No Of Crushers Required In Cement Plant

United States Environmental Protection Agency

1. Concrete Batch Plant Source Category Definition A concrete batch plant is an operation that combines various ingredients to form concrete. Some of these inputs include sand,

Cement Crusher Crusher In Cement Plant AGICO Cement

As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of

How many employees require a Cement Plant?

Counting CriteriaGeographyDesign and Level of ModernizationPeople EfficiencyConclusions

The companies have different criteria for the classification of employee and subcontractors, anOutsourcing Operation areas.- Several companies around 1990 started outsourcing the Quarry Operation, under different kind of contracts; paying for ton produced or for the number of hand labor. The Cement Packing Area (Dispatch)sometimes is operated almost completely for extern在linkedin上查看更多信息评论数: 116

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

2019年11月21日For meeting different requirements, we also provide single cement plant equipment, including cement crusher, cement ball mill, vertical cement mill, cement

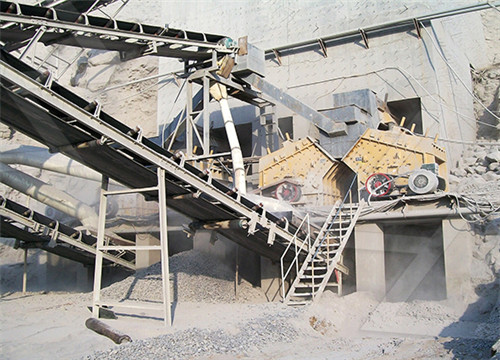

Cement Crusher For Sale Jaw Crusher, Cone Crusher AGICO

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line.Before sending it into the

Energy consumption assessment in a cement production

2015年6月1日Brunke and Blesl [4] evaluated the energy conservation and CO 2 abatement potential of 21 identified measures in a German cement production plant and

Cement Plant Crushers Manufacturers Jaw Crushers

Jaw crushers. 4. Roller crushers. Hammer Crushers: Raw materials from quarry are now routed in Cement Plant laboratory where, they are analyzed and proper proportioning of

Concrete Plants SCDHEC

Concrete batch plants, concrete block production facilities, and pug mills may be eligible for coverage under the general construction permit and the general state or general

United States Environmental Protection Agency General

1. Concrete Batch Plant Source Category Definition A concrete batch plant is an operation that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate (rocks, gravel, etc.), fly ash, potash, and cement. There are two types of concrete batch plants: ready mix plants and central mix plants.

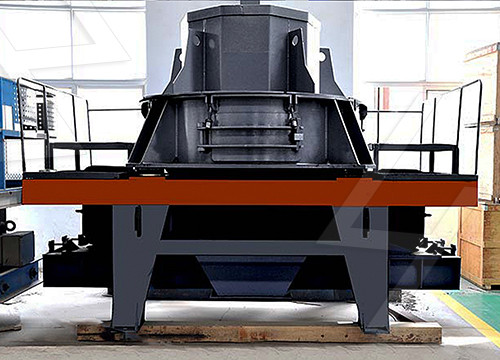

Cement Crusher Crusher In Cement Plant AGICO Cement

As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw material crushing: cone crusher, impact crusher, hammer crusher, jaw crusher, and four-roll crusher. How To Select Cement

Dirt, Sand, and Rock Quarries and Aggregate Processing Plants

Rock and Concrete Crushers — If your facility includes a rock or concrete crusher, you must register it under one of these standard permits: Temporary Rock and Concrete Crushers Permanent Rock and Concrete Crushers Other New Source Review Authorizations Back to top Water San Jacinto Sand Mines/30 TAC 311, Subchapter J

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

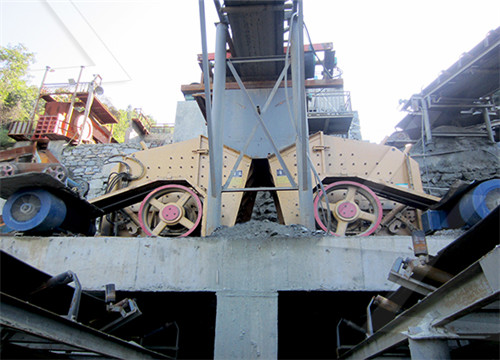

Cement Plant Crushers Manufacturers Jaw Crushers Roller Crushers

Jaw crushers. 4. Roller crushers. Hammer Crushers: Raw materials from quarry are now routed in Cement Plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay. Impact Crushers: Impact crusher is

Concrete Plants SCDHEC

Concrete batch plants, concrete block production facilities, and pug mills may be eligible for coverage under the general construction permit and the general state or general conditional major operating permits if the only sources of emissions are as follows: temporary/portable crushing and screening equipment for nonmetallic minerals

