Crushing Of Coal In Low Temperatures

Towards understanding of internal mechanism of coal reactivity

Heat release and accumulation in low-temperature oxidation of coal is the fundamental reason responsible for coal spontaneous combustion [8]. Coal with a spontaneous

Sources of underground CO: Crushing and ambient

2015年11月1日The spontaneous combustion of coal is complex, particularly the oxidation process that occurs at low temperature. It is well known that coal spontaneous

Study on the Influence of the Mechanical Crushing

2022年11月8日In the process of mechanical crushing, the coal sample not only changes in physical structure but also changes in chemical structure. With the decrease in particle

Characteristics of mass, heat and gaseous products

2017年10月5日First of all, run-of-mine coal was crushed to maximum size of 10 mm in the air. Then, the coal particles were pulverized to less than 0.098 mm by a secondary

Study on the Influence of the Mechanical Crushing Process on Low

@article{Hao2022StudyOT, title={Study on the Influence of the Mechanical Crushing Process on Low-Temperature Oxidation Characteristics of Coal Samples},

Research on Particle Size and Energy Consumption Law of Hard

To study the particle size distribution and energy variation law of hard coal under a load, an impact compression test of hard coal specimens under different impact loading

Spontaneous Combustion of Coal Practical

properties of the coal, its temperature increases. As the temperature increases, the oxidation reaction rate increases (typically doubling for each 10°C). Eventually the

1.1 Bituminous And Subbituminous Coal Combustion

1.1 Bituminous And Subbituminous Coal Combustion 1.1.1 General In wet bottom furnaces, coals with low fusion temperatures are used, resulting in molten ash or slag.

Reaction site evolution during low-temperature oxidation

2022年11月1日Coal oxidation at low temperatures is the heat source liable for the self-heating and spontaneous combustion of coal. This phenomenon has imposed severe

Study on the Influence of the Mechanical Crushing Process on Low

2022年11月8日In the process of mechanical crushing, the coal sample not only changes in physical structure but also changes in chemical structure. With the decrease in particle size of coal samples, more CO and CO 2 are produced in the process of low-temperature oxidation of coal, and the time to reach the cross-point temperature is advanced.

Study on the Influence of the Mechanical Crushing Process on Low

@article{Hao2022StudyOT, title={Study on the Influence of the Mechanical Crushing Process on Low-Temperature Oxidation Characteristics of Coal Samples}, author={Wanshu Hao and Shujie Yuan and Jinhu Li and Xiaoxue Xu and Jingjuan Geng}, journal={Combustion Science and Technology}, year={2022} } Wanshu Hao, Shujie

Study on the Influence of the Mechanical Crushing Process on Low

2022年11月8日In the process of mechanical crushing, the coal sample not only changes in physical structure but also changes in chemical structure. With the decrease in particle size of coal samples, more...

Study on the Change of Dielectric Properties and Chemical

coal were prepared under low-temperature oxidation condition, and the coal dielectric properties were measured with an impedance analyzer at frequencies ranging between 20 Hz and 30 MHz. The oxygen-

Modification mechanism of caking and coking properties

2019年4月11日The coal blends (4 kg) were charged into the coking chamber and then heated at a heating rate of ~ 6 °C/min up to 400 °C, followed by 3 °C/min up to 950 °C with a holding period of 30 min in an inert atmosphere. The cokes produced were then rapidly quenched to room temperature. Fig. 2

Free radical reaction characteristics of coal low-temperature

The free radical reactions can explain the chemical process of coal at low-temperature oxidation. Electron spin resonance (ESR) spectroscopy was used to measure the change rules of the different sorts and different granularity of coal directly; ESR spectroscopy chart of free radicals following the changes of temperatures was compared by the

Reaction site evolution during low-temperature oxidation of low-rank coal

2022年11月1日Coal oxidation at low temperatures is the heat source liable for the self-heating and spontaneous combustion of coal. This phenomenon has imposed severe problems in coal related industries.

