Center Drive Ball Mill Vs Side Driven Ball Mill

High Energy Ball Milling Union Process

根据热度为您推荐•反馈

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill

根据热度为您推荐•反馈

Ball Mills Mineral ProcessingMetallurgy

Overflow VS Grate Discharge Ball or Mill Why Retrofit

2015年6月24日The cost of a ball mill conversion from overflow to grate discharge is ‘fairly’ affordable at $65,000 for a 13′ x 15′ mill. This is only

Cement mill Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by

Planetary Ball Mills 101 Union Process

Planetary Ball Mills 101 Planetary ball mills share the same design as other basic ball mills a grinding jar filled with media and rotated on its own axis. But their unique

Mechanochemistry: Twin Screw Extrusion vs. continuosly

Mechanochemistry and ball milling (batch) is state of the art and described in literature. However for industrial scale, less information on continuously driven ball mills are

Why use a double-drive in a ball mill?

2023年2月27日A ball mill is a type of grinding mill used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics, and

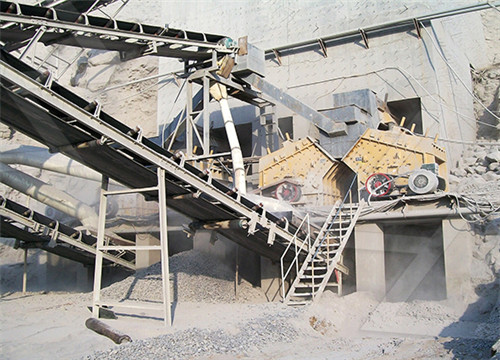

Difference and Choice of 2 Common Mills, Ball Mill and

2019年10月26日As the key milling equipment, there are considerable differences between grinding mill and ball mill from the outside and inside. Method of Operation From the view of method of operation, grinding mill

High Energy Ball Milling Union Process

The Attritor’s design accounts for much of the difference: conventional ball mills turn the entire drum or tank containing the media and the material, while Attritors stir the media in a stationary tank with a shaft and attached

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

Cement mill Wikipedia

Ball Mill Layout A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill

Planetary Ball Mills 101 Union Process

Planetary Ball Mills 101. Planetary ball mills share the same design as other basic ball mills a grinding jar filled with media and rotated on its own axis. But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size. These forces come into play as the grinding

Ball Mill Explained saVRee

A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be primary or secondary

SAG Mill Grinding Circuit Design Mineral

2016年6月6日SAG Mill vs Ball Mill. Design Drive Power. C. Total Feed Conditions, including total mill volumetric flow rate; 3650 mm semi-autogenous mill driven by a 3954 kW variable speed dc motor, and one

Ball Mills Best of 2023 911Metallurgist

Ball Mills Best 2023 Models. Showing all 16 results. Laboratory Ball Mill (Ball or Rod) Benchtop Ball Mill. US $ 12,000. Planetary Ball Mill. US $ 9,000. Floor Mounted Laboratory Grinding Mill. US $ 11,000. Small

What Are the Differences between Ball Mill and Rod

2023年2月15日Ball mills use steel balls with a diameter of less than 100mm as the grinding media, and the medium filling rate is 40% to 50%. Steel balls are mainly made of several materials: 1 High manganese

Ball Mill Drives Philadelphia Gear

These large coal crushing drive systems are usually rotated by motor-driven gearing. A typical application consists of a motor-driven primary single-stage reducer that, through a flexible coupling, drives a large open

Basic End Mills Technical Information MSC Industrial Supply Co.

Corner radius end mills have a rounded cutting edge and are used where a specific radius size is required. Corner chamfer end mills have an angled cutting edge and are used where a specific radius size is not required. Both types

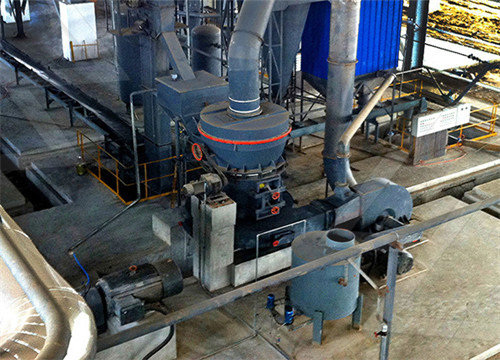

Super Orion S.O. Hosokawa Alpine

The drive sets the milling drum into slow rotation and the bed of milling media is thus activated, i.e. the balls are lifted and then impact back against the bed. Ball mills are usually operated below the critical speed. The

