. Figure 1 shows an avalanche event in an iron ore plant. The operational teams can visually recognize and classify which type of iron

Lithium Mining Processing Equipment Flow Chart Cases JXSC

What is Lithium. Lithium is an element valuable for the production of glass, aluminum products, and batteries. It is mined from ores of petalite (LiAl (Si2O 5) 2, lepidolite K (Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl (SiO 3) 2 and also subsurface brines. Australia and Chile are the world’s largest producers of lithium.

Welcome to the IIMA International Iron Metallics Association

Welcome to the IIMA International Iron Metallics Association

Pilbara Rio Tinto

Our process plant has an annual, average capacity of 43Mtpa of iron ore. Innovation in the Pilbara Our integrated iron ore network is supported by our Operations Centre in Perth, a state-of-the-art facility that enables all

Direct reduced iron process tec-science

2018年6月21日The process gases carbon monoxide ( C O) and hydrogen ( H 2) are blown into the furnace at temperatures of approx. 1000 °C and flow through the iron ores. The reduction of iron oxides takes place

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Simplified process flowsheet of Itakpe iron ore

Download scientific diagram Simplified process flowsheet of Itakpe iron ore processing plant Source: Ajaka (2009) Production methods and procedures for the production of 1.5mt capacity of Iron

Electric Arc Furnace Process an overview ScienceDirect

The Basic Oxygen Furnace process uses 25 to 35 percent old steel to make new steel. The iron-iron carbide phase diagram is a good basis for understanding the effect of temperature and components on the properties of steel. For typical high iron ore grades (60–66% iron), a BF normally produces approximately 0.25–0.30 tonne (0.28–0.33

Block Flow Diagram processdesign Northwestern

2015年3月1日A block flow diagram (BFD) is a drawing of a chemical processes used to simplify and understand the basic structure of a system. A BFD is the simplest form of the flow diagrams used in industry. Blocks

11.23 Taconite Ore Processing US EPA

11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

How Steel is Made Using the Basic Oxygen Steelmaking

Iron-Ore Iron-ore are rocks and minerals that contain the metal iron (Iron Ore). Iron-ore is harvested in large-scales through various mining techniques (STEEL: From Start to Finish). The iron-ore is ground to a powder and then the ore is separated with strong magnets (STEEL: From Start to Finish). The ore is then heated and formed into marble

Flow diagram of iron ore sintering process [13]

Iron ore sintering is the main process of fines agglomeration for ironmaking with relevant particulate matter and trace element emissions of integrated steel plants. Due to the high...

Block Flow Diagram an overview ScienceDirect Topics

The BtL process. A block-flow diagram of a standard BtL process is shown in Fig. 6.11. The biomass is first dried and pretreated by pyrolysis or torrefaction. Gasification takes place at an elevated pressure of 10–40 bar, which is advantageous for equipment size (costs), thermodynamics, and kinetics [14].

Sinter plant Wikipedia

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace.The final product, a sinter, is a small, irregular nodule of iron

Lithium Mining Processing Equipment Flow Chart Cases JXSC

What is Lithium. Lithium is an element valuable for the production of glass, aluminum products, and batteries. It is mined from ores of petalite (LiAl (Si2O 5) 2, lepidolite K (Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl (SiO 3) 2 and also subsurface brines. Australia and Chile are the world’s largest producers of lithium.

Deep Learning Approach at the Edge to Detect Iron Ore Type

This issue causes tons of iron ore to travel for significant distances, destroying structures in front of them, causing material damage, and potentially reaching plant operators, causing injuries and even death. Figure 1 shows an avalanche event in an iron ore plant. The operational teams can visually recognize and classify which type of iron

- 一车石头多少吨

- 云南临时采矿证

- 石料场

- Crushing Of Gold In Mining Process Ghana

- 制砂用鹅卵石价格多少钱一吨

- 衍纸与超轻粘土的组合作品图片

- Gold Mining In Bogoso

- Paint Manufacturing Process Flow Chart

- Guidelines For Stone Crushing Plant Rajasthan

- 贵州矿山分布

- Used Complete Mining Mill For In Czech Republic And Germany

- 时产200吨建筑垃圾破碎站

- 德国矿山设备公司

- 高性能液压产品

- 向工商部门申请办理采石厂营业执照需哪些资料