Dry Aggregate Screeding Equipment Choosing The Right Screed

How to Maximize Your Aggregate Screening Equipment

2021年5月10日 Screening efficiency measures how much of the desired aggregate is accurately separated during the screening of aggregate. For example, if your screens are operating at 80% efficiency, that means 80% of the desired aggregate size passes

Choosing the Right Screed CSC Screeding

2015年5月19日 Traditional floor screeds. Traditional screeds basically consist of cement and sand, at a ratio of 1:3, 1:4, or 1:5. The cement and

Choosing the Right Screed| Concrete

2011年12月5日 Screed bars are easy to attach, remove, and replace, and they come in lengths up to 16 feet. In practice, though, screeds longer

A Guide to Mechanical Screening Aggregates Equipment,

2015年6月11日 Do so at your own detriment. To learn more about mechanical screening processes and equipment, contact AEI with specific questions about your processes or

Selecting the Best Tool for Properly Screeding Concrete

2019年9月23日 Screeding takes those anomalies out of the finished surface, giving you a smooth, level surface to cure. The Best Tool for Screeding Concrete. Technically, the

Method Statement of Screeding on Slab qaqcconstruction

2022年5月11日 Ready-mix Screed (Before screeding, the ready mix plant and mix design must be approved.) On-site mix Screed (The following mix ratio should be used for the

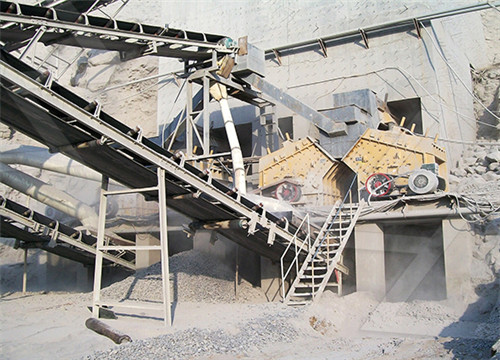

How to Choose the Right Screening Equipment

Screening equipment performs essential functions for a variety of aggregate processing applications. In order to ensure this important task is completed properly, you’ll need to

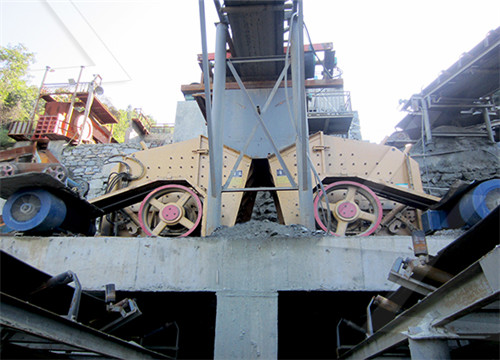

Crushing and Screening Equipment Guide Tricon Mining

Our goal is to provide a piece of equipment that helps you increase profitability by providing a solution to your crushing and screening challenges. For all your Bulk Material Handling,

dry aggregate screeding equipment the101guitarbar

Dry Aggregate Screeding Equipment Choosing The Right Screed. Semi Dry Screed vs Flowing Screed. Which is Best Semi Dry Screed. The Semi Dry Screed is the traditional

dry aggregate screeding equipment

17 Oct 2016 Important steps to make sure to follow when screeding as pouring an ordinary cement mixed with aggregates and water to a floor base Ask about the equipment they

Aggregate grades and quality parameters CSC

2014年4月28日 The European Standards (EN13139) and the British Standards (BS8204) provide specific guidelines regarding the choice of aggregates for specific screeding purposes. Right from grading to the

Screed The Components Needed The Screed Scientist®

From the type of cement, to the grade of aggregate and the method of storage of screed material there are several details that determine the final quality of a screed. Though mix proportions vary for depending on the intended use of the screed, the normal range specified for cement-sand levelling screeds is a mix proportion of 1:4.5

Choosing the Right Screed CSC Screeding

2015年5月19日 Traditional floor screeds. Traditional screeds basically consist of cement and sand, at a ratio of 1:3, 1:4, or 1:5. The cement and sand are combined with potable water to obtain a workable mixture.

Floor screeding with lightweight concretes and

The Latermix Cem range of concretes can be used for base screeds that are strong and very lightweight (450 600 kg/m 3) and contribute significantly to the thermal insulation of the slab. Latermix Cem Classic and Maxi are no

Basics of Screeding For Concrete and Masonry

2022年5月3日 In addition, screeding tools can be hard to handle. Screeding a 3-foot-wide walkway is manageable by one person. But when the screeding tool is a full-length two-by-four (8 feet or even longer), it is

Concrete vs Floor Screeds: What is The

2018年5月4日 Concrete has a much coarser mixture than screed, consisting of larger, hard-core aggregates, which are the key element that gives it its durability and makes it strong and long lasting. Applying a

What Is Concrete Screed Concrete Screed Specifications

2023年2月14日 Concrete Screed Curing and Dimension. Crack Free Screed. Clean. Dry. Flatness. Composition of Concrete Screed. A floor screed is usually a cementitious material made from a 1:3 or 1:4.5 ratio of cement to sharp sand. It may be applied onto either a solid in-situ concrete ground floor slab or onto a precast concrete floor unit.

