Semi Autogenous Mill In Malaysia

Semi-autogenous mill power prediction by a hybrid

2018年5月5日There are few methods of semi-autogenous (SAG) mill power prediction in the full-scale without using long experiments. In this work, the effects of different

Semi-Autogeonous (SAG) Mill Overload Forecasting

2022年1月13日1 Introduction. In mining, a Semi-Autogenous Grinding mill (SAG) is the equipment used at mineral processing plants in the size reduction process, making the

进一步探索

Influence of feed size on AG / SAG mill performance ReOptimizing your SAG mill operation International Mining根据热度为您推荐•反馈

SAG Mill Autogenous and Semi-Autogenous Mills

根据热度为您推荐•反馈

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日These are known as semi-autogenous grinding (SAG) mills. In the mining industry all of these types of mills are in use. The disintegration and size reduction of

Mill (grinding) Wikipedia

OverviewGrinding machinesGrinding lawsTypes of grinding millsSee alsoExternal links

In materials processing a grinder is a machine for producing fine particle size reduction through attrition and compressive forces at the grain size level. See also crusher for mechanisms producing larger particles. In general, grinding processes require a relatively large amount of energy; for this reason, an experimental method to measure the energy used locally during milling with di

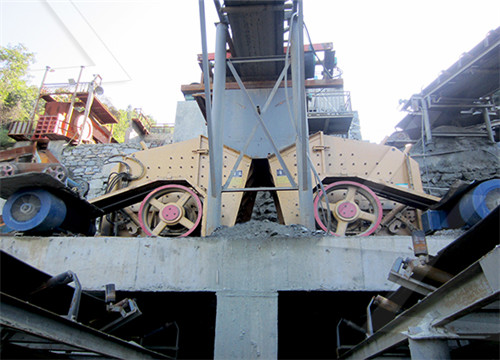

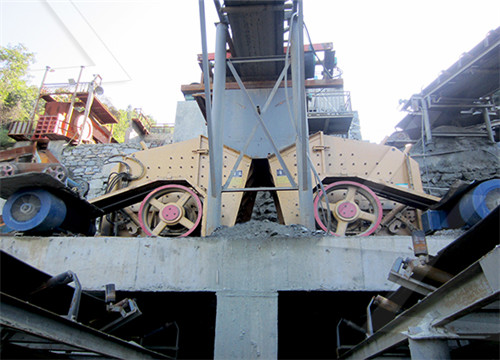

Semi Autogenous Mill SAG Mills For Sale AGICO SAG

The semi-autogenous mill is a new type of grinding equipment with both crushing and grinding functions. It has the advantages of simple process flow, small investment, short construction cycle, and easy operation. It

Autogenous GrindingSemi Autogenous Grinding Circuits

2017年7月20日Autogenous GrindingSemi Autogenous Grinding Circuits Size reduction is the most expensive operation in most mills. Crushing and grinding usually require the greatest portion of capital costs

Semi Autogenous Grinding (SAG) Mill For Sale, Sag Mining CIC

SAG Mill Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screening. SAG

AG Autogenous Grinding Mineral ProcessingMetallurgy

2015年8月6日In conventional mills the diameter of the mill is smaller than its length. In autogenous mills the diameter is greater than the length. They can be as much as 40+ feet in diameter. Patented in 1959, AG Mills are

Autogenous and Semi-Autogenous Mills Henan Deya Machinery

2012年7月30日Autogenous (AG) and Semi-Autogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations. These

Semi-autogenous mill power prediction by a hybrid neural

2018年5月5日There are few methods of semi-autogenous (SAG) mill power prediction in the full-scale without using long experiments. In this work, the effects of different operating parameters such as feed moisture, mass flowrate, mill load cell mass, SAG mill solid percentage, inlet and outlet water to the SAG mill and work index are studied.

Semi-Autogeonous (SAG) Mill Overload Forecasting SpringerLink

2022年1月13日In mining, a Semi-Autogenous Grinding mill (SAG) is the equipment used at mineral processing plants in the size reduction process, making the ore suitable for the next stage of flotation.

A Dynamic Model for a Class of Semi-Autogenous Mill Systems

2020年5月25日Abstract: In this , we develop a state space model of semi-autogenous (SAG) mill systems, which is of great significance to the mineral processing control. According to the practical enterprise production condition, the model is composed of two main parts. One is the ore circuit model. Compared with other models of ore circuit,

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

Semi Autogenous Grinding (SAG) Mill For Sale, Sag Mining CIC

The filling rate of steel ball in the shell of the semi-autogenous mill is a main item to distinguish SAG mill and autogenous mill. In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%.

The study of the lining layer abrasing wear in the semi

abrasing wear of the lining of the semi-autogenous grinding mills and the impact of wear-abrasing on the technical parameters of the milling process. In work [9] the effect of lining liners wear on the productivity of the mill was studied. An analysis of fully worn and new inserts-lifters was conducted, as it was in line with the

Autogenous and Semi-Autogenous Mills Henan Deya

2012年7月30日Autogenous (AG) and Semi-Autogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations. These mills typically have a large diameter relative to their length, typically in the ratio or 2 or 2.5 to 1. AG mills employ ore as the grinding media. However, one the challenges with AG

What is a Semi-Autogenous Mill? ballmillssupplier

Semi-autogenous mills, also known as SAG mills, are used in various industries such as mining, mineral processing, and cement manufacturing. These types of mills use a combination of grinding balls, like a ball mill, and larger rocks or ore fragments as grinding media. What is a Semi-Autogenous Mill?

