Concrete Mining Mill Application In Mineral Industry

MiningMinerals Industry Handled Vortex

Because application parameters in mining and minerals greatly vary, proper modifications to standard valves is the key to getting the most out of your components. Durability –Our

进一步探索

Wayne Revell Magnum Systems, Kansas City, KansasList of Rotary Valve Manufacturers Rotary Valves根据热度为您推荐•反馈

Mining and mineral processing industries ABB

Mining companies are adapting their strategy to address energy costs and regulations requiring a quota of renewable sources from energy generators. Energy use in mining

Mineral Industry Surveys U.S. Geological Survey

By National Minerals Information Center. Mineral Industry Surveys (MIS) are periodic on-line statistical and economic publications designed to provide timely statistical data on

Are You Mining Minerals for Cement, or for Concrete?

2017年8月1日The concrete is the final product used in buildings, roads, infrastructure, etc. You can think of cement as the “glue” that holds the sand and gravel and re-bar

California MiningMinerals Bureau of Land

BLM collaborates with members of the public, representatives of private industry, local and state government agencies, and Native American tribes to carry out the mineral

FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY

2003年1月1日Germany, is the only high-speed stirred mill in operation in the minerals industry. The The advantages of the mill is relatively high throughput (above 10 tph) at

Deep Learning in Mining and Mineral Processing

2020年1月1日The purpose of this stone is to provide a review of emerging applications of deep learning in mining and metallurgical operations. Deep Learning in Mining and

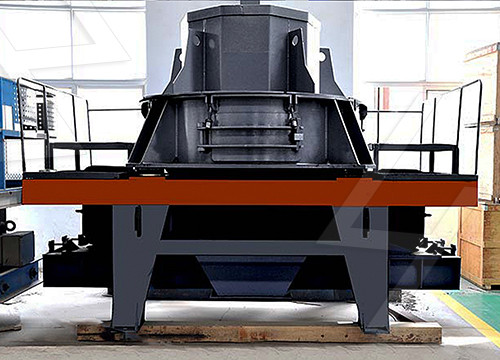

Grinding Mill Product Applications in Durability of Concrete

2016年2月17日One method of improving concrete performance is to add mineral admixtures, such as slag powder. Added with slag powder, concrete will get better

Pumps and Mixers for Mineral Processing Hayward Gordon

Our application experts understand the technical challenges of the mining industry. We work closely with you to assess your mining operation, determine the best process

Review on advances in mineral processing technologies suitable

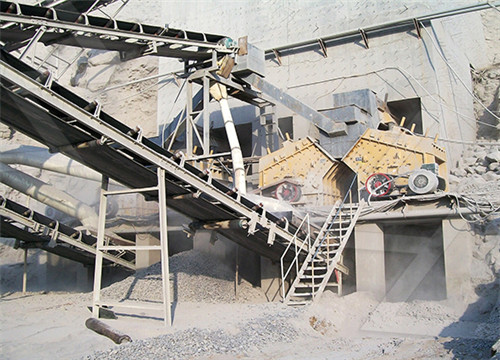

2022年4月1日Mineral processing operations generally follow a set of specific steps to separate ores into products rich in valuable minerals (concentrate) and waste streams. The breakdown of the mineral processing steps within the mining chain is illustrated in Fig. 3. Run of mine ore undergoes an initial process of crushing, milling and classification to

Materials Flow U.S. Geological Survey

Evaluating the Mineral Commodity Supply Risk of the U.S. Manufacturing Sector Risk tool identified 23 mineral commodities whose supply poses the greatest risk, including those used in consumer electronics, renewable energy, aerospace, and defense applications. Flow Studies for Recycling Metal Commodities in the United States

Mining and mineral processing industries ABB

Mining companies are adapting their strategy to address energy costs and regulations requiring a quota of renewable sources from energy generators. Energy use in mining and mineral processing is strongly dependent on the ore quality and ore composition. The energy requirements for open-pit mining are different to underground mining.

