Cement Mill Ears Dynamic Behavior Of Closed Grinding System

Dynamic behavior of closed grinding systems and

The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations. The

Dynamic behavior of closed grinding systems and

2009年12月1日Dynamic behavior of closed grinding systems and effective PID parameterization Authors: Dimitris Tsamatsoulis Halyps Building Materials S.A. Abstract

(PDF) Modeling of Cement Milling Process Based on Long

2011年7月1日Key-Words: Dynamics, Cement, Mill, Grinding, Mo del, An electronic ear in the mill inlet. (4) Dynamic behavior of closed

Dynamic behavior of closed grinding systems and model uncertainty

The object of the present study is to investigate the dynamic of closed circuit cement mills. The model that has been developed, involving integral part and a first order filter,

Dynamic behavior of closed grinding systems and effective PID

2009年12月1日The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three

Dynamic behavior of closed grinding systems and

The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations. The

cement mill ears, dynamic behavior of closed grinding systems

cement mill ears, dynamic behavior of closed grinding systems. 时间/time:2018-01-30 12:55. Dynamic Behavior of Closed Grinding Systems Dynamic Behavior of

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

nents of a closed grinding system, is demonstrated in Figure 1. In the current automation one of the following is usually selected as a process variable: (1) The power of the

Dynamic behavior of closed grinding systems and model

Dynamic behavior of closed grinding systems and model uncertainty. Author: Dimitris Tsamatsoulis. Halyps Building Materials S.A., Italcementi Group, Korinth, Greece

Cement mill Wikipedia

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and

Dynamic behavior of closed grinding systems and effective PID

The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations. The model that has been developed, consisting of integral part, time

Dynamic behavior of closed grinding systems and effective

2009年12月1日The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations.

Optimizing the control system of cement milling:

2014年3月1日Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The process simulation is...

Dynamic behavior of closed grinding systems and effective PID

As significant sources of model uncertainty are determined the grinding of various cement types in the same cement mill and the decrease of the ball charge during the time. The Internal Model Control (IMC) and M Constrained Integral Gain Optimization (MIGO) methods are utilized to adjust the controller parameters.

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY

Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modeling. (December 2007) Gleb Gennadievich Mejeoumov, B.S., Ivanovo State Power University, Russia; M.S., Ivanovo State Power University, Russia Chair of Advisory Committee: Dr. Dan Zollinger Grinding of clinker is the last and most energy-consuming

cement mill ears, dynamic behavior of closed grinding systems

cement mill ears, dynamic behavior of closed grinding systems. 时间/time:2018-01-30 12:55. Dynamic Behavior of Closed Grinding Systems Dynamic Behavior of Closed Grinding Systems and Effective PID Parameterization . TSAMATSOULIS DIMITRIS . Halyps Building Materials S.A., Italcementi Group.

Dynamic behavior of closed grinding systems and model

The object of the present study is to investigate the dynamic of closed circuit cement mills. The model that has been developed, involving integral part and a first order filter, is based exclusively on industrial data sets of three cement mills routine operation, collected in a up to one year period. The model parameters uncertainty is also assessed varying

Dynamic behavior of closed grinding systems and model

Dynamic behavior of closed grinding systems and model uncertainty. Author: Dimitris Tsamatsoulis. Halyps Building Materials S.A., Italcementi Group, Korinth, Greece

Predictive Control of a Closed Grinding Circuit System in Cement

2017年10月12日This stone presents the development of a nonlinear model predictive controller (NMPC) applied to a closed grinding circuit system in the cement industry. A Markov chain model is used to characterize the cement grinding circuit by modeling the ball mill and the centrifugal dust separator. The probability matrices of the Markovian model

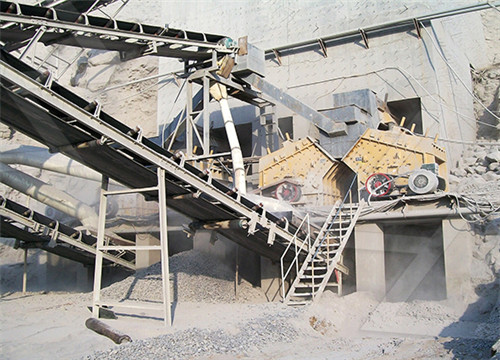

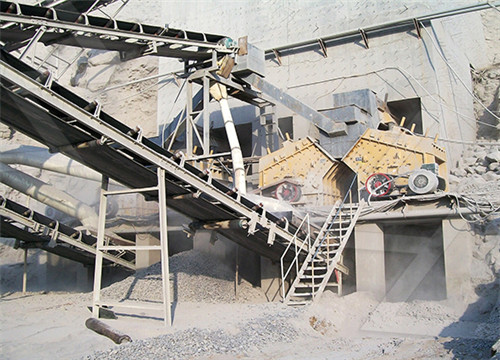

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption was on higher side. 3.1 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners

Coarse Return Prediction in a Cement Industry’s Closed Grinding

2021年2月3日In the next section, we describe a real-world cement industry’s closed grinding circuit system use case and the data collection campaign alongside the proposed FCDNN model. This will be followed by a review of the deployed model’s behavior in the dynamics of the complex operations and prediction results.

