Detailed Process Of Red Slag Powder Manufacturing

Recycling of ironmaking and steelmaking slags in Japan

2022年4月6日 The mass production of steel is inevitably accompanied by large quantities of slags. The treatment of ironmaking and steelmaking slags is a great challenge in the sustainable development of the steel industry. Japan and China are two major steel

Analysis and multi-objective optimization of slag powder

2020年7月1日 In the literature[5], a detailed analysis of the particle size has been carried out through 15. Li et al. (2020) applied MOO to build better soft sensors in a slag

Steel Slag an overview ScienceDirect Topics

Air-cooled steel slag may consist of big lumps and some powder. The mineral composition of cooled steel slag varies and is related to the forming process and chemical composition.

进一步探索

(PDF) The use of steel slag in concrete ResearchGate(PDF) Overview of Steel Slag Application and Utilization Re根据热度为您推荐•反馈

Metallurgical Slag an overview ScienceDirect Topics

A synthetic aggregate may also be the byproduct of manufacturing and a final burning process—blast furnace slag is an example of a synthetic aggregate. Briefly, blast furnace

Slag: From By-product to Valuable Construction Material

2014年7月29日 Slag is a by-product of the metallurgical smelting process. Slag has a double role: it permits removal of impurities, known as gangue, from the melt by forming

Making Slag an overview ScienceDirect Topics

In the first stage, slag making, FeS in matter is oxidized to generate white metal, an impure Cu 2 S melt. In the second stage, the white metal is oxidized to blister copper which

Basics of slag production Article on the slag industry

2011年10月27日 BOS Slag. Process. When molten iron (referred to as “hot metal”) from the blast furnace is to be converted into steel, the main tasks are the removal of carbon,

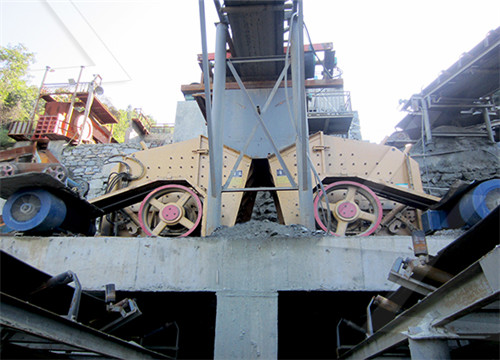

How to Process Slags (with detailed process)? Fote

2023年2月15日 Slag brick is made by mixing, watering, grinding and pressing slag and limestone. In the production process of slag brick, the particle size of the slag is generally

How to Start Chilly Powder Manufacturing

1 The processing of chilly powder is simple. Find below a basic process guide: 1. The material enters the crushing room from a hopper and is cut into powder by the high-speed blades. 2. Standard-size spice

(PDF) Lead Smelting Slag Processing ResearchGate

2021年2月28日 Fuming (slag s ublimation) is th e process o f reducing the treatment of liquid slags by blowing a mixture of air with a reducing agent (natural gas or coal dust) at

Materials Free Full-Text Orthogonal Experimental Study

2022年12月9日 Blast furnace slag is a solid waste produced in the process of blast furnace ironmaking. At present, the global annual output has exceeded 250 million tons [].In many developing countries, the comprehensive utilization rate of blast furnace slag is still at a low level, which seriously restricts the sustainable development of local economy and society

Study on hydration mechanism and environmental safety

2023年3月11日 Red mud (RM) cementitious materials were prepared with the thermally, thermoalkali- or thermocalcium-activated RM, steel slag (SS), and other additives. The effects of different thermal RM activation methods on the cementitious material hydration mechanisms, mechanical properties, and environmental risks were discussed and

Efficiency of Chemical and Biological Leaching of Copper

The chemical composition of copper slag depends on the treatment process and furnace type, and is typically 30–40% Fe, 35–40 The dried material was comminuted with an Eirich mixer to break the agglomerates and produce a fine powder (d80 < 54 µm; d50 < 29 µm) by Outotec. The detailed environmental characterization of the as

Red Mud-Blast Furnace Slag-Based Alkali-Activated Materials

2021年10月13日 The aluminum Bayer production process is widespread all over the world. One of the waste products of the Bayer process is a basic aluminosilicate bauxite residue called red mud. The aluminosilicate nature of red mud makes it suitable as a precursor for alkali-activated materials. In this work, red mud was mixed with different percentages of

Printability and physical properties of iron slag powder

2020年8月13日 There have been many studies on three-dimensional (3D) printing using metal compounds. However, 3D printing using a metal compound has disadvantages in that it increases the cost for supplying metal materials. A method of using slag which is a recyclable material has been proposed to reduce costs. With the growing demand for

Study on hydration mechanism and environmental safety

1 Red mud (RM) cementitious materials were prepared with the thermally, thermoalkali- or thermocalcium-activated RM, steel slag (SS), and other additives.

