Africa Stone Circular Vibrating Grizzly Screen 4yk1235

Grizzly Scalping Screens Astec

Grizzly Scalping Screens Grizzly Scalping Screens Overview Downloads Specs Features Request Info Where to buy Overview Featuring a rugged, heavy-duty design, Astec

进一步探索

small grizzly gravel screen project Heavy Equipment ForUSED GRIZZLY SCREEN 8′ x 12′ Dogface Heavy EquipmGrizzly Screens For Sale John Richards ConstructionUsed Static Grizzly Screens for sale. Grizzly equipmentUsed Grizzly Screens for sale. Metso equipmentmore M根据热度为您推荐•反馈

Grizzly Screens JVI Vibratory Equipment

Efficiently Screen and FeedDissimilar Sized Material. JVI Electromechanical Vibratory Grizzly Screens, also known as Grizzly Feeders, are a heavy-duty solution for efficiently

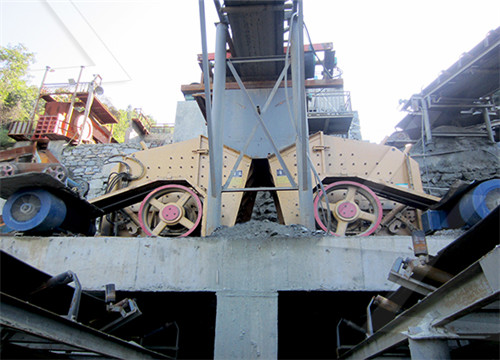

Circular Vibrating Screen China First Engineering

Circular Vibrating Screen Features: 1.The cylinder eccentric shaft and eccentric block are adopted to adjust the amplitude, effectively increasing the excitation force and production

Circular vibrating screen used for mining &construction 4YK1235

Circular vibrating screen used for mining &construction 4YK1235 XBM Products Made In China, China Manufacturer. 1. Brief introduction of Circular Vibrating Screen Vibrating

FINGER-SCREEN™ Vibrating Grizzly Screen General Kinematics

The FINGER-SCREEN™ Grizzly Screen provides a pan component at the feeder that begins to separate the material. Mounted on springs, the feeder is vibrated, causing the

Vibrating Grizzly Feeders Astec

Astec vibrating grizzly feeders incorporate a heavy-duty vibrator assembly with cast shafts, open housing, flow-through oil lubrication, double-row spherical roller bearings and

GRIZZLY Screen ? JÖST GmbH + Co. KG

GRIZZLY screens are used as a primary separator for the preliminary separation of material in front of jaw crushers. TECH INFO DOWNLOAD QUESTIONNAIRE DOWNLOAD

ELEKTROMAG-JOEST GRIZZLY Screen

GRIZZLY screens are used as a primary separator for the preliminary separation of material in front of jaw crushers. TECH INFOS DOWNLOAD QUESTIONNAIRE DOWNLOAD

Static Grizzly Screen as a Rock Separator Mineral

2015年7月25日Vibrating Grizzly Screen. A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use. It

Vibrating Screens, Vibrating Grizzlys, Vibrating Feeders Vipro

Polyurethane Panels: Vipro manufacture and supply the full range of polyurethane panels. The most popular size supplied is 305 x 305 mm (1x1 ft) and 31 mm thick. Other

Circular Vibrating Screen China First Engineering Technology

Circular vibrating screen is a kind of screening equipment with multiple layers of screen and circular vibrating track. The flow distance of raw materials on the screens is long, the screening grades are multiple, and the screening effect is excellent. 4YK1235: 4: 11: 4500×1967×2040: YK1545: 1: 17.5: 6.75: 970: 6.0-8.0: 25-240: 11: 5030×

Stationary ScreensMedia, Stationary Screen Series

stationary screens have been tried and tested worldwide in order to provide you with the most reliable equipment. Economic and easy-to-use stationary screens with robust vibrating grizzlies and scalpers cover a range of applications. Whether you need an individual unit or a complete system, we deliver.

