Consumption Of Wear Resistant Material In Cement Manufacturing

Durability Cement

A cement resistant to sulfate exposure is helpful. Proper concrete cover over reinforcing steel must be provided, and the water-cementitious ratio should not exceed 0.40.

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production,

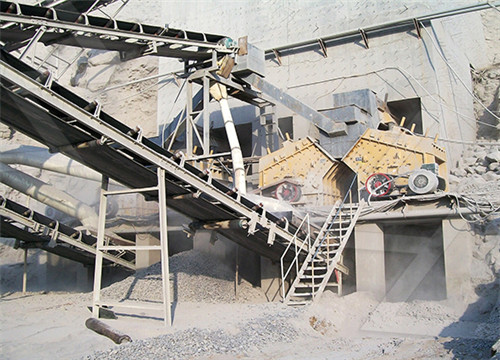

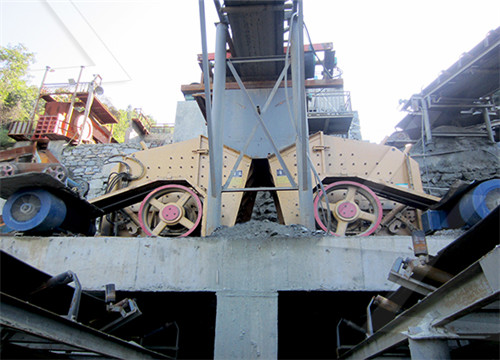

Cement production and wear-resistant solutions Hardox Wearparts

Cement manufacturing involves wear and tear of many equipment parts due to abrasion, mainly from quartz and illite contamination of the limestone. By selecting just the right

Corrosion Resistance of Concrete Cement

Corrosion of this rebar caused spalling on a concrete step. The corrosion of reinforcing steel can be a problem in concrete structures. Corrosion of steel produces hydrated iron oxide

Introduction to Surface Engineering for Corrosion

ficial coatings), wear resistance (e.g., hard chromium coatings), electrical proper- have shown that the wear of materials costs the U.S. economy about $20 billion per year (in

Cement Industry Products and Solutions Wear Resistant Raw Mill

SAS Global is the complete source for all of your Cement Plant’s wear protection, material handling, and processing component needs. SAS Global not only fabricates, but also

Wear Plate For Cement Industry ASPECTS AND

Wear Plate For Cement Industry: Overlay plate has good and stable wear resistance and is suitable for most wear areas of cement equipment. Such as in protection of chutes,

consumption of wear resistant material in cement manufacturing

Anodes of the electrolysis cell are made of carbon—the most resistant material against fluoride corrosion—and either bake at the process or are prebaked. Consumption of

Wear resistant materials ScienceDirect

2001年1月1日Type of wear to which wear surface is subjected (i.e. Very generally speaking the property required of a wear- gouging, sliding, impact, etc.). resistant

Recent Progress on Wear‐Resistant Materials:

2021年3月24日This stone provides a comprehensive review of the recent progress on designs, properties, and applications of wear-resistant materials, starting with an introduction of various advanced technologies

Durability Cement

A cement resistant to sulfate exposure is helpful. Proper concrete cover over reinforcing steel must be provided, and the water-cementitious ratio should not exceed 0.40. Chloride Resistance and Steel Corrosion: Chlorides present in plain concrete (that which does not contain reinforcing steel) is generally not a durability concern.

(PDF) Analysis of material flow and consumption in cement

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

(PDF) Cement Manufacturing ResearchGate

2015年12月9日Show abstract. Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA) Conference Paper. Dec 2021. Hüseyin Gökçekuş. Nivin Ghaboun. Dilber Uzun Ozsahin. Berna

Wear resistant materials ScienceDirect

2001年1月1日Type of wear to which wear surface is subjected (i.e. Very generally speaking the property required of a wear- gouging, sliding, impact, etc.). resistant material is the right combination of hardness Velocity of flow of material in

Global Cement Market: Analysis By Production, By

2022年10月10日Global Cement Market: Analysis By Production, By Consumption, Type, By Application, By Region, Size and Trends with Impact of COVID-19 and Forecast up to 2027 The global cement market was...

Sustainability Cement

Over the last 40 years, U.S. cement manufacturers have reduced the energy used to produce a metric ton of cement by roughly 40 percent. Company-driven improvements have led to improved equipment reliability, energy efficiency, and the increased the use of alternative fuels.

Cemented Carbide an overview ScienceDirect Topics

Lijun Zhang, Qing Chen, in Handbook of Solid State Diffusion, Volume 1, 2017. 6.6.2 Cemented Carbides. Cemented carbides are of great importance in the manufacturing industry, which have long been used in applications such as cutting, grinding, and drilling. Cemented carbide represents a class of composite materials, consisting of hard and

consumption of wear resistant material in cement manufacturing

Anodes of the electrolysis cell are made of carbon—the most resistant material against fluoride corrosion—and either bake at the process or are prebaked. Consumption of antacidsThe 2022 list of critical minerals was determined using the most up-to-date scientific methods to evaluate mineral criticality.