Use of Slags in the Production of Portland Cement Clinker

2019年8月28日 The X-ray phase analysis was performed via the powder diffraction technique using DRON-3 M. The process of devitrification for the blast furnace granulated slag has more expressed exothermic maximum, which is caused by high concentration of a glass phase. The open-hearth slag acts as a correcting ferrous additive, besides

Slag: From By-product to Valuable Construction Material

2014年7月29日 Slag is a by-product of the metallurgical smelting process. Slag has a double role: it permits removal of impurities, known as gangue, from the melt by forming oxides. It also allows exchange reactions with the liquid metal, permitting control of the process in order for the desirable elements to stay in the melt while the others are removed.

(PDF) Role of supplementary cementitious materials in self

2023年3月9日 SCC-a High Performance Concrete, is a product of continuous research and development undertaken in the domain of concrete mix design and admixtures. High cost of SCC limits its application

Study on hydration mechanism and environmental safety

2023年3月11日 Red mud (RM) cementitious materials were prepared with the thermally, thermoalkali- or thermocalcium-activated RM, steel slag (SS), and other additives. The effects of different thermal RM activation methods on the cementitious material hydration mechanisms, mechanical properties, and environmental risks were discussed and

Efficiency of Chemical and Biological Leaching of Copper

The chemical composition of copper slag depends on the treatment process and furnace type, and is typically 30–40% Fe, 35–40 The dried material was comminuted with an Eirich mixer to break the agglomerates and produce a fine powder (d80 < 54 µm; d50 < 29 µm) by Outotec. The detailed environmental characterization of the as

Full article: Understanding mould powders for

2016年11月29日 The development and application of mould powder for high-speed continuous casting of steel is described. For thin slab casting, the main requirements are proper powder melting, undisturbed slag

Study on hydration mechanism and environmental safety

1 Red mud (RM) cementitious materials were prepared with the thermally, thermoalkali- or thermocalcium-activated RM, steel slag (SS), and other additives.

Printability and physical properties of iron slag powder

2020年8月13日 There have been many studies on three-dimensional (3D) printing using metal compounds. However, 3D printing using a metal compound has disadvantages in that it increases the cost for supplying metal materials. A method of using slag which is a recyclable material has been proposed to reduce costs. With the growing demand for

(PDF) Role of supplementary cementitious materials in self

2023年3月9日 SCC-a High Performance Concrete, is a product of continuous research and development undertaken in the domain of concrete mix design and admixtures. High cost of SCC limits its application

Titanium production by magnesium thermal

2019年11月26日 Titanium and its alloys have extraordinary mechanical properties and low density, which makes them important materials in aerospace and other industries 1.Complexity and high energy

The process planning for additive and subtractive hybrid

2023年3月1日 1.Introduction. The early work of additive and subtractive hybrid manufacturing (ASHM) was conceptualized by R. Merz et al [1] and laser aided manufacturing process (LAMP) process form the University of Missouri [2].It combines the advantages of high design freedom of additive manufacturing (AM) and high surface

Insulation behavior of foamed based geopolymer as a

2023年3月8日 The foaming process increases the volume of the geopolymer mixture, resulting in the formation of a cellular structure. The development of foamed geopolymer was undertaken by using glass powder and copper slag. The glass cullet, which consisted mainly of broken bottles and car windshields, was collected from a local dump yard in

Numerical investigation of fiber orientations and

2023年3月6日 The packing characteristics of fiber/polymer powder in powder bed fusion additive manufacturing exhibit a high correlation with the mechanical varying the fiber length can provide an effective way to regulate fiber orientations in the powder packing process, which would help achieve satisfactory anisotropic mechanical properties for