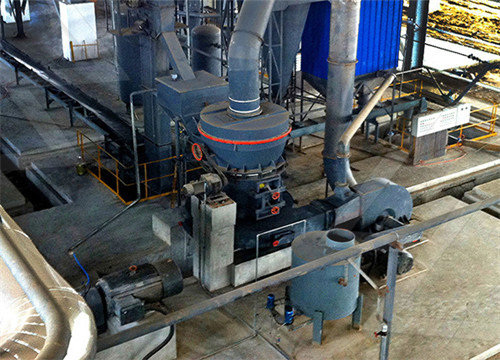

Allmineral Iron Ore Crushing Plant

allmineral Mining Technology

allmineral has strengthened its management team with the addition of Dipl.- Ing. Andreas Hees. Andreas, who was born in Tübingen, Germany, is a proven specialist in raw materials processing, particularly iron ore. With

Pilot Plant allmineral

Feed materials (samples) for crushing tests must be provided by the customer. For the normal test program, two (2) to four (4) 55-gallon

News allmineral Aufbereitungstechnik GmbHCo. KG

2016年3月22日Originally produced in Russia and featuring conventional jiggers, the existing processing plant was no longer capable of simultaneously processing the entire

allmineral's processing efficiency to boost quality of Kazakh iron ore

2018年3月22日With the new, revamped plant, we expect annual capacity to increase to 1.7 million tons from the current 1.5 million and for the Fe content to increase from 40.6%

allmineral booms in iron ore: contracts still rolling in from Australia

2011年6月24日Posted by Matrix on 24th June 2011. allmineral has been awarded three independent contracts to supply its mineral processing products and equipment to the

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

IRON ORE CRUSHING PLANT, IRON ORE PROCESSING

2022年2月20日iron ore crushing and processing for steel preparation, iron ore processing, iron ore for steel plant, iron ore for steel making, steel prepared by iron ore....

allmineral ore processing with alljig® allmineral

allmineral ore processing with alljig® allmineral Aufbereitungstechnik GmbHCo. KG Our fascinating reference from Iron Baron in Australia demonstrates how an alljig® jigger can achieve efficient iron ore production. Take a look now! Phone: + 49 (0) 211 / 522 88 0 E-Mail: head@allmineral Spare PartsService Inquiries

allmineral Mining Technology

allmineral plants are located in Europe, India, Australia, North and South America, as well as South Africa. Today there are more than 750 allmineral plants in operation around the world, reliably and efficiently applying both

News allmineral Aufbereitungstechnik GmbHCo. KG

2016年3月22日Originally produced in Russia and featuring conventional jiggers, the existing processing plant was no longer capable of simultaneously processing the entire grain spectrum of the iron ore being produced. The plant had to be adjusted to handle the separation, enrichment and cleaning of the fine (< 10 mm) and coarse (10-60 mm)

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日700tph Iron Ore Crushing Plant Capacity: 700t/h Material: iron ore Equipment: Jaw crusher, impact crusher, cone crusher, circular vibrating screen, belt conveyor Get Free Flow Design WhatsApp Instant Reply project background Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here.

allmineral booms in iron ore: contracts still rolling in from

2011年6月24日Posted by Matrix on 24th June 2011. allmineral has been awarded three independent contracts to supply its mineral processing products and equipment to the Rio Tinto Low Grade Iron Ore Pilot Plant. The pilot plant, which will be located at the Brockman 4 mine site in Western Australia,60km north west of Tom Price, will play a strategic part in

Iron Ore Beneficiation Mineral Processing

Rock needs to be crushed to 5mm for releasing inside the iron Processing capacity: 500tph Require for dry process 1-Dump truck feeds raw ore to the hopper, then to the vibrating feeder. 2-Vibrating feeder evenly feeds the jaw crusher. jaw crusher crush big rock to a medium size less than 200mm

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

sbmchina/sbm iron ore upgrading machine for river sand.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

MRC runs for longer at Tormin

1 AddThis Utility Frame. Australasia Edition. Au 1867.27 $/oz. Pt 959.20 $/oz. Follow @MiningWeeklyAus. Home / Australasia Home ← Back.

