Copper Beneficiation Machine Used In Process

How to Process Copper Ore: Beneficiation Methods and

进一步探索

Copper MiningExtraction Process Flow ChartCopper Ore Processing MethodsCopper Mining and Processing: Everything you Need to KCopper Beneficiation Process,Copper Refining Process,copCopper Sulfide Ore and Flotation Process JXSC Mining根据热度为您推荐•反馈

How to process copper ore: beneficiation methods and

2022年12月14日The specific beneficiation method used to process a copper ore will depend on the nature of the ore and its impurities. The equipment used will also vary,

Copper Beneficiation Process, Equipment Mineral Processing

Copper ore beneficiation is a process to extract copper from raw ores. Commonly used copper ore beneficiation process include gravity separation, flotation process, and

COPPER Copper production TU Delft

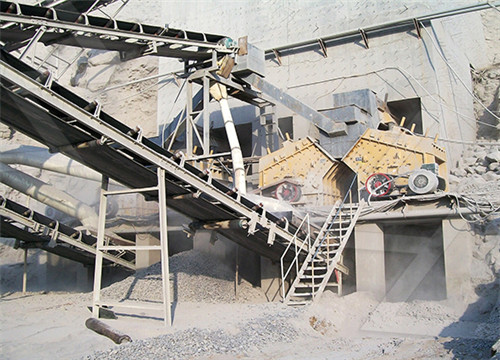

Typical equipment for crushing to about 20 cm are gyratory and cone crushers. density, and other properties are installed. Figure 4 gives an overview of a typical beneficiation

Energy and Environmental Profile of the U.S. Mining

5.1.2 Copper Beneficiation and Processing The two major processes employed in the United States to recover copper from ores are classified as either (1) pyrometallurgical

Copper Beneficiation Process,Copper Refining

Copper Ore Beneficiation Technology Kaolin Beneficiation Technology and Process Flow Iron Ore Hematite Separation Process Gold CIL Production Line Scheelite Flotation Production Line Phosphate Flotation

Mineral Processing Equipment Multotec

Strategic stockholdings of equipment and spares to respond to your plant requirements quickly and efficiently. Today, Multotec mineral processing equipment is used in over 100 countries on 6 continents, and by the

Flow sheet of beneficiation process in Qaleh-Zari copper

The Qaleh-Zari copper mine is an operating underground mine in southeast Iran (latitude: 31 50 0 N, longitude: 59 0 0 E). In the beneficiation plant around 400 tpd crushed ore with copper grade of

The Complete Collection of Copper Beneficiation Reagents

2023年2月15日In the flotation process of the copper mine, the use of flotation reagents to change the surface properties of the mineral is a flexible and effective way to control the

Copper processing Roasting, smelting, and converting

Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and

Estimated Water Requirements for the Conventional Flotation

Froth flotation is part of a copper beneficiation process in which finely ground ore is placed in aerated tanks that contain a water-based solution from which a copper-sulfide-rich froth is recovered through the use of a combination of physical and chemical interactions. The remaining non-ore minerals

COPPER Copper production TU Delft

Typical equipment for crushing to about 20 cm are gyratory and cone crushers. density, and other properties are installed. Figure 4 gives an overview of a typical beneficiation process at a concentrator. In the first flotation stage, as much copper are used to process such copper-containing materials as intermediate products (e.g

Flow sheet of beneficiation process in Qaleh-Zari

The Qaleh-Zari copper mine is an operating underground mine in southeast Iran (latitude: 31 50 0 N, longitude: 59 0 0 E). In the beneficiation plant around 400 tpd crushed ore with copper grade of

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Copper accounts for 46% of all mine tailings globally, followed by gold at 21% and iron at 9%. Countries with large numbers of tailings dams include Australia, Brazil, Canada, and the United States.

Copper Beneficiation Process,Copper Refining

Copper Ore Beneficiation Technology Kaolin Beneficiation Technology and Process Flow Iron Ore Hematite Separation Process Gold CIL Production Line Scheelite Flotation Production Line Phosphate Flotation

1.1 PHASES OF A MINING PROJECT ELAW

The beneficiation process generates high-volume waste called ‘tailings,’ the residue of an ore that remains after it has been milled and the desired metals have been extracted (e.g., with cyanide (gold) or sulfuric acid (copper)). If a mining project involves the extraction of a few hundred million metric tons of mineral ore, then

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Copper beneficiation equipment, Copper ore beneficiation process

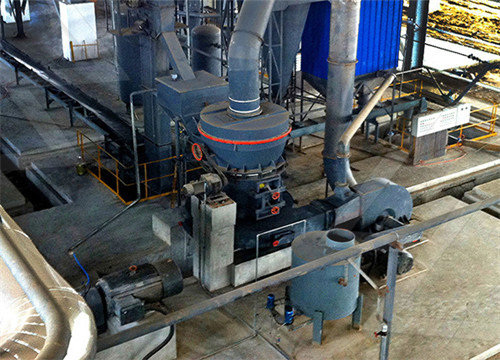

Copper beneficiation process. Communition (Crushing and Grinding) represents over 50% of the total mineral processing cost. There has been a development towards Autogenous Grinding, which is the grinding of ore by itself rather by special metallic or non-metallic grinding bodies distinct from the ore.

