Ball Mill Drive In Operation

Gearless mill drives Grinding ABB Mining

根据热度为您推荐•反馈

Ball mill Wikipedia

OverviewWorkingApplicationsDescriptionAdvantages of the ball millVarietiesSee also

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

根据热度为您推荐•反馈

Variables in Ball Mill Operation Paul O. Abbe®

Ball milling is one of the few unit operation that improves with increasing mill diameter. If acceptable results can be obtained with a 12” jar mil, then good result will certainly be obtained with a 72” diameter mill.

Ball Mills Mineral ProcessingMetallurgy

Ball Mill Design/Power Calculation Mineral Processing

2015年6月19日Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350

Inching drives one way to improve mill safety Metso

2022年4月11日A large mill could be rotating at 10 to 15 RPM, depending on its size, during normal operation, yet an inching speed of about 1% of operating mill speed (i.e.,

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日The results of the slurry roughness tests by operators at given intervals (after 3, 6, and 9 h ball mill device operation) are reported in linguistic expressions. The mass distribution of...

Ball Mill an overview ScienceDirect Topics

Today, the largest ball mill in operation is 8.53 n is revolutions per minute; η 1, and η 2 are coefficients of efficiency of electric engine and drive, respectively. A feature of ball

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

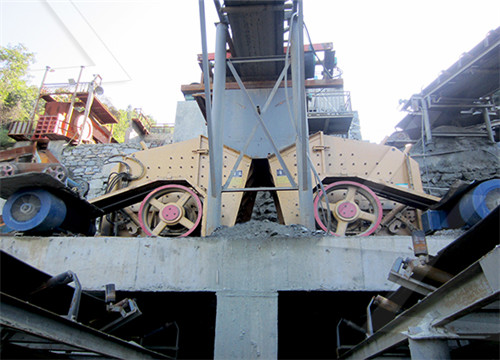

2021年2月26日Analysis of Variant Ball Mill Drive Systems. The basic element of a ball mill is the drum, in which the milling process takes place ( Figure 1 ). The length of the drum in the analyzed mill (without the lining)

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Ball mills ride on steel tires or supported on both ends by trunnions. Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. The prime movers are usually synchronized motors. During

Ring-geared mill drives Grinding ABB Mining

We provide optimized mill drive solutions for all types of ring-geared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and low maintenance operation. Video

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年2月26日Milling is among the most energy-consuming technological stages of copper ore processing. It is performed in mills, which are machines of high rotational masses. The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading. One method for increasing the energy efficiency of ball mills is to optimize

Variables in Ball Mill Operation Paul O. Abbe®

Ball milling is one of the few unit operation that improves with increasing mill diameter. If acceptable results can be obtained with a 12” jar mil, then good result will certainly be obtained with a 72” diameter mill.

Ball Mill Design/Power Calculation Mineral

2015年6月19日The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution. The following shows

Gearless Mill Drives ABB

Antamina Compania Minera Antamina S.A. Peru Project: One SAG Mill and 3 Ball Mill Drive Systems Capacity: SAG Mill 1000 t/h Ball Mills 1000 t/h Consultant: Bechtel, USA Mill Builder: FFE Minerals, USA Mill Size: SAG Mill 38 feet/11,58 m Ball Mills 24 feet/7,32 m Ore processed: Copper/Zinc Drive Rating: SAG Mill 20,1 MW, 9,23 rpm Ball Mills

Ball Mill Drives 911metallurgist

2016年10月22日Ball Mill SPEED REDUCER DRIVE This is essentially a direct connected drive permitting the use of higher speed motors. The motor shaft is connected to the high speed shaft of a reducer by a flexible

AN EXPERIMENTAL ANALYSIS OF VIBRATION OF A BALL

The drive of the ball mill consists of an induction electric motor, two-stage gearbox and the pinion gear. This pinion gear is mated with the girth gear mounted on circumference of the ball mill shell and in that way it transfers the motion from the drive to the shell, see Figure 1, taken from [1]. Figure 1. Mechanical system of a ball mill

Overflow Discharge Ball Mill in Operation- Mineral Processing Ball

2015年6月12日Overflow Discharge Ball Mill in Operation- Mineral Processing Ball mill machine working Himanshu Srivastav 2.98K subscribers Subscribe 39K views 7 years ago Overflow Discharge

(PDF) Technical Evaluation and Practical Experience

2005年6月1日This lack of movement toward larger mills is somewhat surprising since in the same period the drive rating of ball mills for similar duties such as ore grinding has shown an increase in drive

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年3月23日New ball mill drive system with the prototype energy-saving SMH motor [37]. Start-up of the LSPMSM SMH-1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b

Maintenance training for ball and vertical mills

Ball mill operations and maintenance training seminar details The course offers classroom instruction from our ball mill specialists and working exercises to enhance the learning process. This 3-day seminar is designed to train participants on the technology and best practices for maintenance of ball and vertical mills.