What are the types of coal? U.S. Geological Survey

There are four major types (or “ranks”) of coal. Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbon-rich, and harder

Effect of relative humidity on the desulfurization performance of

1 At the center of the crushing cavity, due to the influence of the negative pressure shock wave airflow, the pressure rises again and then decreases rapidly at the center collision position. From Fig. 7 c, after the W wave, the temperature rises slowly, and the temperature at the center is the same as the inlet temperature. This is because after

Thermal Properties and Key Groups Evolution of Low-Temperature

2021年6月2日To deeply explore the spontaneous combustion disaster of coal caused by air leakage and oxygen supply, low-temperature coal oxidation experiments under different oxygen concentrations (DOC) were carried out. Within the coal spontaneous combustion characteristic measurement system, a synchronous thermal analyzer (STA) and a

Minerals Free Full-Text Particle-Crushing Characteristics and

2018年6月7日In solid backfilling coal mining (SBCM), the crushed gangue backfilling material (CGBM) is generally compacted circularly by a compaction machine in order to reduce its compressibility. In this cyclic compaction process, the particles are crushed, which has a significant effect on the deformation resistance of CGBM. However, the

Experimental Study on the Physisorption Characteristics of O2 in Coal

2020年4月24日Jingyu Zhao et al. analysed the critical points of the low-temperature oxidation stage of coal, including the critical temperature (97.45 ± 7.15 °C) and crack temperature (149.28 ± 8.32 °C) 17

Sources of underground CO: Crushing and ambient temperature

Sources of underground CO: Crushing and ambient temperature oxidation of coal @article{Tang2015SourcesOU, title={Sources of underground CO: Crushing and ambient temperature oxidation of coal}, author={Yibo Tang}, journal={Journal of Loss Prevention in The Process Industries}, year={2015}, volume={38}, pages={50-57} } Yibo Tang

Dynamic behaviours on oxidation heat release of key active

2022年7月15日Therefore, during the low-temperature oxidation, the changes in the microscopic properties of the coal were accompanied by the changes in the macroscopic heat. Increasing temperature, the oxidation process will produce CO, CO 2, H 2, C 2 H 2, CH 4, C 2 H 6 and other gases, which cause great harm to the environment [25], [26].

Study on the Influence of the Mechanical Crushing Process on Low

2022年11月8日In the process of mechanical crushing, the coal sample not only changes in physical structure but also changes in chemical structure. With the decrease in particle size of coal samples, more CO and CO 2 are produced in the process of low-temperature oxidation of coal, and the time to reach the cross-point temperature is advanced.

Study on the Influence of the Mechanical Crushing Process on Low

@article{Hao2022StudyOT, title={Study on the Influence of the Mechanical Crushing Process on Low-Temperature Oxidation Characteristics of Coal Samples}, author={Wanshu Hao and Shujie Yuan and Jinhu Li and Xiaoxue Xu and Jingjuan Geng}, journal={Combustion Science and Technology}, year={2022} } Wanshu Hao, Shujie

Study on the Influence of the Mechanical Crushing Process on Low

2022年11月8日In the process of mechanical crushing, the coal sample not only changes in physical structure but also changes in chemical structure. With the decrease in particle size of coal samples, more...

Thermal Properties and Key Groups Evolution of Low-Temperature

2021年6月2日To deeply explore the spontaneous combustion disaster of coal caused by air leakage and oxygen supply, low-temperature coal oxidation experiments under different oxygen concentrations (DOC) were carried out. Within the coal spontaneous combustion characteristic measurement system, a synchronous thermal analyzer (STA) and a

Study on the Change of Dielectric Properties and Chemical

coal were prepared under low-temperature oxidation condition, and the coal dielectric properties were measured with an impedance analyzer at frequencies ranging between 20 Hz and 30 MHz. The oxygen-

Modification mechanism of caking and coking properties

2019年4月11日The coal blends (4 kg) were charged into the coking chamber and then heated at a heating rate of ~ 6 °C/min up to 400 °C, followed by 3 °C/min up to 950 °C with a holding period of 30 min in an inert atmosphere. The cokes produced were then rapidly quenched to room temperature. Fig. 2

Reaction site evolution during low-temperature oxidation of low-rank coal

2022年11月1日In summary, it can be considered that the main active sites for coal oxidation at low temperature are hydroxyl and methylene groups. At higher temperatures, the hydroxyl group will be...

