Crusher Copper Ore Process In Australia

Processing Citic Pacific Mining

2022年10月27日We have four in-pit crushers, each standing seven stories high and able to crush more than 4,000 tonnes of ore an hour these are the largest in-pit crushers in Australia. The crushers deposit the ore onto one of two overland conveyors, each

Copper Geoscience Australia

IntroductionPropertiesUsesHistoryFormationResourcesMiningProcessing

At some Australian mines, the copper is leached from the ore to produce a copper-rich solution which is later treated to recover the copper metal. The ore is first broken and set out on leach pads where it is dissolved by a sulfuric acid solution to leach out the copper. The copper-rich solution is then pumped to the solvent extraction plant to sep...

Copper ore processing in Queensland, Australia

2012年11月20日It is planned to mine and process existing resources in one of the technically most advanced processing plants in the world. During the first years, the

Copper Ore Mining in Australia Industry Data, Trends, Stats

Copper Ore Mining in Australia industry outlook (2022-2027) poll Average industry growth 2022-2027: This percentage represents tangible assets held for sale in the ordinary

Mineral processing Wikipedia

OverviewHistoryUnit operationsOther processesConferencesSee alsoNotesSources

In the field of extractive metallurgy, mineral processing is the process of separating commercially valuable minerals from their ores. Depending on the processes used in each instance, it is often also known as ore dressing or ore milling.

Copper Mining and Processing: Processing Copper Ores

A. Processing of Oxide Ore Oxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary

Copper Processing Equipment, Process Flow, Cases

2019年8月23日Copper ore processing. According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide.

Copper Ore Processing Solution Eastman Rock Crusher

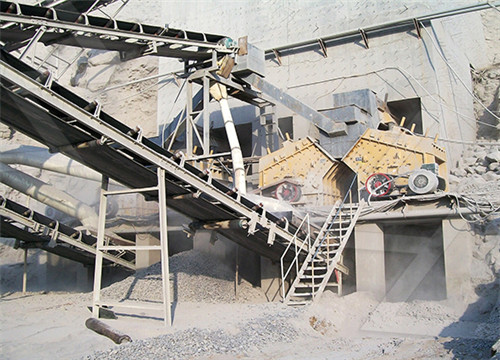

Copper ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation. In the crushing process, three-stage closed-circuit crushing is a modern method suitable for high

Copper Ore Crushing Production Line, Mobile Crusher

Crushing is the first size reduction stage in copper production operation; it aims to reduce the large lumps of raw materials into small particles preparing for further operation. Large

Iron Bridge Magnetite Project, Australia Mining

2020年11月2日The plant will employ the KB 63-130 type gyratory crushers, which will be the largest crushers in the country. The crushers will be used to process raw iron ore

Copper extraction Wikipedia

Copper smelting technology gave rise to the Copper Age, aka Chalcolithic Age, and then the Bronze Age. The Bronze Age would not have been possible without the development of smelting technology. The modern froth flotation process was independently invented in the early 1900s in Australia by C.V Potter and around the same time by G. D. Delprat.

Crushing Metso Outotec

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications. Contact our sales experts Increase capacity

Underground hard-rock mining Wikipedia

Underground hard-rock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead.It also involves the same techniques used to excavate ores of gems, such as diamonds and rubies. Soft-rock mining refers to the

Crusher an overview ScienceDirect Topics

The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product. The size is usually between 0.5 and 2 cm in diameter so that it is suitable for grinding. Secondary crushers

First Quantum Minerals Ltd. Our Operations

Ore processing includes three stages of crushing primary and secondary ball mill grinding, conventional flotation using either standard or column cells, and water removal by thickening and pressure filtering to produce copper and zinc concentrates.

MetallurgistMineral Processing Engineer

MetallurgistsMineral Processing Engineers. 11 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues. Although improvements to the metallurgical processes

Crushing SpringerLink

Abstract. The size to which particles are reduced is governed by three criteria: the particle size of the mineral grains in an ore which are to be liberated for later separation and collection into a concentrate; and. the exposure of mineral grains for dissolution by a leaching process which is to follow.

Complete Set of Processing Equipment for Copper Ore

After mining, copper mines often needs to go through various processing and then use. The following introduces the complete set of copper ore processing equipment, that is, the composition of each equipment in the copper ore process flow. Copper ore processing equipment 1. Crusher: Copper ore, as a valuable metal ore with economic value, is

Iron ore BHP

Iron ore is mixed with coke (from super-heated metallurgical coal) in a blast furnace. Heating Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag.

Copper ore crusher mining process in Peru sbmchina

Copper ore crusher is as important crushing equipment during copper ore processingin Peru.We need choose the most appropriate coppercrusher which should be based on the performance of copper ore. This article focuses on introducingcopper ore crushing proc. Asia Pacific; 中国大陆-简体中文; Australia—English;

What are the specifications of the copper crusher?

