High Effect Classifiion Vibration Screen

Vibratory Screens General Kinematics

FINGER-SCREEN™ VIBRATING GRIZZLY SCREEN AGGREGATE SCREENS Bulk Processing Screens Find the perfect screen for your

Simulation of particles motion on a double vibrating flip-flow

2023年3月8日The surfaces of vibrating flip-flow screens have the advantages of high vibration intensity, non-blocking holes, easy depolymerization of clustered particles, and

Classification Vibrating Screen-Linear Motion GN Separation

Classification Vibrating Screen-Linear Motion Technical CharacteristicsAdvantages The wallboard is not welded. The steel plate with better impact toughness and cold

A review of process models for wet fine classification with high

2021年12月1日Screening technology has developed to be able to classify coarse to very fine particles using screen openings as small as 45 μm, with rate limitation according to the size classification. Nevertheless, modeling of the screening process has not developed at the same pace.

Process enhancement of vibrating classifier for tailings classification

2022年3月1日Moreover, when the elastic potential energy of the screen surface was released, it showed an opposite effect on the screen body and reduced the amplitude of the vibration of the screen body. These events improved the stability of the equipment. Download : Download high-res image (440KB) Download : Download full-size image;

Vibratory Screens General Kinematics

FINGER-SCREEN™ VIBRATING GRIZZLY SCREEN AGGREGATE SCREENS Bulk Processing Screens Find the perfect screen for your bulk processing system. STM-SCREEN™ EXTRA LARGE VIBRATING

Dry Vibrating Screens for mining and industrial

A Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification, sizing, scalping and recycling. Designed for your specific operation, our Dry Vibrating Screens come in a wide range of sizes ranging from 0.9m to 4.8m wide and up to 11.0m long.

Classification Vibrating Screen-Linear Motion GN Separation

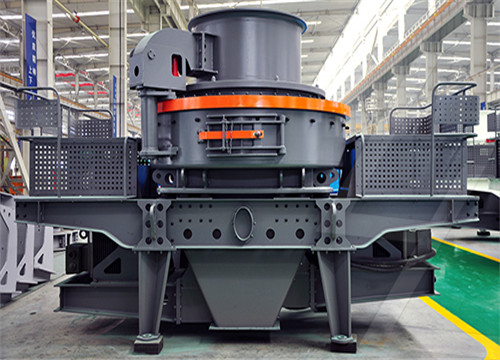

Parameter. GN Classification Vibrating Screen is widely used in the classification and screening of iron ore, coal, non-ferrous metal ore, building materials, chemical industry and other materials. The equipment adopts advanced design means such as finite element analysis and anti-fatigue analysis to ensure the reasonable structure, low energy

High Frequency Vibrating Screen GN Separation

GN High Frequency Vibrating Screen is mainly suitable for wet screening, classification and dewatering treatment of fine-grained materials in Mineral and coal preparation and other industry. High Frequency Vibrating

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

Vibrating Screen Working Principle Mineral

2015年7月26日The main cause of mechanical failure in screen decks is vibration. Even the frame, body, and bearings are affected by this. The larger the screen the bigger the effect. The vibration will crystallize the

High Effect Classification Vibration Screen mega-screening

High Effect Classification Vibration Screen. In plastic pellets production process, the plastic pellet screener in one important equipment that affect the plastic quality. The plastic pellet include many kind pellets, such normal plastic

What is the difference between vibrating screens and dewatering screens?

2023年3月10日4. Different forms of sieve surface. The vibrating screen is a horizontal or downward sieve surface to facilitate discharge. The screen surface of the dehydration screen is mostly upward climbing

Separation Equipment : Classification Vibrating Screen

GN Classification Vibrating Screen is anti corrode and anti wear so it can be used in various working conditions. Screen size can also be customized, and they are all with large processing capacity, high efficiency and stable performance. GN classification vibrating screen is fixed with two vibrators, the screen body moves in a linear direction

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

High-Speed Vibrating Screens Material Handling Equipment

Overstrom High-Speed Vibrating Screens High-Speed Vibrating Screens come in a variety of models, sizes, configurations and accessories for wet and dry screening. Screens may be inclined or horizontal, open or enclosed, customized from a variety of screen media and accessories.

