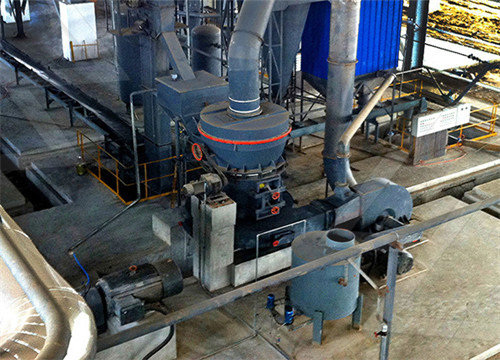

Coal Mill Pulverizer Rotating Table

Power Pulverizers

根据热度为您推荐•反馈

Coal Pulverizers an overview ScienceDirect Topics

In Appendix 6A we show a calculation taken from Musto (1978) for the primary and secondary air required for coal pulverizer with 4.5 metric ton per hour (10,000 lb/h) coal

进一步探索

What is a coal pulverizer? QuoraCoal Pulverizer Maintenance Improves Boiler Combustio根据热度为您推荐•反馈

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Oversized pulverized coal impacts with the rotating classifier and drops back onto the grinding table for further grinding. Correctly sized coal particles pass through the classifier and exit the mill through the

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification.

Pulverizers 101: Part I POWER Magazine

2011年8月1日Our experience with both RP and MPS pulverizers has been that mills designed for a throughput of about 120,000 pounds of coal per hour, an HGI of about 45 to 50, and coal fineness exceeding 75%

Mbf coal pulverizers foster wheeler SlideShare

2021年10月3日Dynamic Pressurized Rotating Classifier The rotating classifier offers coal flow and fineness control using variable speed drive. This new design will greatly improve (10% to 30% output) and increase

Coal Pulverizer Maintenance Improves Boiler Combustion

2015年12月1日We have found that targeting an A/F ratio around 1.8 lb of air per lb of fuel is best. For some pulverizer types, such as ball tube mills and high-speed attrition mills, often a 1.6 A/F ratio is

COAL PULVERIZER DESIGN UPGRADES TO MEET THE

The MPS mill is classified as an air-swept, pressurized, vertical spindle, table/roller mill. It contains an integral classifier, a grinding section, a windbox (plenum), and auxiliary

Advantages of Vertical Coal Mill linkedin

2023年3月8日Here are some of the key advantages of vertical coal mills: Higher efficiency: Vertical coal mills use a rotating table and rollers to crush and grind coal,

Boilers machinery : Coal Pulverizer Heavy Industries, Ltd.

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification.

Coal Pulverizer Maintenance Improves Boiler

2015年12月1日Install rotating throats (C) to ensure proper velocity, improve primary classification, and reduce coal rejects. Ensure optimum bullring and roll geometry (D) to achieve 1/4-inch roll-ring...

USA Roll-and-race pulverizer with rotating throat

In the so-called bowl mill roll-and-race pulverizer, the rolls are stationary and the ring rotates. The principal components of a bowl mill are a rotating bowl which is equipped with a...

Mbf coal pulverizers foster wheeler SlideShare

2021年10月3日Dynamic Pressurized Rotating Classifier The rotating classifier offers coal flow and fineness control using variable speed drive. This new design will greatly improve (10% to 30% output) and increase

Advantages of Vertical Coal Mill linkedin

2023年3月8日Here are some of the key advantages of vertical coal mills: Higher efficiency: Vertical coal mills use a rotating table and rollers to crush and grind coal, which provides a more uniform particle

Types of Boiler Coal Pulverizers Bright Hub Engineering

2010年1月29日There are basically three different types of pulverizing. 1. Attrition Type. Coal feeds onto a steel rotating table. Tapered, cylindrical, or spherical rollers on top of the table, under spring pressure, exert force on the coal particles on the table. When the table rotates, the coal passes between the rollers and the table and gets ground due

Wholesale coal pulverizer machine And Parts From Suppliers

Find coal pulverizer machine types and parts from wholesalers in China. Air Swept Coal Mill for Pulverized Coal Preparation Hammer Ball Mill Machines $6,999 and Cutter Grinders. Surface grinders are equipped with a rotary table and chuck. A chuck holds material in place while the wheel and object rotate to produce a smooth finish. For

Air-Swept Coal Mill Of High Quality Fote Machinery

3.2 The rotating part of the coal mill The main body of the coal mill is the rotating part, in which the raw coal pieces are dried and ground. The rotating part is composed of a hollow shaft, a cylinder, a lifting plate, a

Thermal Power Plant Part 2 PDF Mill (Grinding) Secondary

The balls are between a top stationary race or ring and a rotating bottom Ring, which is driven by the vertical shaft of the pulverizer. Ballrace mill • The coal is supplied through the rotating table feeder at The over sized particles are returned for further grinding in the mill. The coal air mixture from the classifier moves to the

MBF Mill Coal Pulverizers yumpu

2013年4月21日Coal Lower Airport Attached to the Rotating Table MBF Mill Coal Pulverizers Upper Airport- Sized to Match Fuel Requirements Maintenance Parts Stationary Wear Ring attached to Mill Housing ROTATING AIRPORT DESIGN Our latest improvement in MBF air-coal flow geometry reduces wear on the airport surfaces. The rotation of the

Dynamic Modelling and Simulation of Coal Pulverizer

of the pulverizer, pulverizer turn down ratio and capacity, maintaining minimum pulverizer outlet temperature, avoiding pulverizer in and out of service during megawatt load ramp up or down, non-availability of design range of coal with varying GCV, minimum volatile matter content in coal being fired etc.