2023年2月10日copper ore crushers A copper crusher is a type of pressure gauge that is used in firearms to measure the pressure of a cartridge during firing. The copper crusher works by measuring...

Jaw Crusher Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks,gravel,sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material.

What machine is used to crush copper ore? linkedin

2023年2月15日Jaw Crusher: This machine uses a compressive force to break down the copper ore into smaller pieces. The ore is fed into the top of the crusher and is crushed between two jaws. Cone...

Primary Crusher an overview ScienceDirect Topics

Crushing to the proper size usually occurs in stages because rapid size reduction, accomplished by applying large forces, commonly results in the production of excessive fines (Rollings and Rollings 1996 ). After primary crushing, the material is run through one or more secondary crushers.

Copper extraction Wikipedia

Copper smelting technology gave rise to the Copper Age, aka Chalcolithic Age, and then the Bronze Age. The Bronze Age would not have been possible without the development of smelting technology. The modern froth flotation process was independently invented in the early 1900s in Australia by C.V Potter and around the same time by G. D. Delprat.

Copper Ore Mining in Australia Industry Data, Trends, Stats

Copper Ore Mining in Australia industry outlook (2022-2027) poll Average industry growth 2022-2027: This percentage represents tangible assets held for sale in the ordinary course of business, or goods in the process of production for such sale, or materials to be consumed in the production of goods and services for sale.

BHP OPERATIONAL REVIEW FOR THE YEAR ENDED 30

2020年7月21日2020 financial year, BHP had six major projects under development in petroleum, copper, iron ore and potash, with a combined budget of US$11.4 billion over the life of the projects. Our major projects under development in petroleum In Australia, we have only had a small number of cases among our workforce since COVID-19 began,

Underground hard-rock mining Wikipedia

Underground hard-rock mining refers to various underground mining techniques used to excavate "hard" minerals, usually those containing metals, such as ore containing gold, silver, iron, copper, zinc, nickel, tin, and lead.It also involves the same techniques used to excavate ores of gems, such as diamonds and rubies. Soft-rock mining refers to the

First Quantum Minerals Ltd. Our Operations

Ore processing includes three stages of crushing primary and secondary ball mill grinding, conventional flotation using either standard or column cells, and water removal by thickening and pressure filtering to produce copper and zinc concentrates.

MetallurgistMineral Processing Engineer

MetallurgistsMineral Processing Engineers. 11 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues. Although improvements to the metallurgical processes

Crushing SpringerLink

Abstract. The size to which particles are reduced is governed by three criteria: the particle size of the mineral grains in an ore which are to be liberated for later separation and collection into a concentrate; and. the exposure of mineral grains for dissolution by a leaching process which is to follow.

MetallurgyMineral Processing Over 10000 Members and

All aspects of crushing, ore conveying and screening operation and maintenance: Discuss any type of crushers: gyratory, jaw, cone, roll, HPGR, impact, hammer, etc. Crusher liner, lubrication, mantle, bowl, spider and all other components.Ore transportation on conveyor belts and through classification systems such as vibrating screens, grizzlies and feeders.

Complete Set of Processing Equipment for Copper Ore

After mining, copper mines often needs to go through various processing and then use. The following introduces the complete set of copper ore processing equipment, that is, the composition of each equipment in the copper ore process flow. Copper ore processing equipment 1. Crusher: Copper ore, as a valuable metal ore with economic value, is

Copper ore crusher mining process in Peru sbmchina

Copper ore crusher is as important crushing equipment during copper ore processingin Peru.We need choose the most appropriate coppercrusher which should be based on the performance of copper ore. This article focuses on introducingcopper ore crushing proc. Asia Pacific; 中国大陆-简体中文; Australia—English;

sbmchina/sbm copper ore to copper manufacturing process.md

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

10tph manganese ore processing plant walker

2021年9月2日The output size of the jaw crusher can be adjusted to 20-80mm, the size you want is 60mm, you can adjust the output size to 60mm, the capacity of the jaw crusher can be 10-15tph. the motor can be customized as you required with an additional cost 200USD for each customized motor(our normal motor is free, please kindly notes) 16.

Copper Beneficiation Process JXSC Mineral

The main process of copper ore flotation is rough as follows: ore crushing and screening → stage grinding stage flotation → concentration and dehydration → copper concentrate. The material is fed to the rough jaw crusher by a feeder and then send to the fine jaw crusher for the second crushing. After the crushing, the material is going to

Nickel Geoscience Australia

Source: Geoscience Australia. Western Australia has the largest nickel resources with 96% of total Australian resources, contained within nickel sulfide and lateritic nickel deposits. Queensland is the second largest with 4.5% (lateritic nickel), followed by Tasmania with 0.2%. Currently, all nickel is accessible for mining.