AG/SAG Model Structure after (Leung, 1987).

In spite of the important advances in modelling and simulation of autogenous and semi-autogenous grinding made in recent decades (Napier-Munn et al., 1996;Morrell, 2004), risks exist in...

Semi-autogenous mill power model development using gene expression

2017年2月15日Mill powers of the semi-autogenous mill have an effective influence on the mill performance. In this regard, a new predictive model based on gene expression programming (GEP) was developed to predict the mill power of the SAG mill. To achieve this purpose, a total number of 186 full-scale SAG mill works were investigated and the

Design of a typical Autogenous Mill: Part-II

2013年12月23日An Autogenous Milling defined as used in this study; the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill...

Tube mills for dry grinding. Polysius

3 A 6.2 m x 20 m mill shell on its way from France to Malaysia. With an extensive range of grinding systems, consisting of x tube mills, x rod mills, x autogenous and semi-autogenous mills, x AEROFALL mills, x roller mills and x POLYCOM® high-pressure grinding rolls including x separators, x cement coolers, x dryers and x expert systems for

semi-autogenous mills 英中 Linguee词典

maintenance of the semi-autogenous grin ding ( SAG) mill in t he first. [...] quarter. mmg. mmg. 已處理礦石量受到礦石硬度以及 第一季度計 劃外進行 半自磨機 (SAG)維 護影 響。. mmg. mmg. ( e) Autogenous igni tion temperature.

Semi-autogenous grinding (SAG) mill liner design and development

2007年8月1日SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computer-based modeling of charge motion in SAG mills and on established good design practice. Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, i.e., the impact

Semi-autogenous mill power model development using gene expression

2017年2月15日Mill powers of the semi-autogenous mill have an effective influence on the mill performance. In this regard, a new predictive model based on gene expression programming (GEP) was developed to predict the mill power of the SAG mill. To achieve this purpose, a total number of 186 full-scale SAG mill works were investigated and the

(PDF) Operation Analysis of a SAG Mill under Different

2020年10月9日the qualified particle size at the discharge port of the semi autogenous mill, and the qualified particle. size is defined as no more than 25 mm. The simulation process is shown in Figure 5.

A Dynamic Model for a Class of Semi-Autogenous Mill Systems

2020年5月25日Abstract: In this , we develop a state space model of semi-autogenous (SAG) mill systems, which is of great significance to the mineral processing control. According to the practical enterprise production condition, the model is composed of two main parts. One is the ore circuit model. Compared with other models of ore circuit,

Tube mills for dry grinding. Polysius

3 A 6.2 m x 20 m mill shell on its way from France to Malaysia. With an extensive range of grinding systems, consisting of x tube mills, x rod mills, x autogenous and semi-autogenous mills, x AEROFALL mills, x roller mills and x POLYCOM® high-pressure grinding rolls including x separators, x cement coolers, x dryers and x expert systems for

Mineral Processing Design and Operations ScienceDirect

The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described.

Semi Autogenous Grinding (SAG) Mill For Sale, Sag Mining CIC

The filling rate of steel ball in the shell of the semi-autogenous mill is a main item to distinguish SAG mill and autogenous mill. In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%.

The study of the lining layer abrasing wear in the semi

abrasing wear of the lining of the semi-autogenous grinding mills and the impact of wear-abrasing on the technical parameters of the milling process. In work [9] the effect of lining liners wear on the productivity of the mill was studied. An analysis of fully worn and new inserts-lifters was conducted, as it was in line with the

Autogenous and Semi-Autogenous Mills Henan Deya

2012年7月30日Autogenous (AG) and Semi-Autogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations. These mills typically have a large diameter relative to their length, typically in the ratio or 2 or 2.5 to 1. AG mills employ ore as the grinding media. However, one the challenges with AG

What is a Semi-Autogenous Mill? ballmillssupplier

Semi-autogenous mills, also known as SAG mills, are used in various industries such as mining, mineral processing, and cement manufacturing. These types of mills use a combination of grinding balls, like a ball mill, and larger rocks or ore fragments as grinding media. What is a Semi-Autogenous Mill?

AG/SAG Model Structure after (Leung, 1987).

In spite of the important advances in modelling and simulation of autogenous and semi-autogenous grinding made in recent decades (Napier-Munn et al., 1996;Morrell, 2004), risks exist in...

semi-autogenous mills 英中 Linguee词典

maintenance of the semi-autogenous grin ding ( SAG) mill in t he first. [...] quarter. mmg. mmg. 已處理礦石量受到礦石硬度以及 第一季度計 劃外進行 半自磨機 (SAG)維 護影 響。. mmg. mmg. ( e) Autogenous igni tion temperature.

Semi-Autogenous Grinding (SAG) Mill Liner Supplier

Mill Type: Semi-Autogenous Grinding Mill, AG Mill,Ball Mill. Material: Cr Mo Alloy Steel, High Manganese Steel,rubber compound. Grade: AS2074 L2A/ AS2074 L2B/ AS2074 L2C. Customization: Customizable. Minimum order quantity: 2 pieces. Hardness: more than HRC60. Impact value: about 60J without nortch test bar.

Semi-autogenous grinding (SAG) mill liner design and development

2007年8月1日SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computer-based modeling of charge motion in SAG mills and on established good design practice. Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, i.e., the impact

Semi-autogenous grinding (SAG) mill liner design and

2007年8月1日SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computer-based modeling of charge motion in SAG mills and on established good design practice. Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, i.e., the impact