Why a Vibrating Screen? MEKA

Screens materials thanks to effect of mechanical vibration. The body of the screen is vibrated by a vibration mechanism, causing the whole screen to shake. The material that needs to be sorted is classified on an equal basis under the effect of vibrating forces while passing over a sieve media.

Process enhancement of vibrating classifier for tailings classification

2022年3月1日The laboratory vibrating classifier was designed with dimensions of 0.12 m × 0.60 m (length × width). The elastic screen surface was inclined 4° and was made up of high elastic polyurethane with an aperture size of 0.125 mm × 0.50 mm (length × width).

Full range of BRU Vibrating Screens

BRU Vibrating Screens setting the standard for vibrating screens. Separating raw materials is a difficult process, but finding the right feed separation solution should not have to be. The big advantage is decreased maintenance and increased productivity that comes from a reliable vibrating screen option.

Separation Equipment : Classification Vibrating Screen

GN Classification Vibrating Screen is anti corrode and anti wear so it can be used in various working conditions. Screen size can also be customized, and they are all with large processing capacity, high efficiency and stable performance. GN classification vibrating screen is fixed with two vibrators, the screen body moves in a linear direction

Classification Vibrating Screen-Linear Motion GN Separation

Classification Vibrating Screen-Linear Motion Technical CharacteristicsAdvantages The wallboard is not welded. The steel plate with better impact toughness and cold bending is selected, and the imported HUCK rivet is used for hydraulic tension assembly.

High Frequency Vibrating Screen GN Separation

GN High Frequency Vibrating Screen is mainly suitable for wet screening, classification and dewatering treatment of fine-grained materials in Mineral and coal preparation and other industry. High Frequency Vibrating

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

What is the difference between vibrating screens and dewatering screens?

2023年3月10日4. Different forms of sieve surface. The vibrating screen is a horizontal or downward sieve surface to facilitate discharge. The screen surface of the dehydration screen is mostly upward climbing

High Effect Classification Vibration Screen mega-screening

High Effect Classification Vibration Screen. In plastic pellets production process, the plastic pellet screener in one important equipment that affect the plastic quality. The plastic pellet include many kind pellets, such normal plastic

Classification and Scope of Application of Vibrating Screen

2020年11月13日05 Single Shaft Vibrating Screen. The single shaft vibrating screen has a circular movement track, which has the advantages of simple structure, convenient maintenance, stable operation, reliable work, high efficiency, and good screen penetration. It is suitable for the classification of medium and fine materials.

Why a Vibrating Screen? MEKA

Screens materials thanks to effect of mechanical vibration. The body of the screen is vibrated by a vibration mechanism, causing the whole screen to shake. The material that needs to be sorted is classified on an equal

Basic concepts of vibrating screens: What they are, what they

Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size, starting from a bulk product in a continuous process. The inlet material (the raw product) advances from the part where the

High Frequency Dry Vibrating Screen kminda

Through the electromagnetic vibrator on both sides of the screen box high-frequency beating screen and the combined vibration of two high-frequency motors to achieve the effect of stratification and grading. Application. The dry screening is for fine classification(-10mm) of coal, brick making, chemical industry, fertilizer etc.

Classification of household micro using a multi-model

2 之The main Raman shifts of PET are 633,857, 1096, 1289, 1615, 1727, 2970, 3093 cm −1.These bands have been assigned to CCC in plane bending, a ring CC and C(O)–O stretching (857 cm −1), a ring mode (1096 cm −1), the anti, symmetric stretching vibration of C–O–C (1615 cm −1), and the C O and C(O)–O bonds (1289 and 1727 cm −1).The