How Many Part Of Crusher Machine

Jaw Crushers McLanahan

The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road

Type of crushers and their difference JXSC Mining

根据热度为您推荐•反馈

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

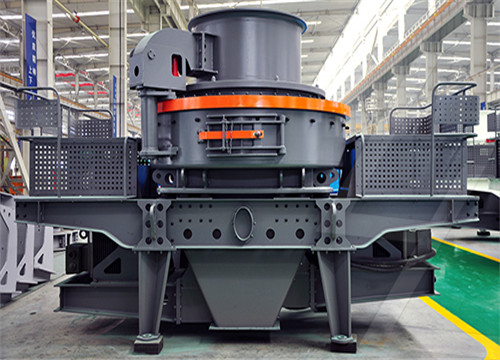

Crusher Machine For Sale Types Of Crushing Machines

AIMIX mainly can supply you with crusher machine types: jaw crusher, cone crusher, impact crusher, and hammer crusher. Let’s see them one by one. Primary Crushing

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

“You might have too many fines going into the crusher, which means you have a screening problem—not a crushing problem,” he says. “Also, you want to choke feed the crusher

4 Types of Stone Crushers' Maintenance and Efficient

2023年2月15日When the sand making machine is working for 400 hours, it should be added with the proper amount of grease. When the work time reaches 2000 hours, the spindle assembly should be opened to clean

The Machines (professional wrestling) Wikipedia

The Machines were a professional wrestling stable who performed in the World Wrestling Federation in 1986. The team consisted of well-known WWF wrestlers working under

Extreme powerful crusher machines fast crushing

2020年6月22日Extreme powerful crusher machines fast crushing everything for new recycle. Shredder ! #2 D.Machinery 961K subscribers Subscribe 10M views 2 years ago Extreme powerful

Crusher an overview ScienceDirect Topics

Chamber sizes vary between 3-6 numbers within a particular designated crusher size to produce fine, medium or coarse sized product. The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These crushers are invariably operated in closed circuit.

Type of crushers and their difference JXSC Mining

2019年12月10日Inside the jaw crusher, is consisting of two vertical jaws installed to a V form, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to

(PDF) Design of Impact stone crusher machine

2019年5月31日Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher. Impact...

Design and Construction of Rock Crushing Machine from

Components of jaw crusher In this machine, various parts (components) are inter-linked together by bolting, welding and trapping (confining) to build a functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

“According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs,” says Erik Schmidt, Resource Development Manager, Johnson Crushers International, Inc. “That’s a pretty large factor towards the overhead of that equipment.

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

the bottom part by removing the base plate of the bin and can be transported just as it is to the recycling plants. 4. CRUSHERS Nowadays, waste management is one of the areas time, a can crusher machine using crank and slotted lever mechanism having high crushing ability can be employed.

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP. Naturally these two hard surfaces of crusher are critical parts. One of these surfaces are known as grinding plates and other may known as rings, hammers, etc.

Impact Crusher With Capacity Of 15-350 Tons Per Hour

Spare parts supply: 12 Months Guarantee. After sale Service: Life-long Service. Price: Reasonable. Market: standard container China quarry mining machine stone impact crusher Port qingdao port Lead time : Quantity(Sets) 1 10 >10: Lead time (days) 30: To be negotiated: Xxnx Impact Crusher With Capacity Of 35-50 Tons Per Hour . Product

China KSD Cone Crusher Parts Manufacturers, Factory, Suppliers

Hangzhou City, Zhejiang Province, China. [email protected] +. KSD Cone Crusher Parts. Support bowl body N-1277.04.302

Development of an automatic can crusher using

2019年6月1日The average result of empty can could shrink from 31% to 60 % of the original value, by using the attuned and compatible pressure for this system. The connection between the cylinder, valve, roller...

Crusher Machine for Sale for aggregate crushing

Crusher machine for sale is a kind of equipment specially designed for producing sand and gravel aggregate. The crusher equipment can be used in many construction projects. For the function of crusher machine is to

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact.

5 Glass Crushers to Accelerate Your Glass Recycling

2023年2月15日There are five types of glass crushers: jaw crusher, hammer crusher, roll crusher, impact crusher, and compound crusher . Starting from the above five types of glass crushers, this article will analyze the advantages and disadvantages of these glass crushing machines to help you choose the suitable glass crusher. 1. Glass jaw crusher

jaw crusher discharge size

2023年3月10日A jaw crusher is a versatile and popular crushing machine used in many different industries, including mining, construction, and demolition. One of the key benefits of a jaw crusher is that it can

(PDF) Design of Impact stone crusher machine

2019年5月31日Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher. Impact...

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

“According to leading aggregate producers, repairs and maintenance labor average 30 to 35 percent of direct operating costs,” says Erik Schmidt, Resource Development Manager, Johnson Crushers International, Inc. “That’s a pretty large factor towards the overhead of that equipment.

Design and Construction of Rock Crushing Machine from

Components of jaw crusher In this machine, various parts (components) are inter-linked together by bolting, welding and trapping (confining) to build a functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher.

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

the bottom part by removing the base plate of the bin and can be transported just as it is to the recycling plants. 4. CRUSHERS Nowadays, waste management is one of the areas time, a can crusher machine using crank and slotted lever mechanism having high crushing ability can be employed.

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size of coal affects the performance of CHP. Naturally these two hard surfaces of crusher are critical parts. One of these surfaces are known as grinding plates and other may known as rings, hammers, etc.

Crusher inspections Metso Outotec

More thorough and specialized inspections should then be conducted by Metso Outotec experts. 1000-hour Operating Inspection: up to two hours with the equipment operating and about 4-6 hours shutdown depending

Crusher Machine for Sale for aggregate crushing

The crushing equipment for sale has three types: jaw crusher, cone crusher and impact crusher. The aggregate jaw crusher is mainly used for the stage of coarse crushing, that is to say the primary crushing

Impact Crusher With Capacity Of 15-350 Tons Per Hour

Spare parts supply: 12 Months Guarantee. After sale Service: Life-long Service. Price: Reasonable. Market: standard container China quarry mining machine stone impact crusher Port qingdao port Lead time : Quantity(Sets) 1 10 >10: Lead time (days) 30: To be negotiated: Xxnx Impact Crusher With Capacity Of 35-50 Tons Per Hour . Product

Design and Development of a Plastic Bottle Crusher IJERT

Abstract—A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces. Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in the purpose intended to. Crushing is the process of transferring a

China KSD Cone Crusher Parts Manufacturers, Factory, Suppliers

Hangzhou City, Zhejiang Province, China. [email protected] +. KSD Cone Crusher Parts. Support bowl body N-1277.04.302

Development of an automatic can crusher using

2019年6月1日The average result of empty can could shrink from 31% to 60 % of the original value, by using the attuned and compatible pressure for this system. The connection between the cylinder, valve, roller...

5 Glass Crushers to Accelerate Your Glass Recycling

2023年2月15日There are five types of glass crushers: jaw crusher, hammer crusher, roll crusher, impact crusher, and compound crusher . Starting from the above five types of glass crushers, this article will analyze the advantages and disadvantages of these glass crushing machines to help you choose the suitable glass crusher. 1. Glass jaw crusher

Car Crusher OverBuilt

PartsService. Parts; Press Brake Services; Financing; About Us; Contact; 1.800.548.6469 service@overbuilt. Home; Equipment. Car Crusher About Us; Contact; OVERBUILT CAR CRUSHER. Built standard with its 10 foot opening the OverBuilt Car Crusher has the highest opening on the market. In addition, it has a remarkable 159

Jaw Crusher Explained saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks,gravel,sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material. Waste material can be discarded or