Iron ore processing plant, Iron ore processing plant direct from

Iron ore processing plant from Jiangxi Walker Machinery Co., Ltd.. Search High Quality Iron ore processing plant Manufacturing and Exporting supplier on Alibaba. iron ore mobile crusher plant pallets ore crushing magnetic separation processing machine. $4,500.00 $12,000.00 / set. 1 set (Min. Order) Artificial Rock Production Line

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Iron-Ore Crushing Ball Mill Shalimar Engineering

Iron-oreother minerals Beneficiation Plant; Ore Crushing Plant; Cement Plant; Fertilizer Plant; Pesticide Plant; Sand Processing Plant; Stone Crushing Plant Quartz Grinding Plant; Coal Crushing and Screening Plant; Quarry For Stone Crushing Plant; Coal Handling Plant; CopperOther Mineral Ore Beneficiation Plant; Asphalt Mixing Plant;

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.

DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore

The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in the software

allmineral ore processing with alljig® allmineral

allmineral ore processing with alljig® allmineral Aufbereitungstechnik GmbHCo. KG Our fascinating reference from Iron Baron in Australia demonstrates how an alljig® jigger can achieve efficient iron ore production. Take a look now! Phone: + 49 (0) 211 / 522 88 0 E-Mail: head@allmineral Spare PartsService Inquiries

News allmineral Aufbereitungstechnik GmbHCo. KG

2016年3月22日Originally produced in Russia and featuring conventional jiggers, the existing processing plant was no longer capable of simultaneously processing the entire grain spectrum of the iron ore being produced. The plant had to be adjusted to handle the separation, enrichment and cleaning of the fine (< 10 mm) and coarse (10-60 mm)

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces.

allmineral booms in iron ore: contracts still rolling in from

2011年6月24日The alljig separates high density iron ore from gangue material using the processes of stratification and separation. The jig is fitted with flexible design features that allow it to treat fines and lump material up to 32 mm as well as treating wide ranging particle size ratios of up to 1:8.

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

sbmchina/sbm iron ore upgrading machine for river sand.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Iron ore processing plant, Iron ore processing plant direct from

Iron ore processing plant from Jiangxi Walker Machinery Co., Ltd.. Search High Quality Iron ore processing plant Manufacturing and Exporting supplier on Alibaba. iron ore mobile crusher plant pallets ore crushing magnetic separation processing machine. $4,500.00 $12,000.00 / set. 1 set (Min. Order) Artificial Rock Production Line

MRC runs for longer at Tormin

1 AddThis Utility Frame. Australasia Edition. Au 1867.27 $/oz. Pt 959.20 $/oz. Follow @MiningWeeklyAus. Home / Australasia Home ← Back.

Iron-Ore Crushing Ball Mill Shalimar Engineering

Iron-oreother minerals Beneficiation Plant; Ore Crushing Plant; Cement Plant; Fertilizer Plant; Pesticide Plant; Sand Processing Plant; Stone Crushing Plant Quartz Grinding Plant; Coal Crushing and Screening Plant; Quarry For Stone Crushing Plant; Coal Handling Plant; CopperOther Mineral Ore Beneficiation Plant; Asphalt Mixing Plant;

allmineral boosts production output of Brazilian manganese ore

2017年9月12日The plant for the efficient processing of extracted manganese ore from highly oxidised, iron and silicate-rich sedimentary rock will increase the annual output at the mine from 30,000 to 50,000 tonnes.

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.

allmineral supplies coal processing plant to SEKAKO Mining

2017年11月22日allmineral, world-renowned specialist in the preparation and processing of gravel, sand, coal and ore, has been awarded the contract to supply a state-of-the-art coal processing plant to Indonesian company SEKAKO Mining for operation in the newly opened 350,000 hectare coal mining area in central Kalimantan, Borneo.

DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore

The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in the software

- 冶金矿渣磨粉机械工作原理

- Supplier Mining Rod Mill Equipment

- Skullcandy Skull Crusher Abel Tarjeta Hig

- Advanced Type Sand Lime Brick Making Machine Of European Standard

- 采石场会计管理

- Supply Cone Crusher For Crushing Hard Stone

- Pigment Pilverizer In Tamilnadu

- 采石场防洪方案

- 石子可以制沙吗

- Wheats Greanding Machine In India

- 齿辊破碎机的设计

- 那里有喷射混凝土机器卖

- Leading Stone Crusher Manufacturers In India

- Smaller Vibrating Screens Using Poly Screens

- 东方锆业锆英砂选矿设备?