Dynamic Behavior of Closed Grinding Systems and Effective PID

CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract:- The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations.

Figure 33 from Dynamic behavior of closed grinding systems

Corpus ID: ; Dynamic behavior of closed grinding systems and effective PID parameterization @article{Dimitris2009DynamicBO, title={Dynamic behavior of closed grinding systems and effective PID parameterization}, author={Tsamatsoulis Dimitris}, journal={WSEAS Transactions on Systems and Control archive}, year={2009},

Reducing energy consumption of a raw mill in cement industry

2012年6月1日In this study, the first and second law analysis of a raw mill is performed and certain measures are implemented in an existing raw mill in a cement factory in order to reduce the amount of energy consumption in grinding process. The first and second law efficiencies of the raw mill are determined to be 61.5% and 16.4%, respectively.

Dynamic behavior of closed grinding systems and effective PID

The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations. The model that has been developed, consisting of integral part, time

Dynamic behavior of closed grinding systems and model

The object of the present study is to investigate the dynamic of closed circuit cement mills. The model that has been developed, involving integral part and a first order filter, is based exclusively on industrial data sets of three cement mills routine operation, collected in a up to one year period. The model parameters uncertainty is also assessed varying

Predictive Control of a Closed Grinding Circuit System in Cement

2017年10月12日This stone presents the development of a nonlinear model predictive controller (NMPC) applied to a closed grinding circuit system in the cement industry. A Markov chain model is used to characterize the cement grinding circuit by modeling the ball mill and the centrifugal dust separator. The probability matrices of the Markovian model

Dynamic behavior of closed grinding systems and model

Dynamic behavior of closed grinding systems and model uncertainty. Author: Dimitris Tsamatsoulis. Halyps Building Materials S.A., Italcementi Group, Korinth, Greece

Dynamic behavior of closed grinding systems and effective PID

As significant sources of model uncertainty are determined the grinding of various cement types in the same cement mill and the decrease of the ball charge during the time. The Internal Model Control (IMC) and M Constrained Integral Gain Optimization (MIGO) methods are utilized to adjust the controller parameters.

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY

Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modeling. (December 2007) Gleb Gennadievich Mejeoumov, B.S., Ivanovo State Power University, Russia; M.S., Ivanovo State Power University, Russia Chair of Advisory Committee: Dr. Dan Zollinger Grinding of clinker is the last and most energy-consuming

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 1.5 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance in-terms of system availability and output, however power consumption was on higher side. 3.1 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners

28 Simulation of Cement Grinding Process for Optimal

within the mill circuit, cement sampling and measurement, and the control func-tion applied. A simplified flow sheet, showing the basic components of a closed grinding system is presented in Fig. 1. The raw materials via weight feeders are fed to the ball mill (CM). The product of the mill outlet is directed through a recycle

cement mill ears, dynamic behavior of closed grinding systems

cement mill ears, dynamic behavior of closed grinding systems. 时间/time:2018-01-30 12:55. Dynamic Behavior of Closed Grinding Systems Dynamic Behavior of Closed Grinding Systems and Effective PID Parameterization . TSAMATSOULIS DIMITRIS . Halyps Building Materials S.A., Italcementi Group.

Coarse Return Prediction in a Cement Industry’s Closed Grinding

2021年2月3日In the next section, we describe a real-world cement industry’s closed grinding circuit system use case and the data collection campaign alongside the proposed FCDNN model. This will be followed by a review of the deployed model’s behavior in the dynamics of the complex operations and prediction results.

Figure 27 from Dynamic behavior of closed grinding systems

Corpus ID: ; Dynamic behavior of closed grinding systems and effective PID parameterization @article{Dimitris2009DynamicBO, title={Dynamic behavior of closed grinding systems and effective PID parameterization}, author={Tsamatsoulis Dimitris}, journal={WSEAS Transactions on Systems and Control archive}, year={2009},

The Decision Algorithm of Cement Mill Operation Index Based on

2023年1月25日The cement grinding system consists of a coarse grinding system mainly by roller press and a fine grinding system by ball mill, the energy flow in the grinding process moves along the material and gas paths, as shown in Fig. 2, which shows the equipment composition and production diagram of the cement grinding system,

Dynamic Behavior of Closed Grinding Systems and Effective PID

CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): Abstract:- The object of the present study is to investigate the dynamic of closed circuit cement mills and based on that to tune robust PID controllers applied to three actual installations. The model that has been developed, consisting of integral part, time delay and a first order

Reducing energy consumption of a raw mill in cement industry

2012年6月1日Raw mills are used to grind the raw materials into the farine which is the semi product of clinker. It is then fed to the rotary burners which transforms it into clinker which is the semi product of cement. After the grinding process in a cement mill, the production process completes.