USA Rotating throat for coal pulverizer Google

Crushing table crown for medium-speed mill USA (en) * 1982-12-08: 1986-08-12: Combustion Engineering, Inc. Vane wheel arrangement with nihard wear plates Integrated high pressure drop rotating throat for a coal pulverizer WOA1 (en) * 1999-04-21: 2000-11-02: Mitsui Babcock Energy Limited:

Used Pulverizers Mills for sale. Hosokawa equipmentmore

600-1,000 LBS/HR, 75HP Reduction Engineering Pulverizer. USED. Manufacturer: Reduction Engineering. 75HP Reduction Engineering Pulverizer Model 85XLP 75 HP Main Motor Rated For Approx. 600-1,000 LBS/HR Eriez Metal Separator 432MM (17") Mill Disks Includes Several Spare Disks Cyclone With Rotary Air-Lock Powere...

How To Maintain a Coal Pulverizer? (All You Need To Know)

According to the rotating speed of the grinding parts of the coal mill, the coal mill can be divided into a low-speed coal mill, a medium-speed coal mill, and a high-speed coal mill. The air-swept ball mill is a kind of low-speed coal mill.

Dynamic Modelling and Simulation of Coal Pulverizer

of the pulverizer, pulverizer turn down ratio and capacity, maintaining minimum pulverizer outlet temperature, avoiding pulverizer in and out of service during megawatt load ramp up or down, non-availability of design range of coal with varying GCV, minimum volatile matter content in coal being fired etc.

Plant engineering solutions for any mission Loesche

Plant engineering solutions for any mission Loesche

Advantages of Vertical Coal Mill linkedin

2023年3月8日Here are some of the key advantages of vertical coal mills: Higher efficiency: Vertical coal mills use a rotating table and rollers to crush and grind coal, which provides a more uniform particle

USA Rotating throat for coal pulverizer Google

Crushing table crown for medium-speed mill USA (en) * 1982-12-08: 1986-08-12: Combustion Engineering, Inc. Vane wheel arrangement with nihard wear plates Integrated high pressure drop rotating throat for a coal pulverizer WOA1 (en) * 1999-04-21: 2000-11-02: Mitsui Babcock Energy Limited:

Types of Boiler Coal Pulverizers Bright Hub Engineering

2010年1月29日There are basically three different types of pulverizing. 1. Attrition Type Coal feeds onto a steel rotating table. Tapered, cylindrical, or spherical rollers on top of the table, under spring pressure, exert force on the coal particles on the table.

Wholesale coal pulverizer machine And Parts From Suppliers

Find coal pulverizer machine types and parts from wholesalers in China. Air Swept Coal Mill for Pulverized Coal Preparation Hammer Ball Mill Machines $6,999 and Cutter Grinders. Surface grinders are equipped with a rotary table and chuck. A chuck holds material in place while the wheel and object rotate to produce a smooth finish. For

MBF Mill Coal Pulverizers yumpu

2013年4月21日Coal Lower Airport Attached to the Rotating Table MBF Mill Coal Pulverizers Upper Airport- Sized to Match Fuel Requirements Maintenance Parts Stationary Wear Ring attached to Mill Housing ROTATING AIRPORT DESIGN Our latest improvement in MBF air-coal flow geometry reduces wear on the airport surfaces. The rotation of the

Air-Swept Coal Mill Of High Quality Fote Machinery

3.2 The rotating part of the coal mill The main body of the coal mill is the rotating part, in which the raw coal pieces are dried and ground. The rotating part is composed of a hollow shaft, a cylinder, a lifting plate, a

Used Pulverizers Mills for sale. Hosokawa equipmentmore

600-1,000 LBS/HR, 75HP Reduction Engineering Pulverizer. USED. Manufacturer: Reduction Engineering. 75HP Reduction Engineering Pulverizer Model 85XLP 75 HP Main Motor Rated For Approx. 600-1,000 LBS/HR Eriez Metal Separator 432MM (17") Mill Disks Includes Several Spare Disks Cyclone With Rotary Air-Lock Powere...

Thermal Power Plant Part 2 PDF Mill (Grinding) Secondary

The balls are between a top stationary race or ring and a rotating bottom Ring, which is driven by the vertical shaft of the pulverizer. Ballrace mill • The coal is supplied through the rotating table feeder at The over sized particles are returned for further grinding in the mill. The coal air mixture from the classifier moves to the

Reliable Coal Pulverizers and Mills ? BabcockWilcox

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Pulverizers for Laboratory Gilson Co. GlobalGilson

Holmes Coal Pulverizers are available in three benchtop models to reduce coal and coke from No. 4 to No. 60 sieve size. Available with manual feed or 1/8hp chain-driven auger feed, the Holmes Pulverizers have a processing rate of 0.9lb/min (400g/min) to 1lb/min (450g/min) from 0.5L feed hoppers.

KRB1 Hydraulic cylinder for coal pulverizer Google

2011年1月25日As shown in Figure 1, the coal mill according to the prior art is a centrifugal force generated in conjunction with the rotation of the rotary table 2, the rotary table 2, the coal...

Classifier cage for rotating mill pulverizers Sure Alloy Steel

1996年1月29日Coal pulverizers are extensively used in the power-generating industry to process coal into finely ground "fines" suitable for combustion. A common type of pulverizer is the bowl mill pulverizer, in which a bowl- or ring-shaped grinding plate is rotated while heavy grinding wheels crush and grind coal fed onto the plate from a feedpipe.