Used Copper Ore Beneficiation Plant in Pakistan_cnuw11670的博

Typically, the process of copper beneficiation adopts the theory that if the weights of solid particles are different, the sedimentations will be different, and the mixed ore can be classified by screw classifierCement Clinker Processing Plant . For some copper investors, they are lack of mining funds, therefore, they prefer those used copper ore

Copper beneficiation process copper mining machine

General beneficiation process: raw coal primary crushing secondary crushing storage bin feeding ball mill gradation flotation re-flotation concentration. Copper concentration generally may use an easy process: once coarse concentration, 2 or 3 occasions fine concentration, a couple of occasions scavenging.

Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process

2019年4月1日This stone analysed the life cycle environmental impacts from the beneficiation process of gold-silver-lead-zinc-copper combined production. The analysis is conducted by utilising the SimaPro software version 8.5. The life cycle assessment methodologies followed are the International Reference Life Cycle Data System (ILCD)

Metals Free Full-Text An Experimental Investigation on the

2022年3月24日Copper (Cu) and brass (Br) electrodes, each of 12.0 mm diameter (Ø), were used as machine electrodes. Figure 2 shows the fabricated samples and the tool electrodes. The straight polarity of electrodes was used during all the experimental work. Tool material, current (I), voltage (V) and pulse on time (T on) were selected as the EDM

Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process

2019年4月1日Gold, silver, lead, zinc, and copper are valuable non-ferrous metals that paved the way for modern civilisation. However, the environmental impacts from their beneficiation stage was always overlooked. This stone analysed the life cycle environmental impacts from the beneficiation process of gold-silver-lead-zinc-copper

Minerals Special Issue : Value of Mineralogical Monitoring for the

2021年10月22日copper ores; process monitoring; mineralogy; Published Papers (10 s) Download All Papers. and Reactive Silica (RxSiO 2), the main parameters of bauxite controlled in the beneficiation process are traditionally measured by laborious, expensive, and time-consuming wet chemistry methods. Machine learning is a

Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process

2019年4月1日This stone analysed the life cycle environmental impacts from the beneficiation process of gold-silver-lead-zinc-copper combined production. The analysis is conducted by utilising the SimaPro software version 8.5. The life cycle assessment methodologies followed are the International Reference Life Cycle Data System (ILCD)

Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process

2019年4月1日Gold, silver, lead, zinc, and copper are valuable non-ferrous metals that paved the way for modern civilisation. However, the environmental impacts from their beneficiation stage was always overlooked. This stone analysed the life cycle environmental impacts from the beneficiation process of gold-silver-lead-zinc-copper

Estimated Water Requirements for the Conventional Flotation

Froth flotation is part of a copper beneficiation process in which finely ground ore is placed in aerated tanks that contain a water-based solution from which a copper-sulfide-rich froth is recovered through the use of a combination of physical and chemical interactions. The remaining non-ore minerals

Copper Beneficiation Process,Copper Refining

Copper Ore Beneficiation Technology Kaolin Beneficiation Technology and Process Flow Iron Ore Hematite Separation Process Gold CIL Production Line Scheelite Flotation Production Line Phosphate Flotation

Flow sheet of beneficiation process in Qaleh-Zari

In the beneficiation plant around 400 tpd crushed ore with copper grade of 1–1.5% is processed to produce a concentrate with a copper content of 18–20%. Figure 1 shows the beneficiation...

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Copper accounts for 46% of all mine tailings globally, followed by gold at 21% and iron at 9%. Countries with large numbers of tailings dams include Australia, Brazil, Canada, and the United States.

Copper beneficiation equipment, Copper ore beneficiation process

Copper beneficiation process. Communition (Crushing and Grinding) represents over 50% of the total mineral processing cost. There has been a development towards Autogenous Grinding, which is the grinding of ore by itself rather by special metallic or non-metallic grinding bodies distinct from the ore.

Copper beneficiation process copper mining machine

General beneficiation process: raw coal primary crushing secondary crushing storage bin feeding ball mill gradation flotation re-flotation concentration. Copper concentration generally may use an easy process: once coarse concentration, 2 or 3 occasions fine concentration, a couple of occasions scavenging.

Used Copper Ore Beneficiation Plant in Pakistan_cnuw11670的博

Typically, the process of copper beneficiation adopts the theory that if the weights of solid particles are different, the sedimentations will be different, and the mixed ore can be classified by screw classifierCement Clinker Processing Plant . For some copper investors, they are lack of mining funds, therefore, they prefer those used copper ore

AP-42, CH 11.7: Ceramic Products Manufacturing US EPA

11.7.2 Process Description1,3-5 Figure 11.7-1 presents a general process flow diagram for ceramic products manufacturing. The basic steps include raw material procurement, beneficiation, mixing, forming, green machining, drying, presinter thermal processing, glazing, firing, final processing, and packaging. The following

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

sbm/sbm copper beneficiation process of copper processing

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Minerals Special Issue : Value of Mineralogical Monitoring for the

2021年10月22日copper ores; process monitoring; mineralogy; Published Papers (10 s) Download All Papers. and Reactive Silica (RxSiO 2), the main parameters of bauxite controlled in the beneficiation process are traditionally measured by laborious, expensive, and time-consuming wet chemistry methods. Machine learning is a

Beneficiation Wikipedia

Beneficiation. In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings ). There are many different types of beneficiation, with each step