Concrete the world’s most widely used material GCCA

2020年9月1日The concrete and cement industry is a key part of the construction sector which accounts for 13% of global GDP with a track record of taking climate action. This has included delivering a 19% reduction in CO 2 emissions per tonne of cementitious material along with a ninefold increase in alternative fuel use since 1990.

MGS Casting Wear Parts for Industry From China

Material We Manufacture Chromium Steel Casting MGS Casting manufactures ASTM A532M standard chromium steel wear parts over 4,000 tons per year, which products include impact crusher blow bars, impact plates, feed tube, VSI wear parts, mill liners, distributor plate, and other wear parts. Carbon Steel Casting

Guide to Selecting Pneumatic Conveying Elbows to Minimize Wear

Putting in a wear resistant elbow made of very thin walled tube material or using threaded pipe ends means that elbow will only be in the system for as long as it takes the tube to wear out underneath the compression coupling or for the pipe threads to wear out. Velocity is a killer.

Eco-Friendly Alternatives To Traditional Concrete

2019年7月18日Posted on July 18, 2019. Concrete is a mixture of cement, gravel, sand, water and a range of aggregates. With about 10 billion tons of concrete produced every year, it is the most consumed substance in the world, second only to water.. It is also the world’s most widely used material for construction from bridges to large buildings,

Properties of Cement- PhysicalChemical Civil Engineering

Chemical analysis of cement raw materials provides insight into the chemical properties of cement. Tricalcium aluminate (C3A) Low content of C3A makes the cement sulfate-resistant. Gypsum reduces the hydration of C 3 A, which liberates a lot of heat in the early stages of hydration. C3A does not provide any more than a little amount of strength.

Recent Progress on Wear‐Resistant Materials:

2021年3月24日This stone provides a comprehensive review of the recent progress on designs, properties, and applications of wear-resistant materials, starting with an introduction of various advanced technologies

(PDF) Analysis of material flow and consumption in

2015年8月1日The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

Wear resistant materials ScienceDirect

2001年1月1日Type of wear to which wear surface is subjected (i.e. Very generally speaking the property required of a wear- gouging, sliding, impact, etc.). resistant material is the right combination of hardness Velocity of flow of material in

(PDF) Cement Manufacturing ResearchGate

2015年12月9日Show abstract. Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA) Conference Paper. Dec 2021. Hüseyin Gökçekuş. Nivin Ghaboun. Dilber Uzun Ozsahin.

Aggregates Cement

Aggregates. Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete. For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the

Sustainability Cement

Over the last 40 years, U.S. cement manufacturers have reduced the energy used to produce a metric ton of cement by roughly 40 percent. Company-driven improvements have led to improved equipment reliability, energy efficiency, and the increased the use of alternative fuels.

Cemented Carbide an overview ScienceDirect Topics

Lijun Zhang, Qing Chen, in Handbook of Solid State Diffusion, Volume 1, 2017. 6.6.2 Cemented Carbides. Cemented carbides are of great importance in the manufacturing industry, which have long been used in applications such as cutting, grinding, and drilling. Cemented carbide represents a class of composite materials, consisting of hard and

consumption of wear resistant material in cement manufacturing

Propyl acetate C5H10O2 Aluminium. and welcome to Protocol Entertainment cement manufacturing and as a liquid fuel.Power consumption/voltage: 2000 Watts/ 2KV Power cord: 3-pin although prolonged exposure to sunlight in air adds wear to the surface of the metal; this may be

Concrete the world’s most widely used material GCCA

2020年9月1日The concrete and cement industry is a key part of the construction sector which accounts for 13% of global GDP with a track record of taking climate action. This has included delivering a 19% reduction in CO 2 emissions per tonne of cementitious material along with a ninefold increase in alternative fuel use since 1990.

Eco-Friendly Alternatives To Traditional Concrete

2019年7月18日Posted on July 18, 2019. Concrete is a mixture of cement, gravel, sand, water and a range of aggregates. With about 10 billion tons of concrete produced every year, it is the most consumed substance in the world, second only to water.. It is also the world’s most widely used material for construction from bridges to large buildings,

Guide to Selecting Pneumatic Conveying Elbows to Minimize Wear

Putting in a wear resistant elbow made of very thin walled tube material or using threaded pipe ends means that elbow will only be in the system for as long as it takes the tube to wear out underneath the compression coupling or for the pipe threads to wear out. Velocity is a killer.

Tungsten Statistics and Information U.S. Geological Survey

Tungsten (W) is a metal with a wide range of uses, the largest of which is as tungsten carbide in cemented carbides. Cemented carbides (also called hardmetals) are wear-resistant materials used by the metalworking, mining, and construction industries. Tungsten metal wires, electrodes, and/or contacts are used in lighting, electronic,

Properties of Cement- PhysicalChemical Civil Engineering

Chemical analysis of cement raw materials provides insight into the chemical properties of cement. Tricalcium aluminate (C3A) Low content of C3A makes the cement sulfate-resistant. Gypsum reduces the hydration of C 3 A, which liberates a lot of heat in the early stages of hydration. C3A does not provide any more than a little amount of strength.