Raw Materials Cement Production

How Cement Is Made

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl

Cement Extraction and processing Britannica

根据热度为您推荐•反馈

Full article: An overview of alternative raw materials used

2020年9月29日Cement production process with waste utilisation areas Display full size In stage one, the essential raw materials-limestone, laterite, bauxite, kaolinite, clay, iron

Cement Manufacturing Raw Materials Charah® Solutions

CEMENT MANUFACTURING RAW MATERIALS Charah Solutions is committed to providing our customers with a complete portfolio of high-quality raw materials and

Cement Production Process Cement Manufacturing Process

2020年8月25日Cement raw material preparation: Limestone is main raw materials for cement manufacturing, and most cement plants are located next to the quarry to

(PDF) Cement Manufacturing ResearchGate

2015年12月9日Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA) Conference Paper Dec 2021 Hüseyin Gökçekuş Nivin Ghaboun Dilber Uzun Ozsahin Berna Uzun

RAW MATERIALS IN CEMENT PRODUCTION

2019年2月7日The main materials used in cement production are minerals containing calcium oxide, silex, alumina and iron oxide. These components are rarely found in one type of raw material; therefore, for

Cement Manufacturing Process Phases Flow Chart

2012年8月30日Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone

Raw Materials of Cement Expert Civil

The ingredients of ordinary cement as mentioned above, perform the following functions: Lime (CaO) : This is the important ingredients of cement and its proportion is to be carefully maintained. The lime in excess

How Is Cement Produced in Cement Plants Cement

The raw materials needed for cement production mainly include limestone (main material, providing CaO), clay materials (providing SiO 2, Al 2 O 3 and a small amount

How Cement Is Made Heidelberg Materials

The most important raw materials for making cement are limestone, clay, and marl. These are extracted from quarries by blasting or by ripping using heavy machinery. Extracting raw material II: crushing and transportation Wheel loaders and dumper trucks transport the raw material to the crushing installations.

Cement Manufacturing Raw Materials Charah® Solutions

CEMENT MANUFACTURING RAW MATERIALS Charah Solutions is committed to providing our customers with a complete portfolio of high-quality raw materials and byproducts for cement and concrete manufacturing including alumina source materials and supplementary cementitious materials (SCMs).

Materials used to produce portland cement

The two principal materials from which portland cement is made are a material of high lime content, such as limestone, chalk, shells, or marl, and a material of high silica and alumina content such as clay, shale, or blast-furnace slag. A small amount of iron is also needed.

Environmental impact of cement production and Solutions: A

2022年1月1日The increasing harvesting of raw materials for mounting cement manufacturing causes reduction in quantity of the non-renewable resources such as limestone. The activities linked to harvesting of the resources from natural surroundings, damages the green landscape which is the habitat of flora and fauna exposing to the risk

Cement Wikipedia

World production is about four billion tonnes per year, [3] of which about half is made in China. [4] [5] If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world with up to 2.8

(PDF) Cement Manufacturing ResearchGate

2015年12月9日Evaluation of Cement Manufacturing Methods Using Multi Criteria Decision Analysis (MCDA) Conference Paper Dec 2021 Hüseyin Gökçekuş Nivin Ghaboun Dilber Uzun Ozsahin Berna Uzun

How Is Cement Produced in Cement Plants Cement Making

The raw materials needed for cement production mainly include limestone (main material, providing CaO), clay materials (providing SiO 2, Al 2 O 3 and a small amount of Fe 2 O 3 ), correction raw materials (to supplement some insufficient ingredients), and auxiliary raw materials (such as mineralizer, cosolvent, grinding aid), etc.

Characterization of raw materials and final product

2018年12月18日Cement is a hydraulic binder formed by the grinding process of cement clinker, as intermediate product, which is produced by baking the lime-clay raw material mixture to the sintering temperature

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日The raw material of cement usually include limestone, clay, shale, tripoli, and others, limestone is always the main composition, for reducing g the transportation cost, most cement plant would be located

RAW MATERIALS FOR CEMENT MANUFACTURING

Raw materials for the production of cement Minerals of natural origin as well as industrial products can be used for the production of cement. Starting material for this purpose are mineral compounds containing the

Cement Industry: QA of Raw Materials Process

2021年3月31日There are six very common applications in the cement industry. These are drying material samples, ashing, calcining, loss on ignition testing, testing burnability of cement, and testing free lime

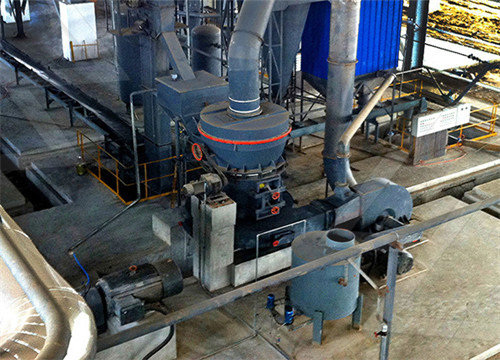

Cement Raw Material Loesche

The end customer is the Egyptian Cement for Cement Projects Management S.A.E. The planned new plant is located nearly 500 km south of Cairo in Sohag. The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output

2023 Canvas Frames Market Look Into Business Overview,

2023年2月27日11 Alternative Raw Materials for Cement Production Upstream, Opportunities, Challenges, Risks and Influences Factors Analysis. 11.1 Alternative Raw Materials for Cement Production Key Raw Materials.

