Books On Types Of Aggregate Crusher Video

Understanding the Different Types of Crushers Agg-Net

根据热度为您推荐•反馈

All crusher types for your reduction needs Metso Outotec

根据热度为您推荐•反馈

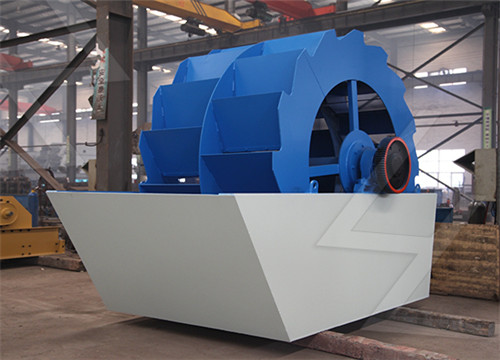

Aggregates McLanahan

McLanahan designs and manufactures equipment that can be used in all steps of the production of construction aggregates, from crushing the material to the desired size and sorting the various sizes for specific

Aggregates for Concrete

aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The material and its characteristics, e.g., its hardness, density, shape and condition, will affect the type of crusher that needs to be used. Knowing the material characteristics as well as the advantages

Crushed Stone Aggregates Heidelberg Materials

Crushed stone aggregates are produced by crushing quarried rock, then screening it to sizes appropriate for the intended use. Production of crushed stone has three stages: Primary crushing to break down the stone to a

What are the Different Types of Aggregate Crushers?

2021年12月14日An aggregate crusher is a machine designed to grind or pulverize various types of rock into small, relatively uniform pieces. Aggregate crushers are used

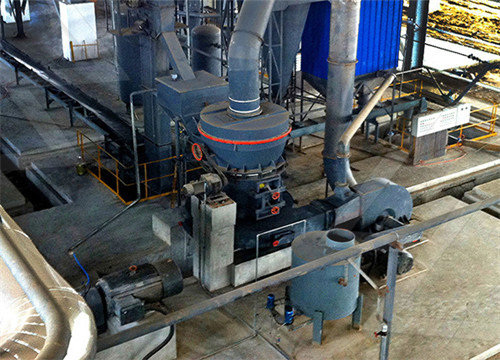

Aggregate Crusher Turn Stone Materials Into Building

First of all, pebbles and other aggregate materials enter the jaw crusher for sale for primary crushing; the finished materials are transported to the next processing flow by belt conveyors. PE750 1060 jaw crusher. Model: PE

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

P&Q University Lesson 7: CrushingSecondary Breaking

2019年9月2日In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread over these stages to better control the product size and quality, while minimizing waste. The primary stage was once viewed merely as a means to further reduce stone following the blast or excavation

Crushers an overview ScienceDirect Topics

In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2)

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Aggregate Crushers, for Rock, OreMinerals Gilson

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour

Crushed Stone Aggregates Heidelberg Materials

Crushed stone aggregates are produced by crushing quarried rock, then screening it to sizes appropriate for the intended use. Production of crushed stone has three stages: Primary crushing to break down the stone to a

What are the Different Types of Aggregate Crushers?

2021年12月14日An aggregate crusher is a machine designed to grind or pulverize various types of rock into small, relatively uniform pieces. Aggregate crushers are used in mining, quarrying and recycling operations. Several types of crushers can perform this task including jaw crushers, gyratory crushers, impact crusher and cone crushers,.

Aggregate Crusher Turn Stone Materials Into

In the aggregate processing line, we usually use the following aggregate crusher types, such as: jaw crusher, cone crusher, horizontal shaft impact crusher and so on. The crushing of aggregate is mainly divided into

books on types of aggregate crusher pdf github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Aggregate Crushers High-efficiency And Eco-friendly

APF1210 impact aggregate crusher Capacity: 100-160 (t/h) Model: APF1210 Rotor diameter (mm): Φ1200×1000 Feed opening size (mm): 450×1060 Max Feeding size (mm): 350 Processing capacity (t/h): 100-160 Mixing power (kw): 90-110 Total weight (t): 17 Dimension (L×W×H) (mm): 2550×1940×2110 Now

Investigation on the morphological and mineralogical properties of

2020年1月22日In this , the role of crushing operation on the cubical controlling features of coarse aggregates, and its influence on the shape distribution characteristics of aggregates (i.e. angularity,...

Crushed Stone Gitti Latest Price, Manufacturers

40 MM Crusher Aggregate ₹ 350/ Ton Get Latest Price Size: 40 MM Color: Gray Form: Solid Surface Finish: Rough Material: Stone Country of Origin: Made in India M/s. Parshaw Cement Company Kesarpura, Ambapura,

Impact Crusher an overview ScienceDirect Topics

There are many different types of crusher, such as jaw, gyratory, cone (or disc) and impact crushers (Figure 16.8 ), each of which has various advantages and disadvantages according to the properties of the material being crushed and the required shape of the aggregate particles produced. Sign in to download full-size image Fig. 16.8.

P&Q University Lesson 7: CrushingSecondary Breaking

2019年9月2日Virgin or natural stone processing uses a multi-stage crushing and screening process for producing defined aggregate sizes from large lumps of rock. Such classified final fractions are used as aggregates for concrete, asphalt base, binder and surface course layers in road construction, as well as in building construction.

Crushers an overview ScienceDirect Topics

In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2)

What Is Primary, Secondary, and Tertiary Crushing?

2021年1月10日The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

Aggregate Crushers, for Rock, OreMinerals Gilson

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour

Crushed Stone Aggregates Heidelberg Materials

Crushed stone aggregates are produced by crushing quarried rock, then screening it to sizes appropriate for the intended use. Production of crushed stone has three stages: Primary crushing to break down the stone to a

Design and Construction of Rock Crushing Machine from

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use. The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous use.

Aggregate Crushers High-efficiency And Eco-friendly

APF1210 impact aggregate crusher Capacity: 100-160 (t/h) Model: APF1210 Rotor diameter (mm): Φ1200×1000 Feed opening size (mm): 450×1060 Max Feeding size (mm): 350 Processing capacity (t/h): 100

Investigation on the morphological and mineralogical properties of

2020年1月22日In this , the role of crushing operation on the cubical controlling features of coarse aggregates, and its influence on the shape distribution characteristics of aggregates (i.e. angularity,...

Bucket crusher manufacturer crushing machine MB S.p.A.

MB Crusher is present all over the world. 8 Branch offices support the headquarters with promoting our products and assisting our customers in all 5 continents. With a dealer network of more than 230 locations we are able to distribute MB Crusher products to more than 150 countries.

sbm/sbm books on primary cone aggregate crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Concrete Crusher Turn Waste Aggregate Into Useful

Type: AIM1149JC98 Transportation length(mm): 13500 Transportation width(mm): 2700 Transportation height(mm): 4200 Weight(t): 57 Jaw crusher model: JC98 Max feed size(mm): 550 discharging mouth