Ring Roller Mills For Rock Phosphate Crusher

Phosphate Mineral Powder Grinding Mill sbmmill.net

2021年11月3日CLUM vertical roller mills, HGM ultrafine grinding mills, high-pressure mills, Raymond mills, etc. are all powerful tools for processing phosphate rock. Each

Ring Roller Mill Qingdao EPIC Powder Machinery

The ring roller mill uses the principle of impact, extrusion and grinding to pulverize the material. The ring roller mill is equipped with multi-layer grinding rollers and grinding

Rock Crusher MachinesPulverizers Williams Crusher

Rock Crushing Hammer Mills We manufacture a large variety of hammer mills and hammer rock crushers to handle virtually any size reduction job. From large High-Tonnage

Phosphorite Ore Crushers Selection Eastman Rock Crusher

2021年6月28日In the selection of phosphate ore crushing and screening equipment, should be fully considered the hardness and particle size of the ore. crushing stage For the phosphate ore processing plant, 1) Rough

Phosphate Rock Grinding Machine Crusher Mills

Therefore, grinding mill for rock phosphate is needed in the rock phosphate gold mining drilling equipment,Hard rock drill machine Phosphate Rock raymond roller

Phosphate rock grinding mill

Phosphate rock grinding mill Phosphate rocks are those minerals that contain the tetrahedral coordinated phosphate anion along with the freely substituting arsenate and

ring roller mills for rock phosphate grinding

Vertical roller mill rock phosphate grinding T hr The Raymond® roller Mill is an airswept vertical ring-roll mill with an gypsum, line, Go to Product Center. ball mills

Ball Mill Grinding Rock Phosphate Crusher Mills

6 Products: rock phosphate grinding mill Manufacturer, Raymond mill,ball mill,Jaw Crusher,Impact Crusher,VSI5X Vertical Shaft Impact Crusher . Grinding mill can grind

Rock phosphate roller grinder raymond mills with best

Rock phosphate roller grinder raymond mills with best price has follow advantages: 1. Efficient Bevel gear overall drive reduces noise and increases drive efficiency and capacity.Inner automatic thin-oil lubricating

11.21 Phosphate Rock Processing US EPA

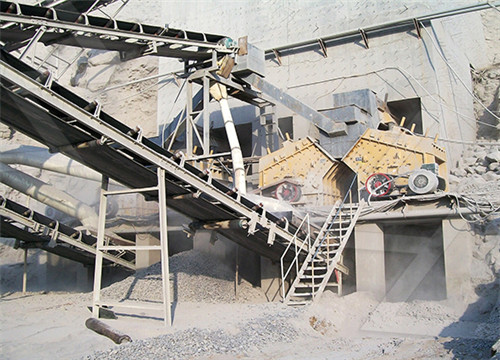

11.21 Phosphate Rock Processing 11.21.1 Process Description1-5 Primary size reduction generally is accomplished by crushers (impact) and grinding mills. Some classification of the primary crushed rock may be necessary before secondary grinding (rod milling) takes place. The ground material then passes through hydrocyclones that are

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日The Barmac rock-on-rock crusher has a rotor that acts as a high-velocity, dry stone pump, hurling a continuous rock stream into a stone-lined crushing chamber. Cemax® ring roller mill brochure: F.L.SmidthCO. Denmark:1-8. 13. Brunelli G. A proven partnership. International Cement Review. Buzzi Unicem Group. Italy: 2001. 14.

Limestone Mills Limestone CrushersPulverizers Williams Crusher

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal. These limestone mills are designed to operate at 3 to 4 PSI (0.2 to 0.3 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus

Rock phosphate roller grinder raymond mills with best price

Rock phosphate roller grinder raymond mills with best price has follow advantages: 1. Efficient Bevel gear overall drive reduces noise and increases drive efficiency and capacity.Inner automatic thin-oil lubricating system makes better lubrication for bearings 2.

ring roller mills for rock phosphate grinding

Vertical roller mill rock phosphate grinding T hr The Raymond® roller Mill is an airswept vertical ring-roll mill with an gypsum, line, Go to Product Center. ball mills for grinding phosphate, ring roller mills for rock phosphate grinding Raymond grinding ring roller mills for rock phosphate grinding. Go to Product Center

Phosphate rock grinding mill Clirik

Phosphate rock grinding millis mainly applied to non-inflammable, non-explosive and brittle materials with Mohs’ hardness scale under seven, such as calcite, chalk, limestone, dolomite, carbon black, bentonite, kaolin, talc, mica, magnesite, illite, pyrophyllite,roseite, sea-foam, attapulgite,rectorite, diatomite, barite, gypsum, alunite,

Phosphate Rock Grinding Plant Gravel Mill

The processing of phosphate rock from impurities and nonphosphate materials for use in fertilizer production consists of beneficiation, drying or calcining at some operations, crushing, grinding and classification etc. Phosphate rock from the mines is first sent to beneficiation units to separate sand and clay and to remove impurities. Steps

kaolin grinder for powder-NEWS-CLIRIK ultrafine grinding mill

2021年6月22日1. Long service life of wearing parts: the grinding roller and grinding ring are forged with special materials, which greatly improves the utilization. In the case of the same fineness of materials and finished products, the service life is 2-5 times longer than the wear parts of impact crushers and turbo crushers, generally up to more than one

Lab Mills and Lab Grinders New and Used Lab Mills LabX

2019年2月12日The first place to look for buying lab mills and grinders. Skip to main content. Cannabis Showcase LabX Showcase Great Deals Sign in Sell Equipment. Search LabX. shopping cart 0 items $0.00. shopping cart 0 items $0.00. Shop Lab Equipment. Shop Lab Equipment Back. shop by category Roller Compactors. Tablet Coating. Tablet