Cement Industry Outlook 2022-2030 News and Statistics

2022年5月14日Cement production requires a number of raw materials, including limestone, clay, and gypsum. If these materials become scarce or more expensive, it could put pressure on cement prices and profitability. Finally, government regulations can also have an impact on the outlook for the cement industry.

Materials used to produce portland cement

The two principal materials from which portland cement is made are a material of high lime content, such as limestone, chalk, shells, or marl, and a material of high silica and alumina content such as clay, shale, or blast-furnace slag. A small amount of iron is also needed.

Environmental impact of cement production and Solutions: A

2022年1月1日The increasing harvesting of raw materials for mounting cement manufacturing causes reduction in quantity of the non-renewable resources such as limestone. The activities linked to harvesting of the resources from natural surroundings, damages the green landscape which is the habitat of flora and fauna exposing to the risk

Cement Industry: QA of Raw Materials Process

2021年3月31日Top global cement producers include LafargeHolcim with 108 plants and 386-million-ton capacity; followed by Anhui Conch, then China National Building Material. A number of national and international

Characterization of raw materials and final product

2018年12月18日Cement is a hydraulic binder formed by the grinding process of cement clinker, as intermediate product, which is produced by baking the lime-clay raw material mixture to the sintering temperature

Alternative raw materials Cement industry news from Global Cement

2023年2月10日Peru: Unacem Perú plans to 'significantly increase' its cement production capacity 'in the medium-term future.' Prior to that, the producer will invest US$130m in capital expenditure during 2023, double what it invested in 2022. The investments will go towards slightly expanding the producer's capacity from 8.3Mt/yr and increasing

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日The raw material of cement usually include limestone, clay, shale, tripoli, and others, limestone is always the main composition, for reducing g the transportation cost, most cement plant would be located

What are the raw materials for cement production? Studybuff

The most important raw materials for making cement are limestone, clay, and marl. These are extracted from quarries by blasting or by ripping using heavy machinery. What are two process of manufacturing of cement? Manufacturing Of Cement. by any one of the two methods : (i) Dry process, and (ii) Wet process. What is the annual production of cement?

Investigation of raw materials for cement industry of

2018年9月13日On an average the production of cement has been increased to 3498 tonnes from year 2003 until 2017 [1]. Cement sector in Pakistan is divided into two zones: North and South, Major players in...

Cement Raw Material Loesche

The end customer is the Egyptian Cement for Cement Projects Management S.A.E. The planned new plant is located nearly 500 km south of Cairo in Sohag. The LOESCHE scope of delivery includes a raw

2023 Canvas Frames Market Look Into Business Overview,

2023年2月27日11 Alternative Raw Materials for Cement Production Upstream, Opportunities, Challenges, Risks and Influences Factors Analysis. 11.1 Alternative Raw Materials for Cement Production Key Raw Materials.

Concrete Production an overview ScienceDirect Topics

Regarding the cycle of concrete production as a construction material—that is, from cradle-to-gate—(Table 15.5) 74% to 81% of the total CO 2 emission is attributed to the manufacturing of cement (Flower and Sanjayan, 2007). The second major impact is the GGBFS, and third one is coarse aggregate.

Sustainable Clinker and Cement Production by Using Alternative Fuels

Sustainable Clinker and Cement Production by Using Alternative Fuels and Raw Materials. Our expertise. According to the International Energy Agency, the high-temperature process used in the manufacturing of cement accounts for around eight percent of the world’s anthropogenic carbon dioxide emissions. The process also

(PDF) Assessment of raw materials for cement industry in Sohag

2013年1月1日ssessment of raw materials for cement industry in Sohag area 345 . silica modulus is ranging between 1.78% and 2.84%; low silica modulus can be increased . using corrective sands. The average

Minerals Free Full-Text Efficiency of Chemical and Biological

The recovery of metals and the valorisation of the leach residues in the construction sector will substantially minimize the mining of virgin raw materials, including ores and aggregates, as well as reduce the carbon footprint of metal production and improve the sustainability of the mining and cement industry.