Minerals Free Full-Text A Systematic Review on the Application

2021年7月28日ML, a revolutionary new method of handling vast amounts of data, has been developed in the past few years to the point where it can be applied to mineral processing applications. The combination of more sophisticated instrumentation in conjunction with ML has the potential to revolutionize mineral processing standard

Optimizing processes in Southeast Asia’s mining industry

2023年3月1日Around the world, tech-enabled process optimization has been at the core of improvements in efficiency for all major front-runners in the mining industry. 11 Traditionally, companies in the mining industry have relied heavily on individual experience combined with first principles to drive productivity.

MiningMineral Processing Equipment FEECO International Inc.

Mining and Mineral Processing Equipment FEECO Mining Capabilities Our equipment and solutions are used around the world in a variety of mining and mineral processing operations. We’ve worked with everyone from process start-ups and entrepreneurs, to Fortune 100 companies. Equipment

Minerals Free Full-Text Blast Furnace Slag, Post-Industrial Waste

2022年4月14日Blast Furnace Slag is used in the construction industry as a mineral amendment or aggregate. Their use in Earth Construction, due to their post-industrial origin, may be associated with increased levels of potentially toxic elements (PTE) in the soil.

Mining Applications Regular Existing Mining and Minerals

Mining Applications Regular Existing Mining and Minerals Mining Applications Regular Existing Pending and Approved Mine Applications Bernalillo County BE001RE Tijeras Mine, Modification 22-1 Reference Area and Reclamation Success Criteria BE001RE Tijeras Mine, Modification 21-2 Quarry Design Limit Expansion

TA001RE Questa Mine and Mill Mod 19-1 Mining and Minerals

TA001RE Questa Mine Chevron Mining, Inc., Questa, New Mexico Molybdenum, Taos County. May-2020 Updated FA. Apr-2020 MMD Letter, Technically Complete Mod 19-1. Mar-2020 CMI Letter, FA Instruments for Mod 19-1. Jan-2020 MMD Letter, FA Instruments for Mod 19-1. Sep-2019 Letter, Administratively Complete. Aug-2019 FA Calculation,

FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY

2003年1月1日Germany, is the only high-speed stirred mill in operation in the minerals industry. The The advantages of the mill is relatively high throughput (above 10 tph) at very low product size (80%

Grade Control Bruker

Grade control is the classification of reserves into ore, low grade, waste material or metallurgical types. X-Ray Fluorescence (XRF) is the most accepted analytic technology for grade control in mineral production and processing. Bruker’s wide range of XRF instrumentation can meet any need in production monitoring for mining in the goal of

A Systematic Review on the Application of Machine Learning in

2021年7月28日the mining and minerals industry have been addressed using ML techniques. The dataset containing geochemical data was used for extracting features related to mineralization

Mineral Industry Surveys U.S. Geological Survey

Mineral Industry Surveys (MIS) are periodic on-line statistical and economic publications designed to provide timely statistical data on production, distribution, stocks, and consumption of significant mineral commodities. These publications are issued monthly, quarterly, or annually. Industry Data U.S. Production of Selected Mineral Commodities

Mining and Mineral Market Filtration Donaldson Company

for the mineral industry Most popular products p. 4 p. 6 p. 5 7 p. 8 p. 1 3 DONALDSON®: YOUR SINGLE FILTRATION SOURCE FOR MINING AND MINERALS Large flows of abrasive dust are typical in all mining and mineral processing applications. Without effective dust control, equipment and process are put at risk. With an extensive portfolio

Review on advances in mineral processing technologies suitable

2022年4月1日Mineral processing wastes are generated during the concentration of economical metals and minerals, and include tailings, sludges, and mill water (Lottermoser, 2010). Tailings, which are a mixture of non-economical crushed rock and processing fluids generated from a mill, washery or concentrator during mineral processing, are the main

Materials Flow U.S. Geological Survey

Mines and Mineral Processing Facilities in the Vicinity of the March 11, 2011, Earthquake in Northern Honshu, Japan Open-File Report 2011–1069; Mining Review--Annual Review 2017 Mining Engineering, v.70, no.5, May, p.51-60; Mining Review--Annual Review 2018 Mining Engineering, v.71, no.5, May, p.51-60

Mining and mineral processing industries ABB

Mining companies are adapting their strategy to address energy costs and regulations requiring a quota of renewable sources from energy generators. Energy use in mining and mineral processing is strongly dependent on the ore quality and ore composition. The energy requirements for open-pit mining are different to underground mining.