The Ultimate Guide to Ball Mills miningpedia.net

2019年8月14日During the operation,the hollow shaft in the center of the ball mill drives the mill body to rotate under the driving of the power system. • Edge driving ball mill: the motor drives the gear on the edge of the cylinder through the reducer to drive the cylinder movement. 6. According to the operation characteristics of ball mill:

Selecting Inching Drives for Mill and Kiln Applications

of the inching reducer drive can be added to reflect efficiency losses. P inch = P inch (1 + (stage 0.01)) where stage is the number of reductions between the inching drive motor and the main drive input shaft (or mill pinion if direct driven) Round up P inch to the next standard motor power. This standard motor power becomes the incher

Ring-geared mill drives Grinding ABB Mining

We provide optimized mill drive solutions for all types of ring-geared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and low maintenance operation. Video

Ball Mill Drives CrushingGrinding Drives David Brown

Walks the walk, talks the torque. Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding applications. Extensively field tested and proven in harsh cement applications, our mill drive gearboxes cover all grinding applications up to 10 MW per drive

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年3月23日New ball mill drive system with the prototype energy-saving SMH motor [37]. Start-up of the LSPMSM SMH-1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

2021年2月26日Milling is among the most energy-consuming technological stages of copper ore processing. It is performed in mills, which are machines of high rotational masses. The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading. One method for increasing the energy efficiency of ball mills is to optimize

Ball Mill Design/Power Calculation Mineral

2015年6月19日The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution. The following shows

Gearless Mill Drives ABB

Antamina Compania Minera Antamina S.A. Peru Project: One SAG Mill and 3 Ball Mill Drive Systems Capacity: SAG Mill 1000 t/h Ball Mills 1000 t/h Consultant: Bechtel, USA Mill Builder: FFE Minerals, USA Mill Size: SAG Mill 38 feet/11,58 m Ball Mills 24 feet/7,32 m Ore processed: Copper/Zinc Drive Rating: SAG Mill 20,1 MW, 9,23 rpm Ball Mills

(PDF) Technical Evaluation and Practical Experience

2005年6月1日This lack of movement toward larger mills is somewhat surprising since in the same period the drive rating of ball mills for similar duties such as ore grinding has shown an increase in drive

AN EXPERIMENTAL ANALYSIS OF VIBRATION OF A BALL

The drive of the ball mill consists of an induction electric motor, two-stage gearbox and the pinion gear. This pinion gear is mated with the girth gear mounted on circumference of the ball mill shell and in that way it transfers the motion from the drive to the shell, see Figure 1, taken from [1]. Figure 1. Mechanical system of a ball mill

Maintenance training for ball and vertical mills

Ball mill operations and maintenance training seminar details The course offers classroom instruction from our ball mill specialists and working exercises to enhance the learning process. This 3-day seminar is designed to train participants on the technology and best practices for maintenance of ball and vertical mills.

Gearless Ball Mill Operation MetallurgistMineral

2019年1月9日The 17 ft. x 56 ft. double compartment ball mill at St. Lawrence Cement Company has the first gearless drive built in North America and has the world’s largest hydrodynamic bearings currently

The Ultimate Guide to Ball Mills miningpedia.net

2019年8月14日During the operation,the hollow shaft in the center of the ball mill drives the mill body to rotate under the driving of the power system. • Edge driving ball mill: the motor drives the gear on the edge of the cylinder through the reducer to drive the cylinder movement. 6. According to the operation characteristics of ball mill:

Selecting Inching Drives for Mill and Kiln Applications

of the inching reducer drive can be added to reflect efficiency losses. P inch = P inch (1 + (stage 0.01)) where stage is the number of reductions between the inching drive motor and the main drive input shaft (or mill pinion if direct driven) Round up P inch to the next standard motor power. This standard motor power becomes the incher

Making remote mines and low ore grades economical and shifting Mining

Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, round-the-clock reliability and the opportunity to mine in remote areas. The six ABB GMDs, which are the most powerful mill drive systems on the market are all now in continuous operation. Two 28 MW gearless

Design and simulation of gear box for stone crushing ball mill

2022年1月1日The details of the ball mill motor are as follows. Power = 12.4 kW or 16.7 HP and the speed is 343 rpm. 3.1. Load calculations (prior to failure analysis) The ball mill can experience failure based on the maximum normal stress theory as the working loads acting in the ball mill is concentrated across the seam of the mill periphery.