Stamp mill Wikipedia

A stamp mill consists of a set of heavy steel (iron-shod in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating

Stirred Mill an overview ScienceDirect Topics

The stirred mills are charged with a media size of 10–12 mm and operated at a maximum tip speed of 3–8 m/s. slowly such that the ball charge and slurry are not fluidized, but settle under gravity. The screw action pulls the ball charge up the center of the mill, and the charge eventually cascades over the edge of the screw, creating a

Ball mill liner Wear Parts For Industry Qiming Casting

As a wear-resistant foundry, Qiming Casting manufactures manganese steel, Cr-Mo alloy steel, and Ni-hard steel liners for all kinds of ball mills, which include: single wave liners, modified single wave liners, double wave liners, shell liners, feed head liners, and discharge end liners. Qiming Casting is Your Foundry for Ball Mill Liners!

AMIT 135: Lesson 7 Ball MillsCircuits Mining

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill

Cement mill Wikipedia

Ball Mill Layout A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill

Conventional Ball Mill vs. Attritors Union Process

The Attritor’s design accounts for much of the difference: conventional ball mills turn the entire drum or tank containing the media and the material, while Attritors stir the media in a stationary tank with a shaft and attached arms or discs resulting in a more efficient use of energy for the milling process.

Planetary Ball Mills 101 Union Process

Planetary Ball Mills 101 Planetary ball mills share the same design as other basic ball mills a grinding jar filled with media and rotated on its own axis. But their unique design takes advantage of centrifugal force and the Coriolis effect to grind materials to a very fine or even micron size.

SAG Mill Grinding Circuit Design Mineral

2016年6月6日SAG Mill vs Ball Mill. Design Drive Power. C. Total Feed Conditions, including total mill volumetric flow rate; 3650 mm semi-autogenous mill driven by a 3954 kW variable speed dc motor, and one

Ball Mills Best of 2023 911Metallurgist

Ball Mills Best 2023 Models. Showing all 16 results. Laboratory Ball Mill (Ball or Rod) Benchtop Ball Mill. US $ 12,000. Planetary Ball Mill. US $ 9,000. Floor Mounted Laboratory Grinding Mill. US $ 11,000. Small

Overflow Type Ball Mill VS Grid Type Ball Mill Mining-pedia

2022年6月30日The ball mill is 10%-25% higher, suitable for one-stage rough grinding or the first stage of two-stage grinding, and can also be used to grind easily crushed and soft ores. When the particle size of the material needs to be ground to a uniform product of 48-65 meshes, it is better to use a grid-type ball mill. Overflow Type Ball Mill.

Ball Mill Drives Philadelphia Gear

These large coal crushing drive systems are usually rotated by motor-driven gearing. A typical application consists of a motor-driven primary single-stage reducer that, through a flexible coupling, drives a large open

Stamp mill Wikipedia

Ball mill a horizontal cylinder containing metal balls to crush the material Hammermill a more modern device that also can crush material to fines. Hammer mill an historical forge using trip hammers Stamp sand the

Ball mill liner Wear Parts For Industry Qiming Casting

As a wear-resistant foundry, Qiming Casting manufactures manganese steel, Cr-Mo alloy steel, and Ni-hard steel liners for all kinds of ball mills, which include: single wave liners, modified single wave liners, double wave liners, shell liners, feed head liners, and discharge end liners. Qiming Casting is Your Foundry for Ball Mill Liners!

sbm center drive ball mill vs side driven ball mill.md main

Sign in / Register Toggle navigation Menu. S ; Project information Project information Activity

Stirred Mill an overview ScienceDirect Topics

The stirred mills are charged with a media size of 10–12 mm and operated at a maximum tip speed of 3–8 m/s. slowly such that the ball charge and slurry are not fluidized, but settle under gravity. The screw action pulls the ball charge up the center of the mill, and the charge eventually cascades over the edge of the screw, creating a

Ball Mills PSP Eng

Mills are driven by a circumferential drive with a gearbox DMG 2 with two integrated pinions via a girth gear or with a gearbox, countershaft and one pinion for mills with a smaller diameter. An auxiliary drive is used for turning of the mill drum during maintenance. Mill shell Mill seating Mill drive Range of two-chamber mills