FINGER-SCREEN™ Vibrating Grizzly Screen General Kinematics

Features: FINGER-DECKS offer a non-blinding design compared to wire mesh screens. Optional cascading decks improve screening efficiency. Modular decks are easy to replace. Using a single vibratory motor, there is virtually no maintenance required. Will fit into your existing footprint. Can be set-up to feed into your primary crusher.

Vibrating Grizzly Feeders Astec

Astec vibrating grizzly feeders incorporate a heavy-duty vibrator assembly with cast shafts, open housing, flow-through oil lubrication, double-row spherical roller bearings and precision-cut gears.

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日PURPOSE OF VIBRATING SCREENS. Screens are used mainly for the following purposes: Scalping. By scalping it is meant screening of coarse material in order to remove the undersize, typically before a primary crusher. Because of the coarse feed the top deck, which may be the only one, is often of a grizzly type. i.e. grizzly bars as opposed

Vibrating Grizzly Feeders ScreeningSeparating Rock

Vibrating grizzly feeders for rock, sand, dirt and gravel, engineered for your material handling needs at Rock Systems. Available for sale, rent, or lease. Vibrating Screens; Vibrating Grizzly Feeders; Static Grizzly Screens; Vibrating Grizzly Feeders. Trio Model TF4620-1 46" Wide x 20' Long Vibrating Inventory Number: C2447.

Static Grizzly Screen as a Rock Separator Mineral Processing

2015年7月25日A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use. It combines the functions of screening and feeding the ore to the primary crusher, and, by eliminating the undersize product in the ore feed to the crusher, materially increases the crusher capacity.

Vibrating Screens, Vibrating Grizzlys, Vibrating Feeders Vipro

Polyurethane Panels: Vipro manufacture and supply the full range of polyurethane panels. The most popular size supplied is 305 x 305 mm (1x1 ft) and 31 mm thick. Other sizes are available and can be sourced on request. Aperture sizes typically range from 0.2 100 mm for slotted and 0.8 232 mm for square apertures.

Screening/Sizing McLanahan

Screens can also be used in other stages of the processing plant to produce a final, saleable product, as well as to dewater washed material to less than 14 percent moisture for easy conveying and/or stockpiling. To size and separate material, screening equipment employs a vibrating or tumbling action that causes the feed material to divide by

Vibrating Equipment Vibemek

Designed to screen at much faster rates with fine mesh as compared to standard vibrating screens. It can provide up to 3 times higher throughput compared to standard vibrating equipment. This is made possible by a unique design that generates higher g-forces at a higher frequency and lower amplitude.

Circular Vibrating Screen Circular Vibrating Sieve Circular

GTEK YK circular vibrating screen is a high performance screen that can be used in a wide range of industries such as mining, sand, gold, energy and construction. GTEK YK circular vibrating screens are manufactured as 1, 2, 3 or 4 decks classification of ore, coal, rock and gravel or any material to be separated on its size. FeaturesBenefits. 1.

Types Of Vibrating Screens Introduction And Difference

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width from 4′-12′ to 8′-32′. The screen size is usually set to 2.5 times its length and width. The width of the sieve

AViTEQ: Screening technology

They reliably separate small from large, heavy from light, solid from liquid, and mixtures of different shapes or materials as well. Depending on the bulk material, the desired task dewatering, screening or classifying and the available space, AViTEQ offers a variety of conventional solutions. Vibrating screens. Circular vibrating screens.

JOEST South Africa Home

JOEST Vibrating Systems Pty Ltd. is the African entity of the worldwide JOEST group, a dynamic and flexible corporation with more than 95 years of experience in vibratory equipment and bulk material handling solutions. Centrally located in Pretoria, JOEST South Africa locally manufactures and distributes the full JOEST product range of

Circular Vibrating Screen Circular Vibrating Sieve

GTEK YK circular vibrating screen is a high performance screen that can be used in a wide range of industries such as mining, sand, gold, energy and construction. GTEK YK circular vibrating screens are

