Cone Crusher Liners Lead-Zinc Types Of Crusher Used In Mining

Cone Crusher an overview ScienceDirect Topics

The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These

Cone Crusher Liners: How to Select and When to Change

根据热度为您推荐•反馈

Crusher Liners Cone Crusher Liners Crushing Wear Parts

932 行Crusher Liners. CSP is a leading supplier of cast, forged, and

Bowl LinerMantle Premium Manganese Liners GTEK

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and

Cone Crusher Explained saVRee

Crusher Types There are three common crushers used at mining and processing plants: Gyratory Crushers Jaw Crushers Cone Crushers Typically, the initial crushing stage is completed using either gyratory

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of

5 Types of Cone Crushers Comparison JXSC Machine

2019年10月9日The multi-cylinder hydraulic cone crusher is used to reduce the number of crushing stages and reduce investment. The needle-like content is generally below 15%. Crush hard rock, choose multi

Material Used For Crusher Liners Qiming Machinery

2020年8月30日Cone Crusher Liners. The chamber of cone crusher is lined with wear parts, namely the mantle and bowl liners. Both liners are made of manganese steel that can crush the hardest material in no time.

Crusher Liners H-E Parts

CME™ Crusher Liners. H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Crusher Liners World-Leading Crusher Liners CMS

Crusher Liners by CMS Cepcor® Our premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve and often exceed the performance of the

Crusher Liners Cone Crusher Liners Crushing Wear

Crusher Liners. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years’ experience supplying crushing wear parts to global mining and

Downstream Crushing Options for Secondary,

2021年4月12日Cone Crushers are the most common types of tertiary and quaternary crushers, though Vertical Shaft Impactors and Roll Crushers can also be used depending on the application. Short-Head

Cone Crusher Explained saVRee

Crusher Types There are three common crushers used at mining and processing plants: Gyratory Crushers Jaw Crushers Cone Crushers Typically, the initial crushing stage is completed using either gyratory

Real-Time Optimization of Cone Crushers Semantic

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation

5 Types of Cone Crushers Comparison JXSC Machine

2019年10月9日The multi-cylinder hydraulic cone crusher is used to reduce the number of crushing stages and reduce investment. The needle-like content is generally below 15%. Crush hard rock, choose multi

Material Used For Crusher Liners Qiming Machinery

2020年8月30日Cone Crusher Liners. The chamber of cone crusher is lined with wear parts, namely the mantle and bowl liners. Both liners are made of manganese steel that can crush the hardest material in no time.

Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher

Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher Spare Parts, Find Details and Price about Cone Crusher Wear Parts Cone Crusher Parts from Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher Spare Parts Grand Heavy Machinery Co., Ltd Home Product Directory ManufacturingProcessing Machinery Mining Machinery

What is CS420 CS660 CS820 Cone Crusher Parts Bowl Liner and

What is CS420 CS660 CS820 Cone Crusher Parts Bowl Liner and Mantle, Metso Cone Crusher Parts Process manufacturerssuppliers on Video Channel of Made-in-China.

Cone Crusher Liners Symons 3FT 4FT 4.25FT GTEK

4830-0023 Bowl Liner 4FT SHD. New GTEK MINING™ part suitable for Symons Cone Crusher. Manufactured by GTEK™. OEM® Part Number 4830-0023. Suits model Symons 4FT SHD. Mn18Cr2 / XT710. Net Weight 661kg. GTEK™ crusher parts are manufactured and warranted by GTEK™. 4830-0023 Bowl Liner 4.25FT STD.

Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner

Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner Casting for Stone Cone Crusher Replacement Wear Parts,Cone Crusher Wear Parts, Cone Crusher Parts についての詳細を検索 Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner Casting for Stone Cone Crusher Replacement Wear Parts Grand Heavy Machinery Co., Ltd より

Our Range of Trio® Cone Crushers Weir The Weir Group

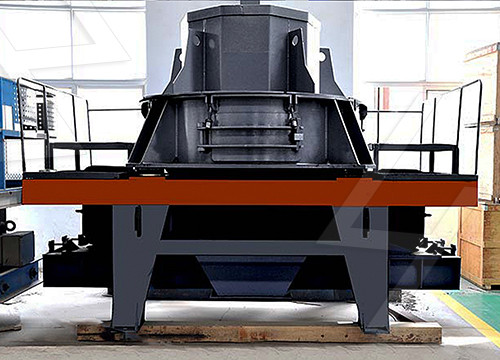

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

All crusher types for your reduction needs Metso Outotec

Cone crushers are often used for intermediate crushing, due to their high capacity and low operating costs. Fine crushing Fine crushing with different types of crushers Fine crushing with cone crushers Due to their design, cone crushers are generally a more expensive investment than impactors are.

Crusher Liners World-Leading Crusher Liners CMS

The metallurgy for CMS Cepcor® premium mining range manganese liners has been developed in partnership with our foundry partner who is renowned to be the world’s leading manufacturer of crusher liners.

Our Range of Trio® Cone Crushers Weir The Weir Group

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Crusher Liners Cone Crusher Liners Crushing Wear

Crusher Liners. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years’ experience supplying crushing wear parts to global mining and

Downstream Crushing Options for Secondary,

2021年4月12日Occasionally, a Jaw Crusher may be applied as a secondary crusher. Cone Crushers. Cone Crushers are compression-type crushers, which reduce material as it advances downward through

Real-Time Optimization of Cone Crushers Semantic

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation

Material Used For Crusher Liners Qiming Machinery

2020年8月30日Cone Crusher Liners. The chamber of cone crusher is lined with wear parts, namely the mantle and bowl liners. Both liners are made of manganese steel that can crush the hardest material in no time.

CME™ Crusher Liners H-E Parts

CME™ Crusher Liners. H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible with H-E Parts variety of lifting devices, that ensure safety and efficiency are achieved in all service functions. This reputation carries on to H-E Parts flagship

Cone Crusher Liners Symons 3FT 4FT 4.25FT GTEK

4830-0023 Bowl Liner 4FT SHD. New GTEK MINING™ part suitable for Symons Cone Crusher. Manufactured by GTEK™. OEM® Part Number 4830-0023. Suits model Symons 4FT SHD. Mn18Cr2 / XT710. Net Weight 661kg. GTEK™ crusher parts are manufactured and warranted by GTEK™. 4830-0023 Bowl Liner 4.25FT STD.

Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher

Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher Spare Parts, Find Details and Price about Cone Crusher Wear Parts Cone Crusher Parts from Manganese Mantle Bowl Liner for Symons 7FT Cone Crusher Spare Parts Grand Heavy Machinery Co., Ltd Home Product Directory ManufacturingProcessing Machinery Mining Machinery

What is CS420 CS660 CS820 Cone Crusher Parts Bowl Liner and

What is CS420 CS660 CS820 Cone Crusher Parts Bowl Liner and Mantle, Metso Cone Crusher Parts Process manufacturerssuppliers on Video Channel of Made-in-China.

Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner

Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner Casting for Stone Cone Crusher Replacement Wear Parts,Cone Crusher Wear Parts, Cone Crusher Parts についての詳細を検索 Mining Machine Spares Tc845 3710 Mantle Concave Bowl Liner Casting for Stone Cone Crusher Replacement Wear Parts Grand Heavy Machinery Co., Ltd より

Compression mining crushers Primary crushers

Compression mining crushers solutions for breaking down hard minerals and ores. Enjoy optimum performance and reduced cost with compression crusher equipment and products. For over a century, has been renowned as the preferred crushing technology provider for mining and related industries.

All crusher types for your reduction needs Metso Outotec

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

® HP Series™ cone crushers Metso Outotec

® HP™ crushers are engineered to ensure maximum operator safety and easy maintenance. The crushers have an access from the top of the crusher to the principal components, an easy access for liner maintenance, and mechanical rotation of the bowl for removal with a simple press of a button. Maintenance tools are also available.