Concrete Screed AdvantagesApplication DAILY CIVIL

2023年3月7日 4. Once it is evenly spread and the required thickness is achieved, the screed surface is given a finish. Generally, a smooth surface finish is given to the surface of the concrete screed. But it also depends on the intended use. 5. The layer of concrete screed is left to dry for some time, similar to conventional concrete.

News Individual liquid screed Cemfloor

2022年7月7日 With over 50 years’ experience in the industry and more specifically 15 years in the liquid screed industry, Cemfloor and McGraths Limestone are industry leaders in the fast drying liquid screed market.

What is floor screed? EKA Concrete

2015年9月28日 Choosing the right floor screed contractor. To ensure you get the right type of screed and that it is laid correctly for the best finish and long lasting results, be sure to choose the right contractor. Your chosen concrete supplier should have extensive experience and a skilled team of concrete and screeding experts, as well as state of the

What’s the Difference Between Dry Screed and

2022年1月18日 Dry screed consists of aggregates (such as sand) and cement, with a ratio of between 3-5 parts aggregate and 1 part cement. This creates a thin, concrete-like substance that will clump together when

4 Types Concrete Screed Machine: Which One Is Best For

2022年6月7日 The concrete truss screed is a new type of equipment that uses the high quality gasoline engine. It is widely used in concrete pavement, bridge and ground engineering for concrete ground pulping, compaction and leveling. Its leveling effect is very good. The width of the road surface can be formed once in the range of 4-18 meters,

Floor screeding with lightweight concretes and

The Latermix Cem range of concretes can be used for base screeds that are strong and very lightweight (450 600 kg/m 3) and contribute significantly to the thermal insulation of the slab. Latermix Cem Classic and Maxi are no

What Is Concrete Screed Concrete Screed Specifications

2023年2月14日 Concrete Screed Curing and Dimension. Crack Free Screed. Clean. Dry. Flatness. Composition of Concrete Screed. A floor screed is usually a cementitious material made from a 1:3 or 1:4.5 ratio of cement to sharp sand. It may be applied onto either a solid in-situ concrete ground floor slab or onto a precast concrete floor unit.

Dry vs Liquid Floor Screed: Which One is Best For You?

Benefits of Liquid Floor Screed. Quicker application: It is comparatively quicker to apply and handle because it can be poured in one go and not applied piece by piece like you would with a dry screed. Energy efficient: Liquid screeds are more conductive than traditional screeds. The effort required to spread and distribute the floor evenly is

Concrete Screed AdvantagesApplication DAILY CIVIL

2023年3月7日 4. Once it is evenly spread and the required thickness is achieved, the screed surface is given a finish. Generally, a smooth surface finish is given to the surface of the concrete screed. But it also depends on the intended use. 5. The layer of concrete screed is left to dry for some time, similar to conventional concrete.

Factors to Consider When Choosing Laser Screeding

2023年2月14日 Learn how to choose the right laser screeding equipment for your construction project. Our article covers the key factors to consider, including project size, concrete type, surface finish, power source, budget, maintenance, and operator experience. Get the right equipment for a successful project.

Floor Screeding in Cambridge get it right first time!

2018年4月3日 Underfloor heating screeds /self levelling screeds Self-levelling screeds come into their own when used in vast industrial or commercial areas. Dry screed mix ratio is 1:3-5 = cement and sand. This is mixed with a water and a fibre additives to avoid cracking. Additional additives can be used ensuring a fast drying time.

Screeding Floor Screeding Floor Screeders

2023年2月13日 TYPES OF SCREED. Standard Screeds A mix of sand and cement which is ideal for normal residential use. 5 parts sand to 1 part cement is the usual mix for standard screed. The standard flooring screed will dry at a rate of 1mm thickness each day. Liquid or Self-Levelling Screeds A latex and cement material which can produce the highest

Exploring Screed Options On-Site Magazine

2022年5月25日 Depending on the slump and pipe length, a contractor can screed off 1,800 to 2,500 square feet of concrete with just one fully charged battery. Battery operation provides fume-free screeding for those working in closed off environments, or any area where fumes may be a concern. These also generally require less setup time, and no