Optimizing processes in Southeast Asia’s mining industry

2023年3月1日Southeast Asia’s downstream-processing industry has recently seen rapid growth and expansion. Much of this industry is concentrated in Indonesia, with a smaller but significant presence in other Southeast Asian countries. Our research shows that since 2021, commodity prices for base metals such as nickel and copper have increased by 80

Eriez MiningMinerals Processing Industry

Equipment for the MiningMinerals Processing Industries Eriez is your go-to resource for the latest and most advanced equipment and solutions utilized in minerals processing. We are the leaders in a wide variety of mining applications, including Industrial Minerals, Iron Ore, Coal Processing and Hard Rock Mining.

MiningMineral Processing Equipment FEECO International Inc.

Critical Minerals R&D, Mineral Testing and Process Development. Industry: MiningMinerals. Industry: MiningMinerals. Resource of the Week: Mining Production Equipment Brochure. Rotary Kiln Gains Traction as E-Waste Crisis Looms, Metal Recovery from E-Waste. Metal Processing Infographic. Resource of the Week: Metals and

FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY

2003年1月1日Germany, is the only high-speed stirred mill in operation in the minerals industry. The The advantages of the mill is relatively high throughput (above 10 tph) at very low product size (80%

TA001RE Questa Mine and Mill Mod 19-1 Mining and Minerals

TA001RE Questa Mine Chevron Mining, Inc., Questa, New Mexico Molybdenum, Taos County. May-2020 Updated FA. Apr-2020 MMD Letter, Technically Complete Mod 19-1. Mar-2020 CMI Letter, FA Instruments for Mod 19-1. Jan-2020 MMD Letter, FA Instruments for Mod 19-1. Sep-2019 Letter, Administratively Complete. Aug-2019 FA Calculation,

Mining Applications Regular Existing Mining and Minerals

GR002RE Continental Mine and Mill, 2022 Exploration Activity. SF002RE LAC Minerals Cunningham Hill, Revision 20-1. Sierra County. SI006RE St. Cloud Mining Company, Closeout Plan Updated Application. SI006RE St. Cloud Mining Company, Closeout Plan Updated Cost Estimate. SI006RE St. Cloud Mining Company, Modification 20-1 South

Grade Control Bruker

Grade control is the classification of reserves into ore, low grade, waste material or metallurgical types. X-Ray Fluorescence (XRF) is the most accepted analytic technology for grade control in mineral production and processing. Bruker’s wide range of XRF instrumentation can meet any need in production monitoring for mining in the goal of

Pumps and Mixers for Mineral Processing Hayward Gordon

The Hayward Gordon Group designs, develops, and delivers durable, reliable pumps and mixers ideal for the mining industry. Our pumps effortlessly move thick, heavy slurries, and withstand the corrosive and toxic chemicals used in mining and mineral processing. On our peristaltic pumps, the hose is the only component that directly contacts the

Technologies in Exploration, Mining, and Processing

The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land use. New technologies can benefit the mining industry and consumers in all stages of this life cycle. This report does not include downstream processing, such as smelting of mineral concentrates or refining of metals.

Minerals Special Issue : Advances in Computational Intelligence

2021年9月17日It is not a new field for mining industry applications. Until now, however, applications were mostly academic where members of academia applied various computational intelligence (CI) techniques to whatever datasets the industry was comfortable sharing with academia. Our envisioned application is rock and mineral

Mineral Processing an overview ScienceDirect Topics

Mining and mineral-processing industries producing lithium minerals, metals, and salts contribute to the lithium burden in the environment. The processing of lithium-containing minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as