AIR POLUTION AND AIR POLLUTION CONTROL IN CEMENT

2017年12月20日The specific emissions limits for nitrogen oxides are 750 mg/Nm3, or 260 nano grams per joule (ng/J), or 365 parts per million parts (ppm) for a coal-fired power plant, and up to 1,500 mg/Nm3 for plants using coal with volatile matter less than 10%; 460 mg/Nm3 (or 130 ng/J, or 225 ppm) for an oil-fired power plant; and 320 mg/ Nm3 (or 86

Energy consumption assessment in a cement production plant

2015年6月1日Brunke and Blesl [4] evaluated the energy conservation and CO 2 abatement potential of 21 identified measures in a German cement production plant and concluded that the economical conservation and abatement potential for the year 2013 of 4% for fuel, 0.7% for electricity and 3.4% fuel and process-related CO 2 emissions

Energy and Economic Comparison of Different Fuels in Cement

2021年5月3日Energy cost contributes to about 40–50% of cement production cost in Nigeria depending on the production process and type of cement with 1 tonne of cement requiring 60–130 kg of fuel or its equivalent and about 105 kWh of electricity [ 3 ]. Fossil fuels like coal, pet coke, fuel oil, and gas are the primary fuels used in the cement kilns.

Stone Dust in Concrete: Effect on Compressive Strength

natural sand by crusher dust increased the compressive strength of concrete by 5-22% and it was also found that amongst all the mixes, the highest compressive strength was obtained for 40% replacement of sand by crusher dust (Quadri et al., 2013). The required slump could not be achieved by

Special Equipments for CementMining Industry Asian Century

Typically, cement plants/ power plants locations are based upon the availability of good quality raw materials (limestonecoal) in the vicinity. The quarrying operations are done by the cement producer/power producer using the open cast mining process. The quarried raw material is then transported to the cement plant/power plant.

Energy consumption assessment in a cement production plant

2015年6月1日The type of cement production process in the studied cement plant is typical dry process Portland cement and consists of three major steps. In the first step, certain portion of clay and limestone are blended together and then the mixture is crushed to form a powder. The raw material mills in the studied plant are of the roller mills type.

Primary Crusher an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Cement Plant Crushers Manufacturers Jaw Crushers Roller Crushers

Cement Plant Crushers Grinding Machine Manufacturer Cement Plant requires raw materials including calcium, silicon, iron and aluminum majorly. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sandclay fulfill the need of silicon, iron and aluminum.

Concrete Plants SCDHEC

Concrete batch plants, concrete block production facilities, and pug mills may be eligible for coverage under the general construction permit and the general state or general conditional major operating permits if the only sources of emissions are as follows: temporary/portable crushing and screening equipment for nonmetallic minerals

Energy and Economic Comparison of Different Fuels in Cement

2021年5月3日Energy cost contributes to about 40–50% of cement production cost in Nigeria depending on the production process and type of cement with 1 tonne of cement requiring 60–130 kg of fuel or its equivalent and about 105 kWh of electricity [ 3 ]. Fossil fuels like coal, pet coke, fuel oil, and gas are the primary fuels used in the cement kilns.

Stone Dust in Concrete: Effect on Compressive Strength

natural sand by crusher dust increased the compressive strength of concrete by 5-22% and it was also found that amongst all the mixes, the highest compressive strength was obtained for 40% replacement of sand by crusher dust (Quadri et al., 2013). The required slump could not be achieved by

AIR POLUTION AND AIR POLLUTION CONTROL IN CEMENT

2017年12月20日The specific emissions limits for nitrogen oxides are 750 mg/Nm3, or 260 nano grams per joule (ng/J), or 365 parts per million parts (ppm) for a coal-fired power plant, and up to 1,500 mg/Nm3 for plants using coal with volatile matter less than 10%; 460 mg/Nm3 (or 130 ng/J, or 225 ppm) for an oil-fired power plant; and 320 mg/ Nm3 (or 86

Standard Permit for Rock and Concrete Crushers: Learning More

2022年7月5日A typical crusher authorized by this Standard Permit might have these components: a primary crusher, to break large rocks into chunks a secondary crusher, to break those chunks down into smaller pieces two screening units, to separate the crushed rock by size conveyors to carry materials from stockpiles to the crushers

Special Equipments for CementMining Industry Asian Century

Typically, cement plants/ power plants locations are based upon the availability of good quality raw materials (limestonecoal) in the vicinity. The quarrying operations are done by the cement producer/power producer using the open cast mining process. The quarried raw material is then transported to the cement plant/power plant.

no of crushers required in cement plant

The use of concrete pumps, mixer trucks, crushers, cement silos, and the type of concrete batching plants also affect the productivity. For example, if you want faster mobility, installation, frequent relocation, and build temporary construction sites, mobile concrete batching plants are considered to be the best option.