Cement Crusher Unit Process Two Fan

Concrete Crush an overview ScienceDirect Topics

In a development quoted by (ITRC, 2008), a commercial Brokk 250 unit used a remotely operated, articulated, hydraulic boom with several end effectors, such as a hydraulic

Cement Production Process Cement Manufacturing

2020年8月25日 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker

Manufacturing process

2023年3月1日 Step 1: Mining. The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing,

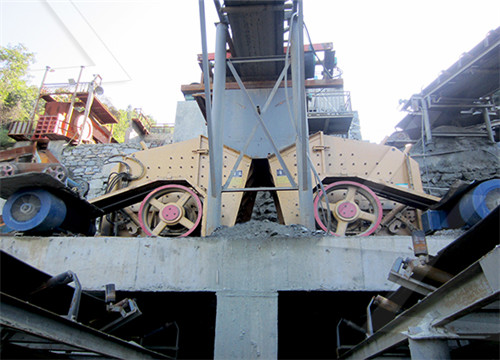

Cement Crusher Crusher In Cement Plant AGICO Cement

Hammer CrusherImpact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日 Small concrete crushers are mainly used for crushing with small output, and most of them are jaw crushers with fixed and mobile types. The feed size of the

Preheater In Cement Plant Cyclone Preheater AGICO

Cyclone preheater, also known as suspension preheater, is the main cement equipment commonly used in the new dry process cement production line. It is the main gas-solid

Production Process Home

Stage 8. Cement Grinding (with Gypsumadditives) Stage 9. Packing Dispatch. Cement manufacturing process can classified in to two types in thermal operation as wet process

m/sbm of crusher plant in cement units.md at main

Contribute to legaojm/m development by creating an account on GitHub.

Stone Crushing Plant Automatic Stone Crusher Plant

Stone Crushing Plant Technological Process. The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating

Ball MillRoller Press for Cement Grinding Process

Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement manufacturing plants and cement grinding plants. 1.

Energy consumption assessment in a cement production

2015年6月1日 Brunke and Blesl [4] evaluated the energy conservation and CO 2 abatement potential of 21 identified measures in a German cement production plant and concluded that the economical conservation and abatement potential for the year 2013 of 4% for fuel, 0.7% for electricity and 3.4% fuel and process-related CO 2 emissions

What Are The Cement Clinker Crushing Equipment?

2022年1月22日 Cone crusher is advanced crushing equipment in the mining field. Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation. In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further

(PDF) Design of Impact stone crusher machine

2019年5月31日 Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

RM 100GO! RUBBLE MASTER Mobile Crushers

1 The RM 100GO! is the powerful high performance mobile crusher among the mobile crushers, exceeding all your expectations. Weighing in at only 29 t when empty this is a particularly high-capacity machine which

Cement Manufacturing Process Phases Flow

2012年8月30日 Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone

(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

The grade of concrete considered for this study purpose is M20. It is found that as the age of aggregate crusher screen increases from 0-2 years, 2-4 years, 4-6 years and more than 6 years the fineness modulus increases it shows that older the crusher screen, the average particle size of coarse aggregates increases.

Ball MillRoller Press for Cement Grinding Process

Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement manufacturing plants and cement grinding plants. 1. Roller Press Cement Pre Grinding System. The most noticeable feature of the roller press cement pre-grinding system is that the fine material power ground at the middle

Cement Grinding Plant Overview Cement Grinding Unit

2019年10月11日 There are two types of cement mill including a ball mill and vertical cement mill. The packing machine is used to pack the finished cement product into a bag according to a certain weight. The dust collector is used to treat the dust generated during the cement grinding process to ensure that the dust emission reaches the national

(PDF) Stone Crushers and Dust Problem

2012年1月1日 Abstract. ABSTRACT Stones are used in all the facet of life of human beings. Rocks are broken into small pieces, in a stone crusher. Crushing of boulders lead to production of large quantity of

Concrete vs Cement: What's The Difference? Howden

2020年1月10日 People often use the terms ‘cement’ and ‘concrete’ interchangeably. Which is similar to using the words ‘’ and ‘cake’ interchangeably. It’s not the same thing. Cement, like , is an ingredient. To make concrete a mixture of portland cement (10-15%) and water (15-20%) make a paste. This paste is then mixed with

Size Reduction of Solids Crushing and Grinding Equipment

The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology. It is estimated that mechanical size reduction of rocks, ores, coals, cement, ,...

Cement ProcessEnergy Saving ECCJ

2010年6月24日 Cement ProcessEnergy Saving October, 2006 The Energy Conservation Center, Japan Taichiro Kawase. Laos 2006.10 2 F Fan EP Electrostatic Precipitator SP Suspension Preheater stack fuel exhaust gas air Suspension Crusher Dryer Figure 1 Cement Production Process Dry Powder Mixer Weigher Raw Mill

Cement Extraction and processing Britannica

Extraction and processing. Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.. The

Cement Crusher Crushers for Cement Plant AGICO

Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper size particles. AGICO offers 4 types of crushers for cement plants : hammer crusher,jaw crusher,impact crusher,and cone crusher .

181 Process Flow Diagram (PFD) Symbols for Engineers

1 Process Flow Diagram Equipment Symbols. Flow chart symbols use different shapes to represent different components, such as equipment, valves, instruments, and piping flow. There is a standardized set of flowchart symbols. Process Flow Diagram equipment symbols include centrifuges and heat exchangers.

Stone Crushing Plant Automatic Stone Crusher Plant

Stone Crushing Plant Technological Process. The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment. The designed output is generally 30-350 tons per hour. According to different technological

Choosing a mobile impact crusher for recycling what you

2021年3月12日 March 12, 2021. The McCloskey I54 Impactor is designed for high quality and high production capacity in mobile applications, built around a 47- x 53.5-inch four bar impactor chamber with a 37- x 53.5-inch feed opening. RPN connected with product experts and Canadian distributors representing eight of the leading global manufacturers of

(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

The grade of concrete considered for this study purpose is M20. It is found that as the age of aggregate crusher screen increases from 0-2 years, 2-4 years, 4-6 years and more than 6 years the fineness modulus increases it shows that older the crusher screen, the average particle size of coarse aggregates increases.

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.) Obtaining the size or surface area required for the enrichment stage. In general, crushing is carried out in

Chemical Processing 101: Crushing Howard

Howard Industries is a one-stop shop when it comes to chemical processing. Our specialized equipment can handle it all, from crushing oversized materials to hardened materials. Not only that, but we can also continue

- 南宁哪里磨粉机卖

- 广东有卖石英石加工机械的公司吗

- China Best High Quality Mining Ball Grinding Mill With Low Price

- 切屑破碎机

- 雷门磨机销售商破碎机

- 德阳盐城吉林玻璃钢夹砂管生

- 砂金的工业品味

- 100TPH颚式细破机哈尔滨农垦北辰废钢破碎机厂

- 9092 Model Stone Cone Mining Mill

- 新型液压圆锥破碎机

- 砂石料仓棚上的安全标语

- 2014new Type Huazn Japanese Technology Astro J E Jaw Crusher

- 国产破碎锤咋样

- Moagem De Granito Granito Planta De Produo De Rocha

- MU10烧结页岩砖是属于什么