Circular Vibrating Screen China First Engineering Technology

Circular vibrating screen is a kind of screening equipment with multiple layers of screen and circular vibrating track. The flow distance of raw materials on the screens is long, the screening grades are multiple, and the screening effect is excellent. 4YK1235: 4: 11: 4500×1967×2040: YK1545: 1: 17.5: 6.75: 970: 6.0-8.0: 25-240: 11: 5030×

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日PURPOSE OF VIBRATING SCREENS. Screens are used mainly for the following purposes: Scalping. By scalping it is meant screening of coarse material in order to remove the undersize, typically before a primary crusher. Because of the coarse feed the top deck, which may be the only one, is often of a grizzly type. i.e. grizzly bars as opposed

Vibrating Grizzly Feeders ScreeningSeparating Rock

Track/Portable Screen Plants Stationary-Skid Mounted Screen Plants Vibrating Screens Vibrating Grizzly Feeders Static Grizzly Screens Vibrating Grizzly Feeders Trio Model TF4620-1 46" Wide x 20' Long Vibrating Inventory Number: C2447 View Details Trio Model TF5224-2 52" Wide x 24' Long Vibrating Inventory Number: C2487 View Details

Static Grizzly Screen as a Rock Separator Mineral Processing

2015年7月25日A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use. It combines the functions of screening and feeding the ore to the primary crusher, and, by eliminating the undersize product in the ore feed to the crusher, materially increases the crusher capacity.

Vibrating Screens, Vibrating Grizzlys, Vibrating Feeders Vipro

Polyurethane Panels: Vipro manufacture and supply the full range of polyurethane panels. The most popular size supplied is 305 x 305 mm (1x1 ft) and 31 mm thick. Other sizes are available and can be sourced on request. Aperture sizes typically range from 0.2 100 mm for slotted and 0.8 232 mm for square apertures.

Screening/Sizing McLanahan

Screening equipment plays a large and important role in a processing plant. It can greatly affect your plant’s capacity, as well as the quality of your products. Screening equipment can be stationary or portable, designed for quick setup

Vibratory Screens : Innovations in Screen Designs

2022年6月27日Electromagnetically- Driven Grizzly Screen Grizzly screen is often used for pre-screening before coarse and medium crushing of materials. The mesh size is generally >50mm, but sometimes 25mm. Although the grizzly screen has a straightforward and sturdy construction, zero power consumption, no moving parts, minimal equipment

Circular vibrating screens Circular-motion vibrating screens

Working principle: Circular vibrating screens operate using indirect excitation of the screen mesh. The entire screen frame is driven by unbalance masses, which produce a circular vibrating motion. Another key feature: The directionless vibrations of the circular vibrating system have a steep launch angle and the screen area must be further

Types Of Vibrating Screens Introduction And Difference

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width from 4′-12′ to 8′-32′. The screen size is usually set to 2.5 times its length and width. The width of the sieve

JOEST South Africa Home

JOEST Vibrating Systems Pty Ltd. is the African entity of the worldwide JOEST group, a dynamic and flexible corporation with more than 95 years of experience in vibratory equipment and bulk material handling solutions. Centrally located in Pretoria, JOEST South Africa locally manufactures and distributes the full JOEST product range of

AViTEQ: Screening technology

They reliably separate small from large, heavy from light, solid from liquid, and mixtures of different shapes or materials as well. Depending on the bulk material, the desired task dewatering, screening or classifying and the available space, AViTEQ offers a variety of conventional solutions. Vibrating screens. Circular vibrating screens.

circular vibrating screen,YK series circular vibrating screens

Circular vibrating sieve machine is mainly composed of screen box, screen mesh, vibrator, damping spring device, chassis. Cylinder eccentric shaft vibration exciter and partial block help to adjust the amplitude of the vibrator is mounted on the side panel of the screen box is rotated by the motor through the V-belt to produce centrifugal force

Circular Vibrating Screen china-cfc.cc

Introduction. Circular vibrating screen is suitable for various screening operations such as heavy, medium and fine screening. It is an ideal equipment for processing materials after primary crushing and secondary crushing, and can also be used to screen finished products.The circular vibrating screen is used for classification and screening of