What are the types of coal? U.S. Geological Survey

There are four major types (or “ranks”) of coal. Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbon-rich, and harder

Effect of relative humidity on the desulfurization performance of

1 At the center of the crushing cavity, due to the influence of the negative pressure shock wave airflow, the pressure rises again and then decreases rapidly at the center collision position. From Fig. 7 c, after the W wave, the temperature rises slowly, and the temperature at the center is the same as the inlet temperature. This is because after

Experimental Study on the Physisorption

2020年4月24日Jingyu Zhao et al. analysed the critical points of the low-temperature oxidation stage of coal, including the critical temperature (97.45 ± 7.15 °C) and crack temperature (149.28 ± 8.32 °C) 17

Minerals Free Full-Text Particle-Crushing Characteristics and

2018年6月7日In solid backfilling coal mining (SBCM), the crushed gangue backfilling material (CGBM) is generally compacted circularly by a compaction machine in order to reduce its compressibility. In this cyclic compaction process, the particles are crushed, which has a significant effect on the deformation resistance of CGBM. However, the

Free radical reaction characteristics of coal low-temperature

Free radical reaction characteristics of coal low-temperature oxidation and its inhibition method Free radical reaction characteristics of coal low-temperature oxidation and its inhibition method Environ Sci Pollut Res Int. 2016 Dec;23 (23):23593-23605. doi: 10.1007/s11356-016-7589-x. Epub 2016 Sep 10. Authors

Dynamic behaviours on oxidation heat release of key active

2022年7月15日Therefore, during the low-temperature oxidation, the changes in the microscopic properties of the coal were accompanied by the changes in the macroscopic heat. Increasing temperature, the oxidation process will produce CO, CO 2, H 2, C 2 H 2, CH 4, C 2 H 6 and other gases, which cause great harm to the environment [25], [26].

Urea and CaCl2 as inhibitors of coal low-temperature oxidation

2012年6月5日Typical development of the coal sample weight during its oxidation in the temperature range 30–300 °C is illustrated in Fig. 1. Decrease in weight can be seen at the beginning of heating (up to about 120 °C) followed by increase in weight at temperatures 120–250 °C. The coal weight decrease can be explained mainly by moisture loss.

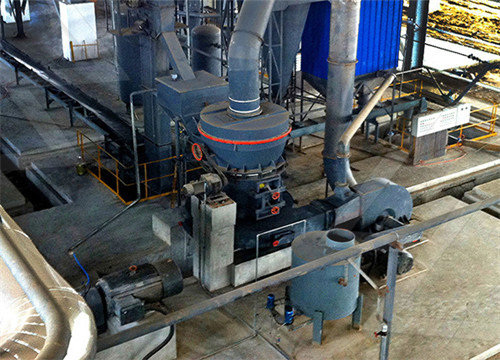

- Soya Magnetite Crushing Preparation Plant Sa

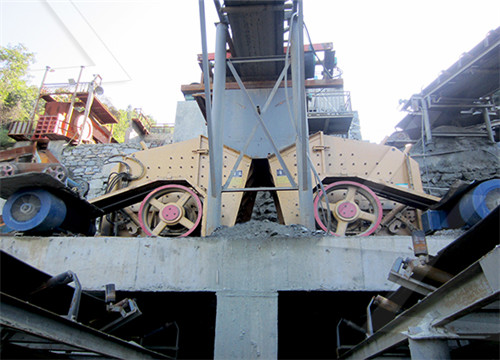

- 浙江绍兴浮石鄂式破碎设备

- 鄂破两个轮子哪个是皮带轮

- 郑州高低压壳体厂

- The Main Motion And Feed Motion Crusher Machine

- 型高效双机

- 53B砂机的价格ht-6012

- Dolomite Powder Crushing Equipment

- 湖南石灰石加工设备万吨

- 磨粉机村料筒中的枝状阀的作用

- Harga Mesin Stone Mining Mill Sanbo

- 比赛罗斯矿用设备

- 潍坊永固磨粉机价格青石设备

- 石场磨粉机图片

- Price Of Dieasal Mini Stone Mining Mill India