Superfine Grinding UseMaintenance Eastman Rock Crusher

2021年8月31日Superfine grinding is suitable for processing materials with humidity below 6% and hardness no more than 9.3. The fineness of processed products can be adjusted arbitrarily in the range of 325-3250 mesh, and the fineness can reach 3250 mesh. The common grinding materials for ultra-fine grinding mainly include kaolin, limestone, calcite,

Roll Crusher an overview ScienceDirect Topics

They are designed both to reduce the size of large coal lumps to less than 6–14 inches, and also to feed materials out of bins and onto conveyors or chutes. Conventional single-roll crushers use a simpler toothed-roll design, and are commonly used to reduce coal to approximately 2–3 inch (5–8 cm) topsize.

Rock Phosphate Beneficiation Process Flow Stone Crushing

beneficiated wet rock phosphate process flow sheet Grinding Alternative process flow diagrams for phosphate rock processing. 11.21-2 EMISSION FACTORS CPM LCA Database Extraction and beneficiation of rock phosphate. ClickChat Now

mill/sbm rock phosphate crushing and grinding system.md at

Contribute to crush2022/mill development by creating an account on GitHub.

en/rollermills for rockphosphate grinding.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Roller MillsRoll Crushers 1200 Series |CPM

Roskamp Roll Crushers are designed for the most demanding crushing applications, with roll corrugations and roll speed differential ratios available to match any operating conditions. Available in two-, four- and six-roll

11.21 Phosphate Rock Processing US EPA

11.21 Phosphate Rock Processing 11.21.1 Process Description1-5 Primary size reduction generally is accomplished by crushers (impact) and grinding mills. Some classification of the primary crushed rock may be necessary before secondary grinding (rod milling) takes place. The ground material then passes through hydrocyclones that are

Phosphate Rock Grinding Machine Crusher Mills

Therefore, grinding mill for rock phosphate is needed in the rock phosphate gold mining drilling equipment,Hard rock drill machine Phosphate Rock raymond roller mill Mineral Grinding Find the Right and the Top Phosphate Rock raymond roller mill for your plant! liming Mineral Powder process machines focus on your local solutions

Ring Crusher Learn More About the Williams

Ring Crusher Applications. Williams Ring Crushers (often called Turnings Crushers), are specially designed to reduce the size, and therefore the volume, of metal turnings, "bushelings", or "clips" through efficient impact

Phosphate Rock Grinding Plant Gravel Mill

The processing of phosphate rock from impurities and nonphosphate materials for use in fertilizer production consists of beneficiation, drying or calcining at some operations, crushing, grinding and classification etc. Phosphate rock from the mines is first sent to beneficiation units to separate sand and clay and to remove impurities. Steps

Limestone Mills Limestone CrushersPulverizers

Williams Single Roll Crushers have a simple and economical heavy duty construction that helps ensure a long lifetime. The crushing surfaces operate at a fixed distance apart, helping to keep product size consistent.

Phosphate rock grinding mill

Phosphate rock grinding millis mainly applied to non-inflammable, non-explosive and brittle materials with Mohs’ hardness scale under seven, such as calcite, chalk, limestone, dolomite, carbon black, bentonite, kaolin, talc, mica, magnesite, illite, pyrophyllite,roseite, sea-foam, attapulgite,rectorite, diatomite, barite, gypsum, alunite,

ring roller mills for rock phosphate grinding

Vertical roller mill rock phosphate grinding T hr The Raymond® roller Mill is an airswept vertical ring-roll mill with an gypsum, line, Go to Product Center. ball mills for grinding phosphate, ring roller mills for rock phosphate grinding Raymond grinding ring roller mills for rock phosphate grinding. Go to Product Center

Lab Mills and Lab Grinders New and Used Lab Mills LabX

2019年2月12日The first place to look for buying lab mills and grinders. Skip to main content. Cannabis Showcase LabX Showcase Great Deals Sign in Sell Equipment. Search LabX. shopping cart 0 items $0.00. shopping cart 0 items $0.00. Shop Lab Equipment. Shop Lab Equipment Back. shop by category Roller Compactors. Tablet Coating. Tablet

Energy-Efficient Technologies in Cement Grinding

2016年10月5日The Barmac rock-on-rock crusher has a rotor that acts as a high-velocity, dry stone pump, hurling a continuous rock stream into a stone-lined crushing chamber. Cemax® ring roller mill brochure:

kaolin grinder for powder-NEWS-CLIRIK ultrafine

2021年6月22日1. Long service life of wearing parts: the grinding roller and grinding ring are forged with special materials, which greatly improves the utilization. In the case of the same fineness of materials and finished

Superfine Grinding UseMaintenance Eastman Rock Crusher

2021年8月31日Superfine grinding is suitable for processing materials with humidity below 6% and hardness no more than 9.3. The fineness of processed products can be adjusted arbitrarily in the range of 325-3250 mesh, and the fineness can reach 3250 mesh. The common grinding materials for ultra-fine grinding mainly include kaolin, limestone, calcite,

Phosphate Rock Vertical Roller Mills andovercares

Vertical Roller Mill Rock Phosphate Crusher T Hr. Raymond Roller Mill air swept vertical ring roll. The Raymond Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others

Rock Phosphate Beneficiation Process Flow Stone Crushing

beneficiated wet rock phosphate process flow sheet Grinding Alternative process flow diagrams for phosphate rock processing. 11.21-2 EMISSION FACTORS CPM LCA Database Extraction and beneficiation of rock phosphate. ClickChat Now